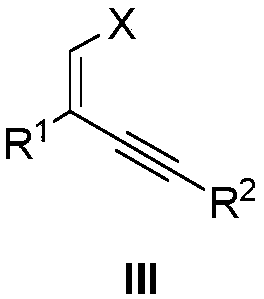

Terminal alkenyl halogenated 1,3-enyne compound as well as preparation method and application thereof

A compound, the technology of olefin halogenation, applied in the field of terminal olefin halogenation, can solve the problems of few alternative methods and complex synthesis routes, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of alkyne halide (I)

[0031] (1) Preparation of phenylalkyne chloride (I-1)

[0032] The reaction formula is as follows:

[0033]

[0034] Phenylacetylene (II-1) (2.042 g, 20 mmol), cesium carbonate (3.84 g, 22 mmol), and tetra-n-butylammonium chloride (278 mg, 1 mmol) were added to a round-bottomed flask of carbon tetrachloride at 70 The reaction was stirred at °C for 7 hours. After the reaction was completed, n-hexane (100 mL) was added to dilute, and the filtrate was collected by filtration. The filtrate was evaporated under reduced pressure in a 40° C. water bath using a rotary evaporator to remove the solvent. Finally, column chromatography (mobile phase: petroleum ether) obtained the colorless target compound (I-1) with a yield of 83.0%. Its structure is characterized as follows:

[0035] 1 H NMR (600MHz, CDCl 3 )δ7.36-7.33(m,2H),7.24-7.20(m,3H). 13 C NMR (150MHz, CDCl 3 ) δ131.9,128.6,128.3,122.1,69.4,68.0.GC-MS(EI):m / z 136[M ...

