Heat supply and light supplement microalgae culture system and culture method based on thermal power plant

A technology of aquaculture system and thermal power plant, which is applied in the field of microalgae cultivation, can solve the problems of light conditions and geographical restrictions, waste, and high energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

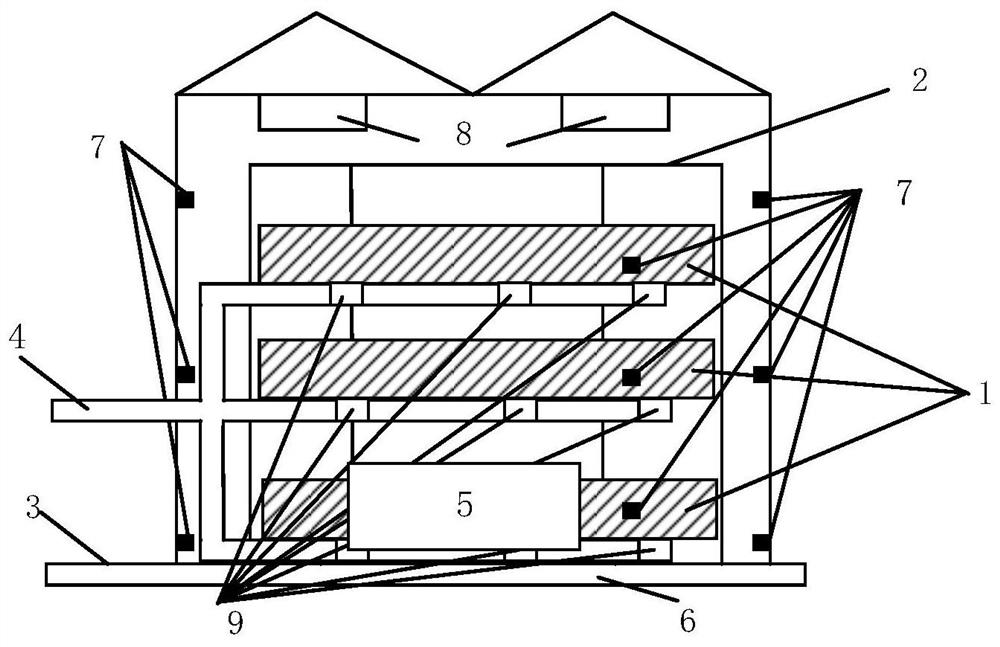

[0039] refer to figure 1 , a microalgae breeding system for heating and supplementing light in a thermal power plant, including a thermal power plant boiler, a steam turbine, a generator and its auxiliary equipment, and also includes a thermal power plant waste heat heating heat exchanger, a low-temperature heating pipeline 3, a thermal power plant surplus power supply line and Supplementary light lighting unit 8, microalgae cultivation water tank 1, waste heat heating and cooling device 5 in the microalgae cultivation workshop, and sensors related to the above-mentioned devices.

[0040] Among them, the waste heat heating heat exchanger of the thermal power plant transmits the waste heat of the thermal power plant to the waste heat heating and cooling device 5 in the microalgae breeding plant through the low-temperature heating pipeline 3, and the waste heat heating and cooling device 5 supplies heat to the microalgae breeding plant.

[0041] The supplementary light lighting ...

