Centrifugal extraction separation method and separation device in preparation process of nitro-azide compounds

A technology of nitro azide and separation method, which is applied in the direction of separation method, chemical instrument and method, solvent extraction, etc. It can solve the problems of hidden safety hazards of production equipment, long standing time, low mass transfer efficiency, etc., and achieve the reduction of residence time , the device is highly efficient and energy-saving, and the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

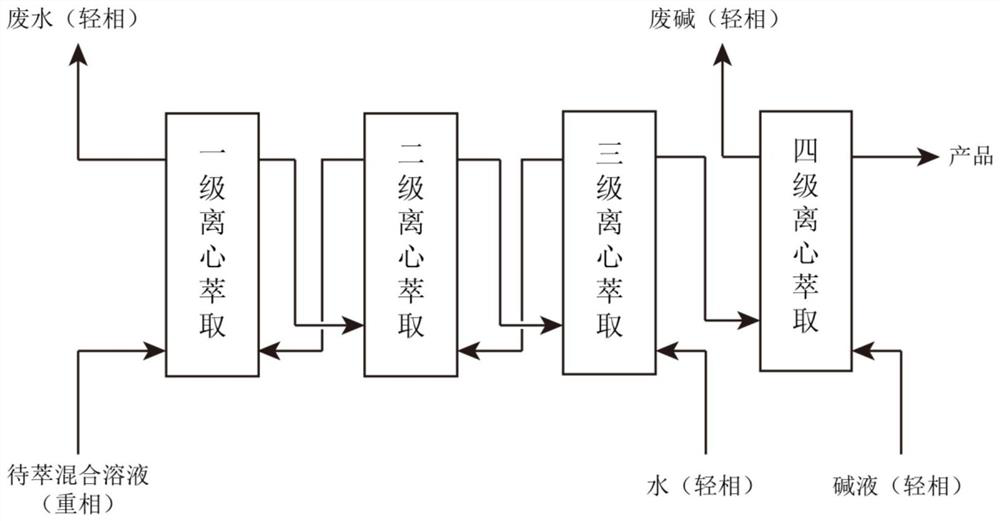

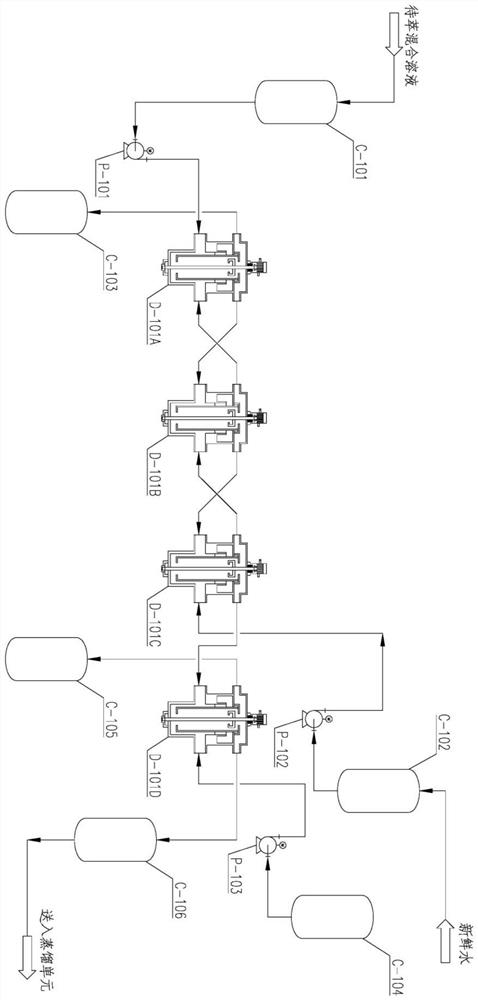

[0058] A national defense chemical research institute in Xi'an carried out a pilot test using the method and device of the present invention, and applied the solvent separation unit in the preparation process of diazide nitramine (DIANP) on its propellant and explosive formula production line. figure 2 The process flow chart of the comprehensive application of the centrifugal extraction and separation method in the preparation process of nitroazide compounds is shown. After the treatment, the pure mixed solution of azide nitramine and dichloromethane enters the downstream unit. There is no waste water and waste residue during the treatment process. At the same time, it realizes resource management and produces significant economic benefits. Its specific operation process and effect are as follows:

[0059] (1) Test conditions

[0060] The composition of the material to be extracted (one batch) is basically as follows: the total mass of the liquid to be extracted is about 119...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com