Glass fiber reinforced nylon material and preparation method thereof

A glass fiber and nylon technology is applied in the field of glass fiber reinforced nylon materials and their preparation, which can solve the problems of high torque, high cost of high-end amino nylon, and low processing efficiency, and achieves low torque, improved hydrolysis resistance, and improved processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] For the above glass fiber reinforced nylon material, the present application also provides a preparation method of the glass fiber reinforced nylon material. The preparation method of the glass fiber reinforced nylon material comprises the following steps:

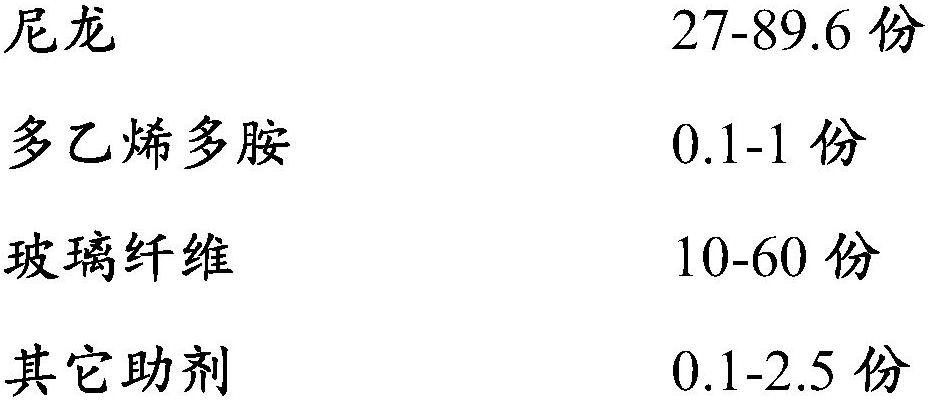

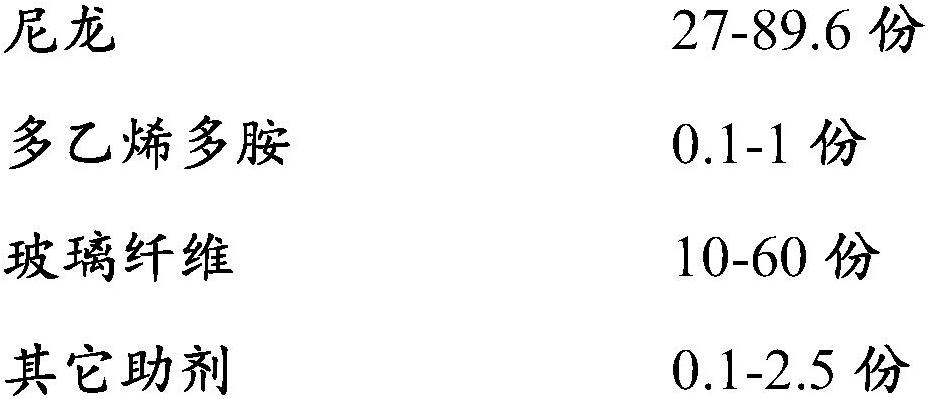

[0039] In parts by weight, 27-89.6 parts of nylon, 0.1-1 part of polyethylene polyamine, 0.1-2.5 parts of other auxiliary agents are uniformly mixed by a mixer to obtain a mixture;

[0040] The mixture is added to a twin-screw extruder for melt blending, and 10-60 parts of glass fibers are added by side feeding to extrude strands;

[0041] The material strip is cut into pellets by a pelletizer, dried by an elevator, and packaged to obtain a finished product.

[0042] Preferably, the extrusion temperature of the strip is 240-320°C,

[0043] Preferably, the screw speed of the twin-screw extruder is 300-700 rpm.

[0044] All the above-mentioned optional technical solutions can be combined arbitrarily to form optiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com