Application of a kind of phosphoric acid compound

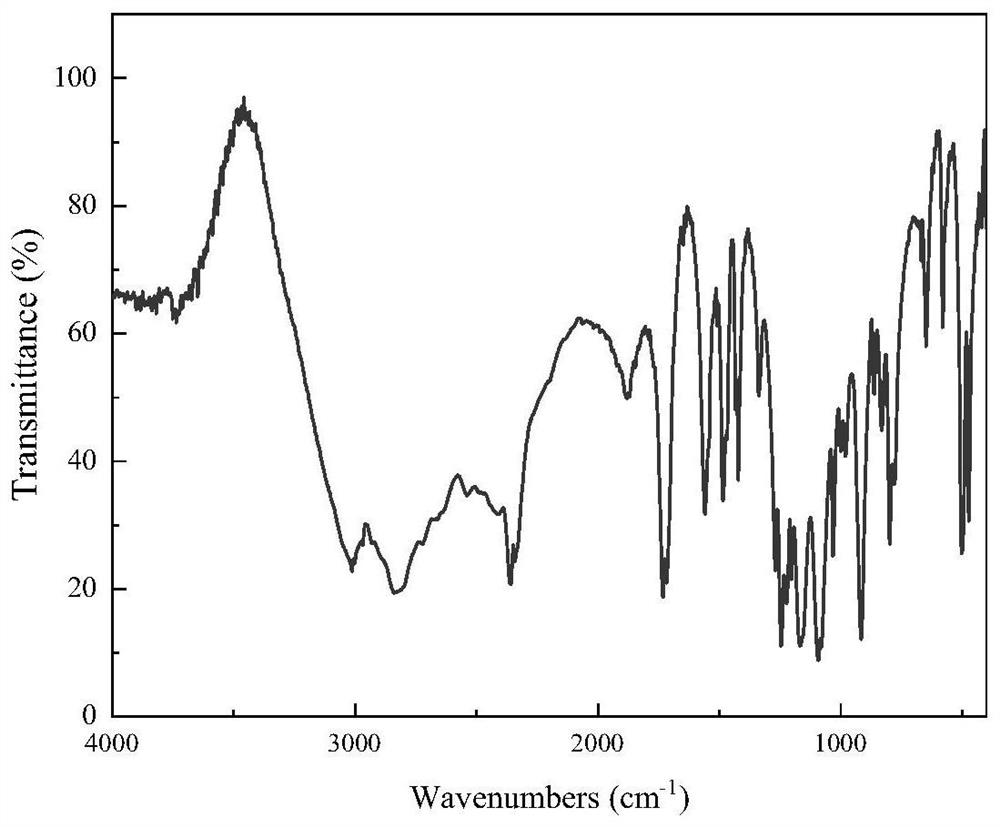

A phosphonic acid and compound technology, applied in solid separation, flotation and other directions, can solve the problems of low grade and recovery rate of useful concentrate, difficult separation, etc., to avoid accompanying flotation, less dosage, tailings and tailings. The effect of easy water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

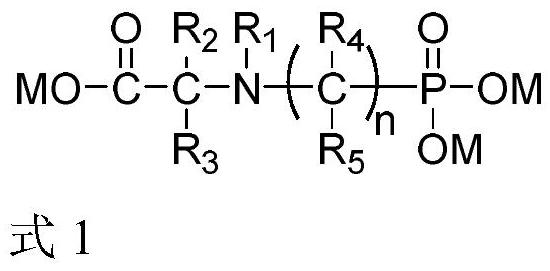

[0064] Inhibitor synthesis steps: liquid ammonia, It was mixed with cyclohexamethylenetetramine in a molar ratio of 2.0:1.0:0.1, reacted at 70°C for 2.5h, and then added with equimolar After 8h of reaction, add ethanol and centrifuge to obtain the inhibitor of formula 1-A (the preparation method of this agent does not constitute the limitation of the protection scope of the present invention, and it can also be prepared by other existing means, or existing commercial products can be used. ).

[0065] To use the inhibitor of formula 1-A (also referred to as inhibitor in this case) in the flotation of scheelite, the specific steps are as follows:

[0066] 1) Preparation of flotation pulp: add 2 g of mixed ore (scheelite and calcite mass ratio of 1:1) with a particle size of -74+38 μm and 35 ml of deionized water into the flotation cell, and stir at 1704 r / min. 2min to get flotation pulp;

[0067] 2) Add inhibitor and collector (sodium oleate) in turn, wherein the amount o...

Embodiment 2

[0073] The synthesis procedure of the inhibitor was the same as that of Example 1. The inhibitor was used in the flotation of a scheelite ore in Chenzhou, Hunan, where the scheelite grade of the ore was WO 3 0.40%, calcite grade CaCO 3 is 11.02%, including the following steps:

[0074] 1) Crushing the scheelite ore, and grinding the ore with a ball mill to a fineness of -74μm, which accounts for 75% of the ore quality;

[0075] 2) Prepare the ore powder into ore pulp with a concentration of 40% (mass content), add 250g / t inhibitor (formula 1-A), stir for 3min and then add 150g / t sodium oleate as a collector, stir for 3min Adjust the pH of the pulp to 11 with sodium carbonate;

[0076] 3) Inflatable flotation for 6 minutes, and after one roughing, scheelite rough concentrate is obtained. Among them, the tungsten grade is WO 3 2.15%, recovery 85.16%; CaCO 3 was 4.02%, and the recovery rate was 5.74%.

Embodiment 3

[0078] Inhibitor synthesis steps: liquid ammonia, Mixed with cyclohexamethylenetetramine in a molar ratio of 2.2:0.9:0.1, reacted at 75°C for 2.0h, and then added with equimolar After 7h of reaction, add ethanol and centrifuge to get the inhibitor

[0079] This embodiment is directed to a certain low-grade scheelite in Jiangxi, where the grade of scheelite is WO 3 0.21%, calcite grade CaCO 3 is 14.32%, and the specific steps are as follows:

[0080] 1) Crushing the scheelite ore, and grinding the ore with a ball mill to a fineness of -0.074mm, which accounts for 70% of the ore quality;

[0081] 2) Prepare the ore powder into pulp, add 200g / t inhibitor (formula 1-B), add 100g / t sodium oleate after stirring for 3min, and adjust the pH of the pulp to 8 with hydrochloric acid after stirring again for 3min;

[0082] 3) Air-filled flotation for 5 minutes to obtain scheelite coarse concentrate; then the scheelite coarse concentrate is subjected to four beneficiation, wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com