Positive plate for solid-state battery, and preparation method and application thereof

A solid-state battery, positive electrode technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve problems such as poor rate performance, poor mechanical strength, and increased battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

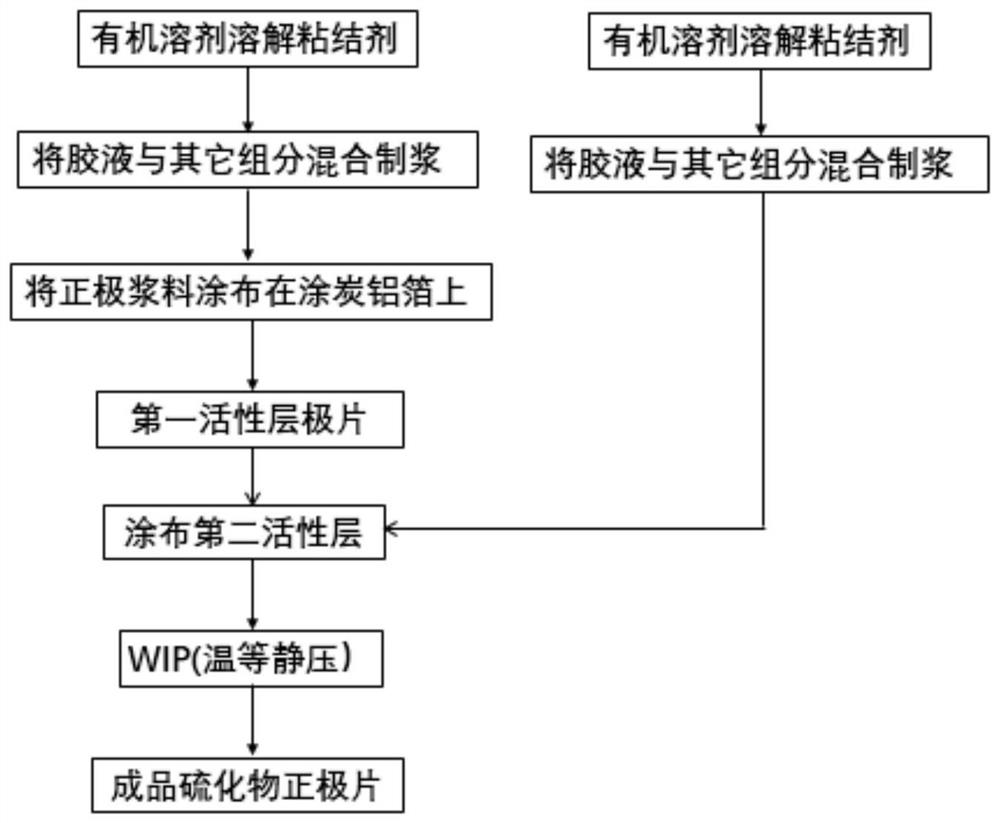

[0055] This embodiment provides a positive electrode sheet for a solid-state battery, the preparation process flow chart of the positive electrode sheet for a solid-state battery is as follows figure 1 As shown, the specific preparation method is as follows:

[0056] (1) Take NCM811@Li 2 ZrO 3 The mass ratio of :LSPS:SP:PVDF21216 is 75:7:9:9 for later use, and then THF is used to dissolve PVDF21216. The solid content of the glue is 6%. After stirring and homogenizing the glue with other components, the solid content is obtained. The first slurry is 73%, and the first slurry is coated on a carbon-coated aluminum foil and dried at 80° C. and hot-rolled to obtain a first active layer with a thickness of 20 μm;

[0057] (2) Take NCM811@Li 2 ZrO 3 :LSPCl:(SP:VGCF):SBS mass ratio is 60%: 35%: 2% (SP:CNT=3:7): 3% for later use, then use anisole to dissolve SBS, the solid content of the glue is 7% After stirring, mixing and homogenizing the glue solution with the materials of oth...

Embodiment 2

[0060] This embodiment provides a positive electrode sheet for a solid-state battery, the preparation process flow chart of the positive electrode sheet for a solid-state battery is as follows figure 1 As shown, the specific preparation method is as follows:

[0061] (1) Take NCM811@Li 2 NbO 3 :LSPCl:(SP:CNT):PVDF-LBG mass ratio is 85:5:5(SP:CNT=9:1):5 for later use, then use cyclohexanone to dissolve PVDF-LBG, the solid content of the glue is 4.5% , after mixing and homogenizing the glue solution with the materials of other components, the first slurry with a solid content of 75% is obtained, and the first slurry is coated on a carbon-coated aluminum foil at 80° C. and dried by hot rolling, The thickness of the first active layer is obtained to be 25 μm;

[0062] (2) Take NCM811@Li 2 NbO 3 :LGPS:(SP:VGCF):SEBS mass ratio is 50%: 45%: 2% (SP:CNT=4:6): 3% for standby, then use anisole to dissolve SEBS, the solid content of the glue is 6.5% After stirring, mixing and homog...

Embodiment 3

[0065] This embodiment provides a positive electrode sheet for a solid-state battery, the preparation process flow chart of the positive electrode sheet for a solid-state battery is as follows figure 1 As shown, the specific preparation method is as follows:

[0066] (1) Take NCM811@LiPO3: LSPS: (SP: VGCF): PVDF-HVS900 with a mass ratio of 89:4:4 (SP: VGCF=9:1):3 for later use, and then use cyclohexanone to dissolve PVDF-HVS900, The solid content of the glue solution is 5%. After the glue solution is stirred, mixed and homogenized with the materials of other components, the first slurry with a solid content of 71% is obtained, and the first slurry is coated on a carbon-coated aluminum foil at 80°C After drying and hot rolling, the thickness of the first active layer is 10 μm;

[0067] (2) Take NCM811@Li 2 NbO 3 :LSPCl:(AB:VGCF:graphene): PVDF-LBG mass ratio is 68%: 29%: 2% (AB:VGCF:graphene=3:5:2): 1% for standby, then use tetrahydrofuran to dissolve PVDF -LBG, the solid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com