Embodiment 2

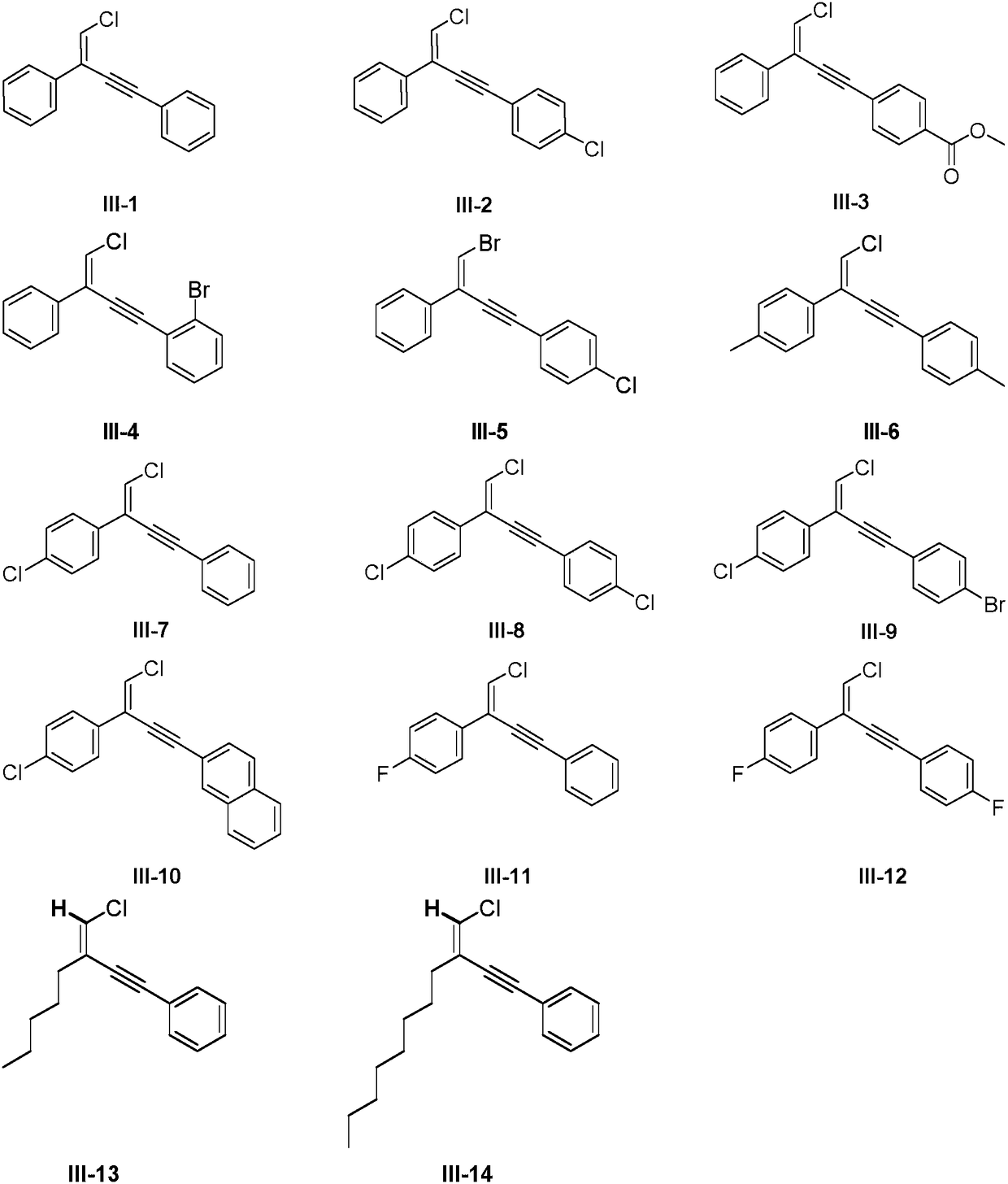

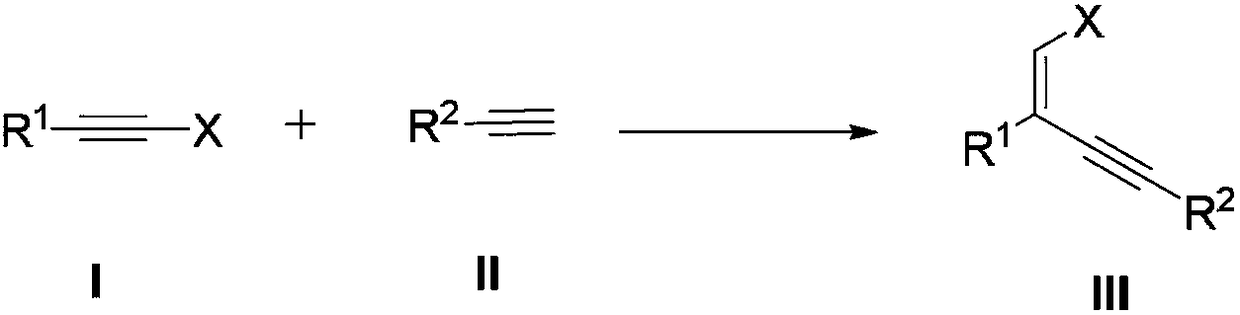

[0049] Example 2: Preparation of terminal alkene chlorinated 1,3-enyne compound (III-1)

[0050] The reaction formula is as follows:

[0051]

[0052] To the reaction flask was added IPrAuCl (5mol%, 9.3mg, 0.015mmol), NaBArF 4 (10mol%, 26.6.3mg, 0.03mmol), first dissolve with 2.0mL dichloroethane, add phenylacetylene chloride (I-1) (41.0mg, 0.3mmol) to the reaction flask at 15°C, and stir , phenylacetylene (II-1) (30.6 mg, 0.3 mmol) was added thereto, and the reaction was stirred at 15° C. for 10 hours. The reaction process was monitored by TLC plate. After the reaction is completed, filter, wash the filter cake with dichloromethane (0.6 mL×2), combine the filtrates, evaporate the solvent, and finally purify by column chromatography (mobile phase is n-hexane, Rf=0.5-0.7) to obtain terminal alkene Chlorinated 1,3-enyne compound (III-1), yield 91%.

[0053] Its structure is characterized as follows:

[0054] 1 H NMR (600MHz, CDCl 3 )δ7.66(d,J=1.2Hz,1H),7.65-7.62(m,3H),7...

Embodiment 3

[0055] Example 3: Preparation of terminal alkene chlorinated 1,3-enyne compounds (III-2)

[0056] The reaction formula is as follows:

[0057]

[0058] The phenylacetylene (II-1) (30.6 mg, 0.3 mmol) in Example 2 was replaced with p-chlorophenylacetylene (II-2) (41.0 mg, 0.3 mmol), and other operations were the same as in Example 2, and finally the terminal was obtained. Alkenyl chlorinated 1,3-enyne compound (III-2), yield 91%. Its structure is characterized as follows:

[0059] 1 H NMR (600MHz, CDCl 3 )δ7.55(d,J=7.0Hz,2H),7.46(d,J=8.5Hz,2H),7.36-7.28(m,5H),6.82(s,1H). 13 C NMR (150MHz, CDCl 3 )δ135.65,134.92,132.98,128.74,128.71,128.65,126.85,126.18,124.16,121.19,97.34,85.64.GC-MS(EI):m / z 272[M + ].IRν max (cm -1 ): 3414, 1627, 1486, 1388, 1093, 828, 696.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com