In-situ polymerization method modified anion exchange resin as well as preparation method and application thereof

A technology of exchange resin and in-situ polymerization, which is applied in the fields of chemistry and environment, can solve the problems of great influence of other ions and limited adsorption capacity, etc., and achieve the effect of improving adsorption capacity, increasing positive charge, and improving adsorption treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

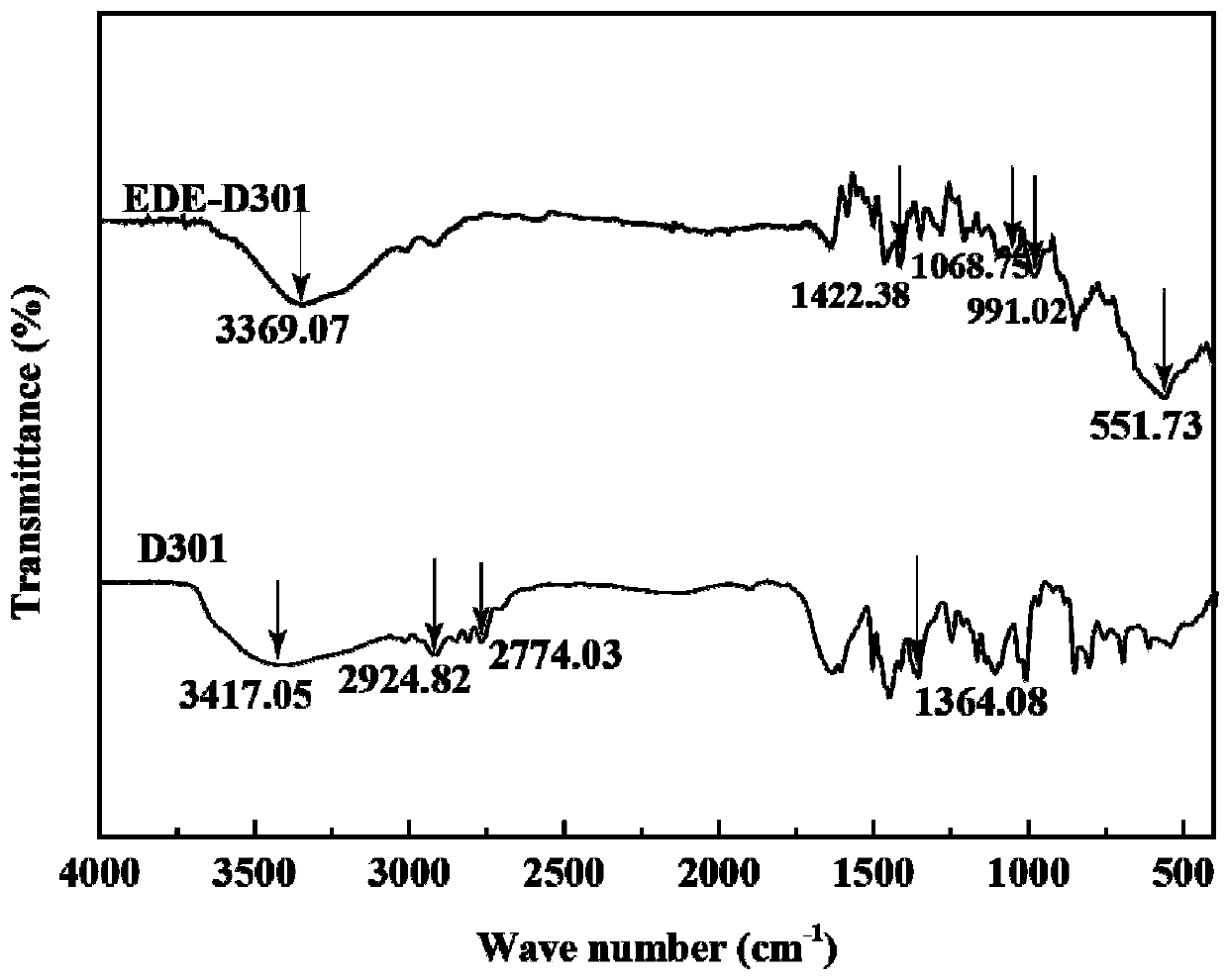

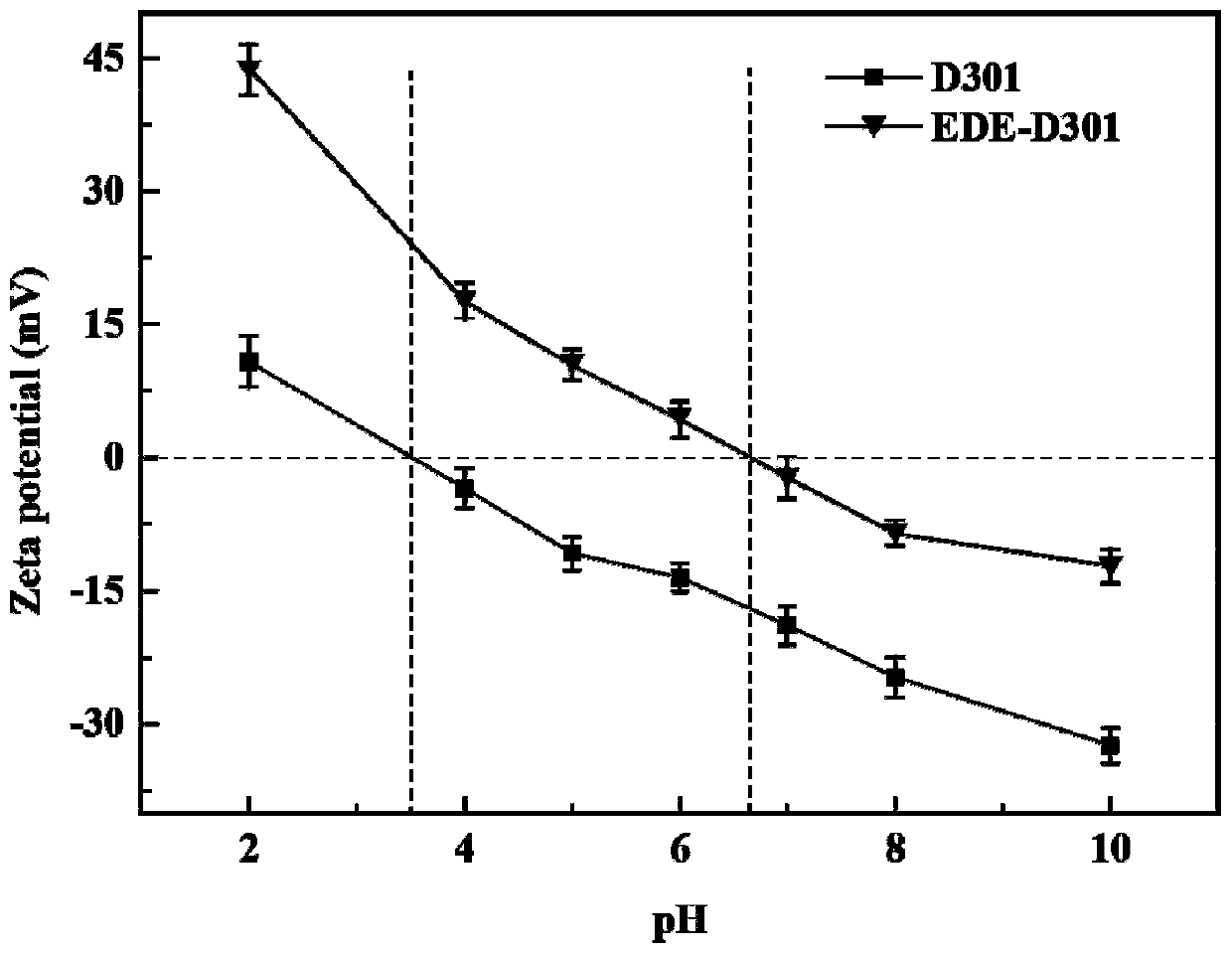

[0040] The preparation method of in-situ polymerization modified anion exchange resin, the steps are as follows:

[0041] (1) Add 25.1 mL of dimethylamine aqueous solution into a three-necked flask with a stirring and condensing reflux device, and cool in an ice-water bath to reduce the temperature of dimethylamine to 8° C., and the mass concentration of dimethylamine aqueous solution is 40%;