Embodiment 2

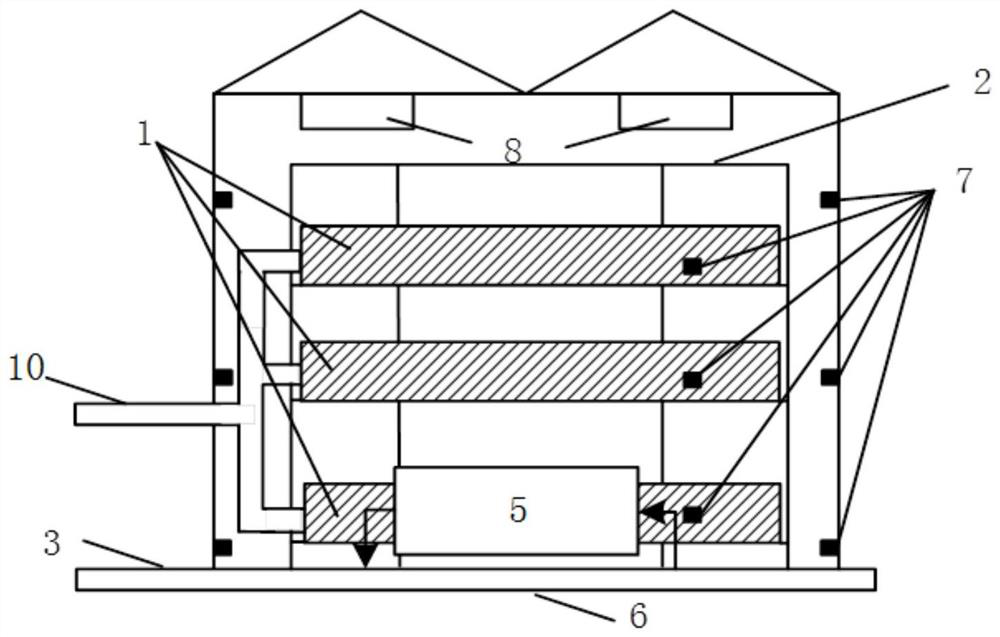

[0049] refer to figure 2 , refer to figure 1 , a microalgae culture system for heating and supplementing light in a thermal power plant, including a thermal power unit boiler, a steam turbine, a generator and its auxiliary equipment, and also includes a thermal power plant waste heat heating heat exchanger, a sodium bicarbonate solution supply pipeline 10, and a low-temperature heating pipeline 3. Thermal power plant residual power supply line and supplementary lighting unit 8, microalgae cultivation water tank 1, waste heat heating and cooling device 5 in the microalgae cultivation workshop, and sensors related to the above devices.

[0050] Among them, the waste heat heating heat exchanger of the thermal power plant transmits the waste heat of the thermal power plant to the waste heat heating and cooling device 5 in the microalgae breeding plant through the low-temperature heating pipeline 3, and the waste heat heating and cooling device 5 supplies heat to the microalgae br...

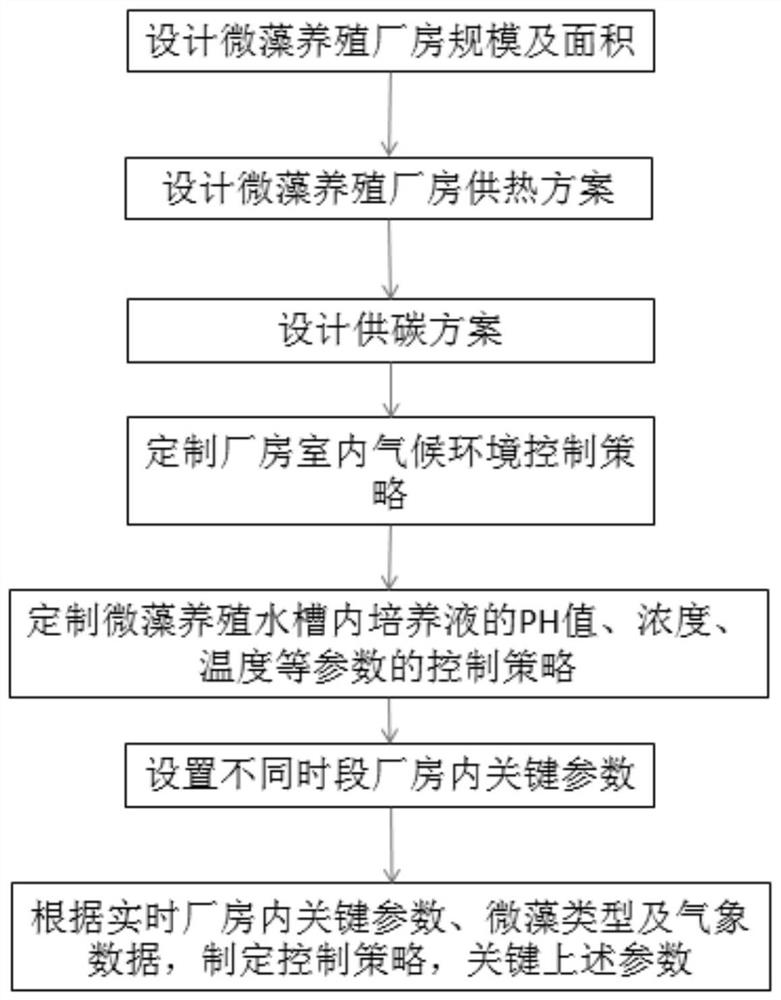

Embodiment 3

[0059] A microalgae culture system for heating and supplementing light in a thermal power plant, including a thermal power plant boiler, a steam turbine, a generator and its auxiliary equipment, and also includes a thermal power plant waste heat heating heat exchanger, a low-temperature heating pipeline 3, and a sodium bicarbonate solution supply pipeline 10 , thermal power plant residual power supply line and supplementary lighting unit 8, microalgae cultivation water tank 1, waste heat heating and cooling device 5 in the microalgae cultivation workshop, and sensors related to the above-mentioned devices.

[0060] Among them, the waste heat heating heat exchanger of the thermal power plant transmits the waste heat of the thermal power plant to the waste heat heating and cooling device 5 in the microalgae breeding plant through the low-temperature heating pipeline 3, and the waste heat heating and cooling device 5 supplies heat to the microalgae breeding plant. A multi-layer cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com