A kind of magnetic adsorbent and preparation method thereof

A magnetic adsorbent, surfactant technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of high use cost, difficult regeneration, easy loss, etc., to reduce economic costs, Select the effect of improving the adsorption capacity and enhancing the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A magnetic biosorbent with high adsorption capacity and a preparation method thereof, comprising the following steps:

[0022] (1) Preparation of carboxylated Fe by solvothermal method 3 o 4 magnetic nanoparticles. Weigh 0.4 g sodium citrate, 2.70 g FeCl 3 ·6H 2 O and 7.40 g of ammonium acetate were placed in a 250 mL three-necked flask, then added to 75 mL of ethylene glycol, and ultrasonically treated for 30 min to obtain a yellow mixture solution. The three-necked flask was transferred to an oil bath, and N 2 , heated to 170 °C, and mechanically stirred at constant temperature for 1 h to obtain a reddish-brown solution. Then the solution was transferred to a reaction kettle and placed in an oven at 200 °C for 16 h. After the reaction was completed, the reactor was taken out and cooled to room temperature, the product was separated by a magnet, washed three times with ethanol and water respectively, and the washed product was vacuum-dried at 50 °C for 24 h.

[0...

Embodiment 2

[0026] A magnetic biosorbent with high adsorption capacity and a preparation method thereof, comprising the following steps:

[0027] (1) Preparation of carboxylated Fe by solvothermal method 3 o 4 magnetic nanoparticles. Weigh 0.4 g sodium citrate, 2.70 g FeCl 3 ·6H 2 O and 7.40 g of ammonium acetate were placed in a 250 mL three-necked flask, then added to 75 mL of ethylene glycol, and ultrasonically treated for 30 min to obtain a yellow mixture solution. The three-necked flask was transferred to an oil bath, and N 2 , heated to 170 °C, and mechanically stirred at constant temperature for 1 h to obtain a reddish-brown solution. Then the solution was transferred to a reaction kettle and placed in an oven at 200 °C for 16 h. After the reaction was completed, the reactor was taken out and cooled to room temperature, the product was separated by a magnet, washed three times with ethanol and water respectively, and the washed product was vacuum-dried at 50 °C for 24 h.

[0...

Embodiment 3

[0031] A magnetic biosorbent with high adsorption capacity and a preparation method thereof, comprising the following steps:

[0032] (1) Preparation of carboxylated Fe by solvothermal method 3 o 4 magnetic nanoparticles. Weigh 0.4 g sodium citrate, 2.70 g FeCl 3 ·6H 2 O and 7.40 g of ammonium acetate were placed in a 250 mL three-necked flask, then added to 75 mL of ethylene glycol, and ultrasonically treated for 30 min to obtain a yellow mixture solution. The three-necked flask was transferred to an oil bath, and N 2 , heated to 170 °C, and mechanically stirred at constant temperature for 1 h to obtain a reddish-brown solution. Then the solution was transferred to a reaction kettle and placed in an oven at 200 °C for 16 h. After the reaction was completed, the reactor was taken out and cooled to room temperature, the product was separated by a magnet, washed three times with ethanol and water respectively, and the washed product was vacuum-dried at 50 °C for 24 h.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

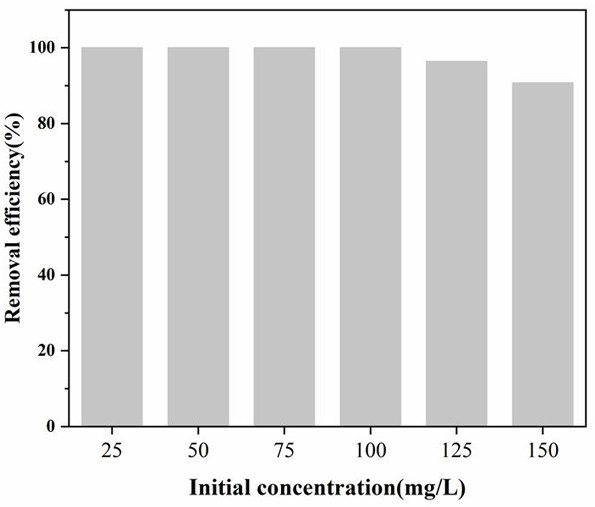

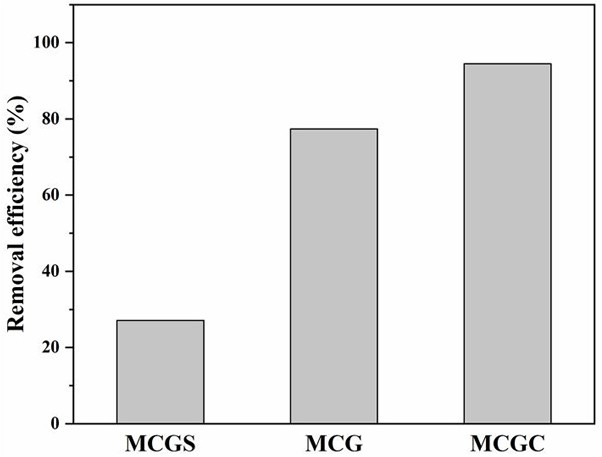

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com