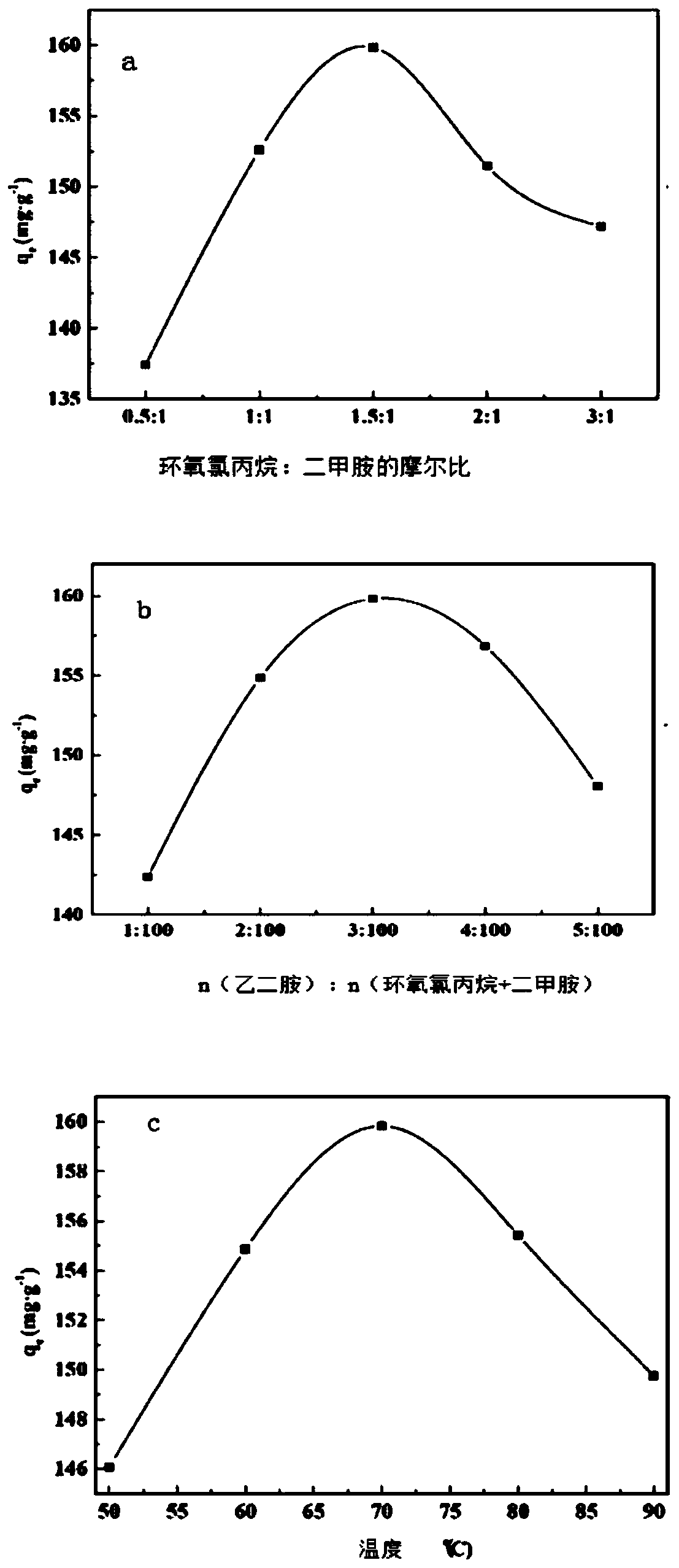

[0042] (2) Weigh 1 g of the pretreated weakly basic anion exchange resin and place it in aqueous dimethylamine solution. With stirring, add 58.75 mL of epichlorohydrin dropwise with a constant pressure separating funnel to make the epichlorohydrin : The molar ratio of dimethylamine=1.5:1, control the dropping speed, the dropping time is controlled at 2h, strengthen cooling simultaneously, make the temperature in the reactor be controlled at 15 ℃;

[0043] (3) Continue to add 2.5 mL of ethylenediamine dropwise, so that n (ethylenediamine): n (epichlorohydrin + dimethylamine) = 3:100, the...

Embodiment 2

[0049] With the preparation method of the in-situ polymerization method modified anion exchange resin described in embodiment 1, difference is:

[0050] The amount of epichlorohydrin in step (2) is 19.58mL, and the molar ratio of epichlorohydrin: dimethylamine is 0.5:1.

[0051] Adsorb the Cr(VI) solution of 50mL, 100mg / L, add the weakly basic anion exchange resin modified in 0.03g embodiment 2, set the temperature of the constant temperature oscillation box to be 25°C, and the rotating speed is 150r / min. The removal rate of Cr(VI) is 80%, and the adsorption capacity is 137mg·g -1 .

Embodiment 3

[0053] With the preparation method of the in-situ polymerization method modified anion exchange resin described in embodiment 1, difference is:

[0054] The amount of epichlorohydrin in step (2) was 117.50 mL, and the molar ratio of epichlorohydrin: dimethylamine was 3:1.

[0055] Adsorb the Cr(VI) solution of 50mL, 100mg / L, add the weakly basic anion exchange resin modified in 0.03g embodiment 3, set the temperature of the constant temperature oscillation box to be 25°C, and the rotating speed is 150r / min. The removal rate of Cr(VI) is 86%, and the adsorption capacity is 147mg·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com