Manufacturing process of nano antibacterial and mildew-proof waterborne polyurethane coating

A water-based polyurethane, antibacterial and anti-mildew technology, applied in the field of coatings, can solve the problems of inability to resist microorganisms, inability to maintain the coating effect for a long time, etc., and achieve the effects of reducing the reproduction speed, good anti-mildew performance, and physical health protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

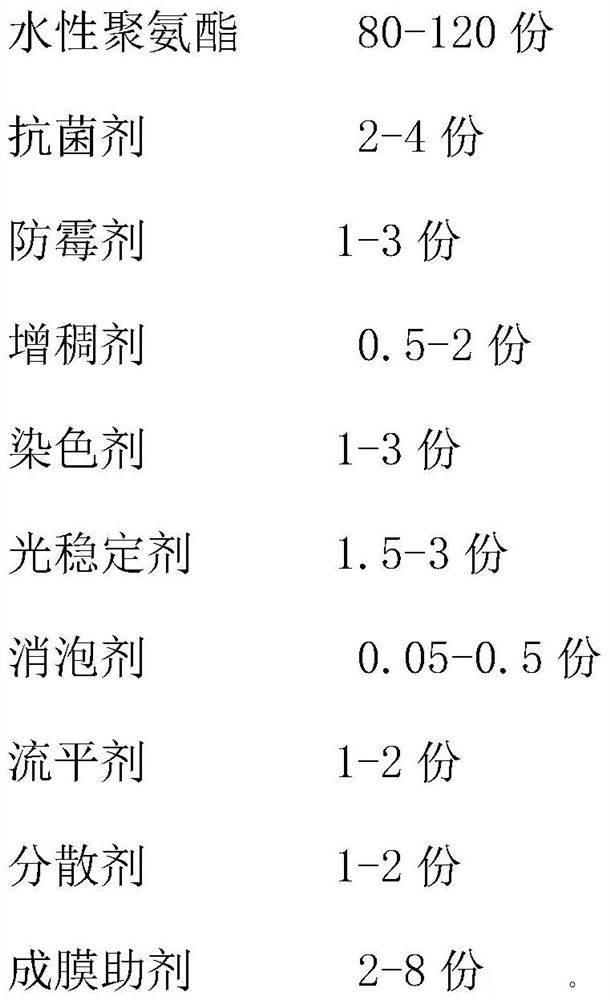

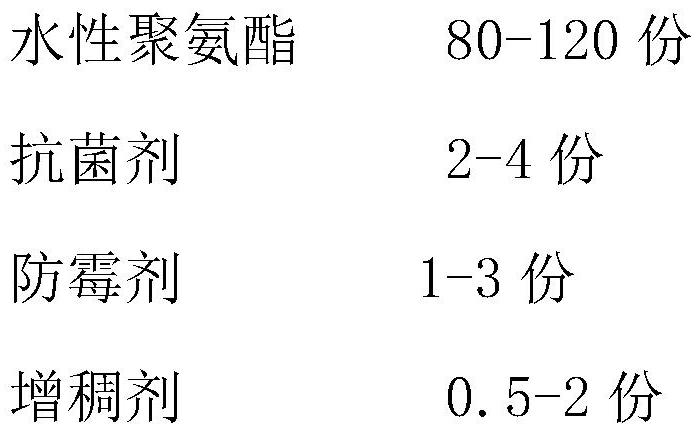

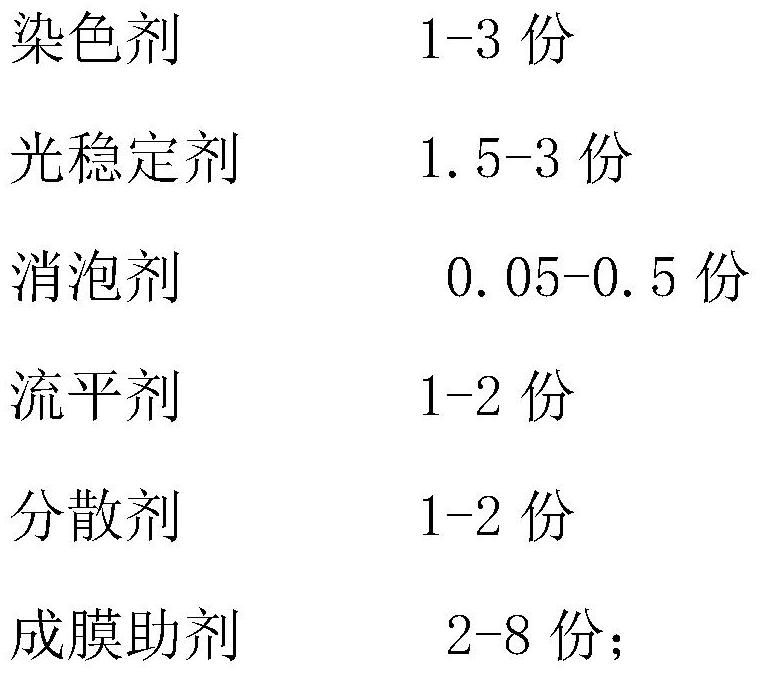

Method used

Image

Examples

Embodiment 1

[0026] First select 80 parts of water-based polyurethane and put it into the reactor for heating, then add 2 parts of antibacterial agent and 1 part of antifungal agent, heat to 85°C, then add 1 part of thickener, 2 parts of light stabilizer, and 0.5 part of defoamer and 1.5 parts of leveling agent, then heated and stirred, heated to 100°C, cooled to room temperature to obtain a mixture for later use, then added 1 part of dyeing agent, 1.5 parts of dispersant and 6 parts of film-forming aid to the mixture, at 120°C Disperse at a speed of 1800r / min for 20 minutes at a certain temperature, and then filter to obtain a nano-antibacterial and mildew-proof waterborne polyurethane coating.

Embodiment 2

[0028] In embodiment one, add following operation:

[0029] The antibacterial agent adopts nano titanium dioxide, and the antifungal agent adopts benzothiazol-3-one antifungal agent.

[0030] First select 90 parts of water-based polyurethane and put it into the reactor for heating, then add 3 parts of antibacterial agent and 2 parts of antifungal agent, heat to 85°C, then add 1 part of thickener, 2 parts of light stabilizer and 0.5 part of defoamer and 1.5 parts of leveling agent, then heated and stirred, heated to 100°C, cooled to room temperature to obtain a mixture for later use, then added 1 part of dyeing agent, 1.5 parts of dispersant and 6 parts of film-forming aid to the mixture, at 120°C Disperse at a speed of 1800r / min for 20 minutes at a certain temperature, and then filter to obtain a nano-antibacterial and mildew-proof waterborne polyurethane coating.

Embodiment 3

[0032] In embodiment two, add following operation:

[0033] The thickener is any one of hydroxyethyl cellulose or non-ionic associative thickeners, and the light stabilizer is any one of benzophenones, salicylates and benzotriazoles kind.

[0034] First select 95 parts of water-based polyurethane and put it into the reactor for heating, then add 4 parts of antibacterial agent and 2 parts of antifungal agent, heat to 90°C, then add 1 part of thickener, 2 parts of light stabilizer and 0.5 part of defoamer and 1.5 parts of leveling agent, then heated and stirred, heated to 100°C, cooled to room temperature to obtain a mixture for later use, then added 1 part of dyeing agent, 1.5 parts of dispersant and 6 parts of film-forming aid to the mixture, at 120°C Disperse for 25 minutes at a speed of 2000r / min at a certain temperature, and then filter to obtain a nano-antibacterial and mildew-proof waterborne polyurethane coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com