Microcapsule soil conditioner and preparation method thereof

A technology of soil conditioner and microcapsule, which is applied in the field of microcapsule soil conditioner and its preparation, can solve the problems of cumbersome preparation methods and low drug loading of soil conditioner, achieve simple preparation process, improve soil physical and chemical properties, Excellent biocompatibility and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

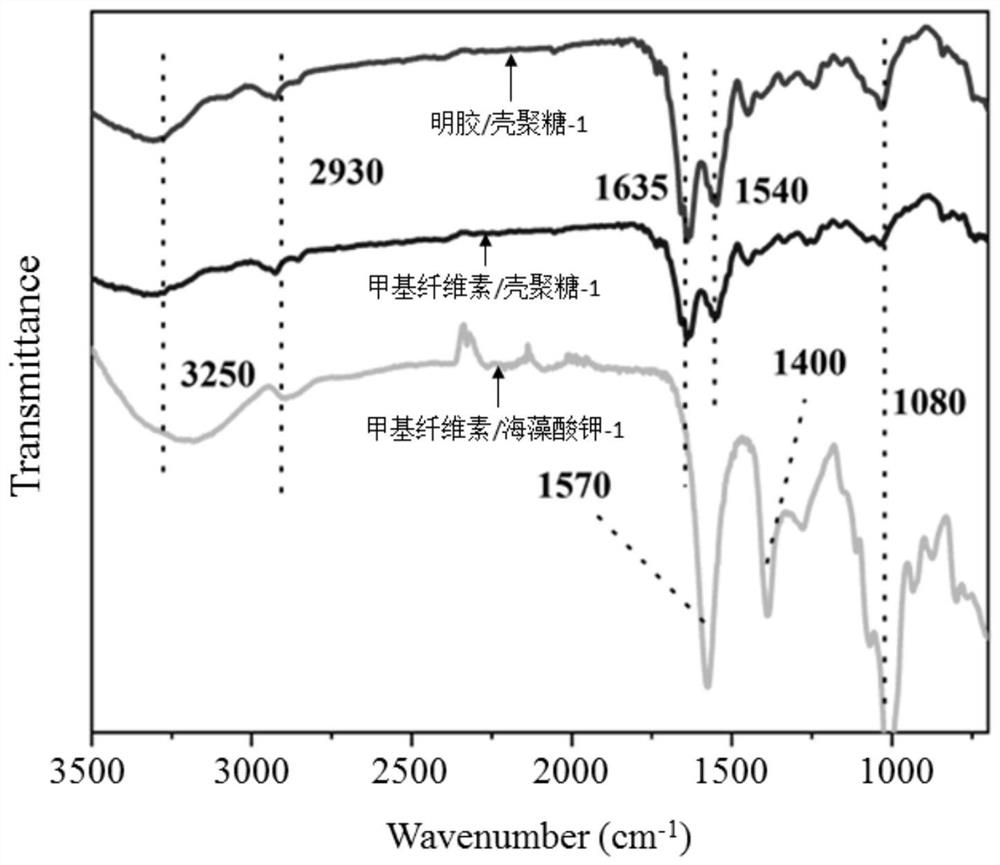

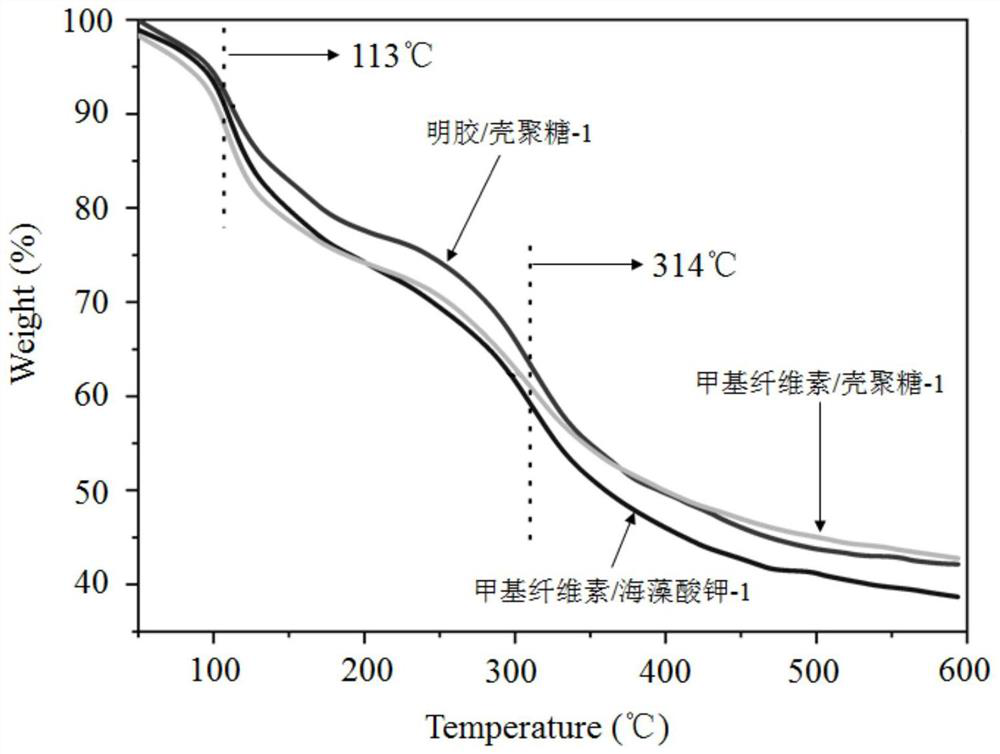

[0033] A kind of microcapsule soil conditioner, its preparation method comprises the following steps:

[0034] A1, mix 10-20g gelatin with 100mL deionized water evenly to obtain a gelatin solution; mix 1-5g chitosan with 100mL deionized water evenly and drop an appropriate amount of acetic acid to obtain a chitosan solution;

[0035] A2, mix gelatin solution and chitosan solution with volume ratio (1-9): 3, obtain mixed solution, then add fulvic acid, attapulgite, magnesium ammonium phosphate, magnesium sulfate to mixed solution, and through mechanical stirring and After ultrasonic treatment, a uniformly mixed raw material solution is obtained; the mass concentration of fulvic acid in the raw material solution is 1-5 mg / mL, the mass concentration of attapulgite is 80-120 mg / mL, the mass concentration of ammonium magnesium phosphate is 80-120 mg / mL, sulfuric acid Magnesium concentration 10-30mg / mL;

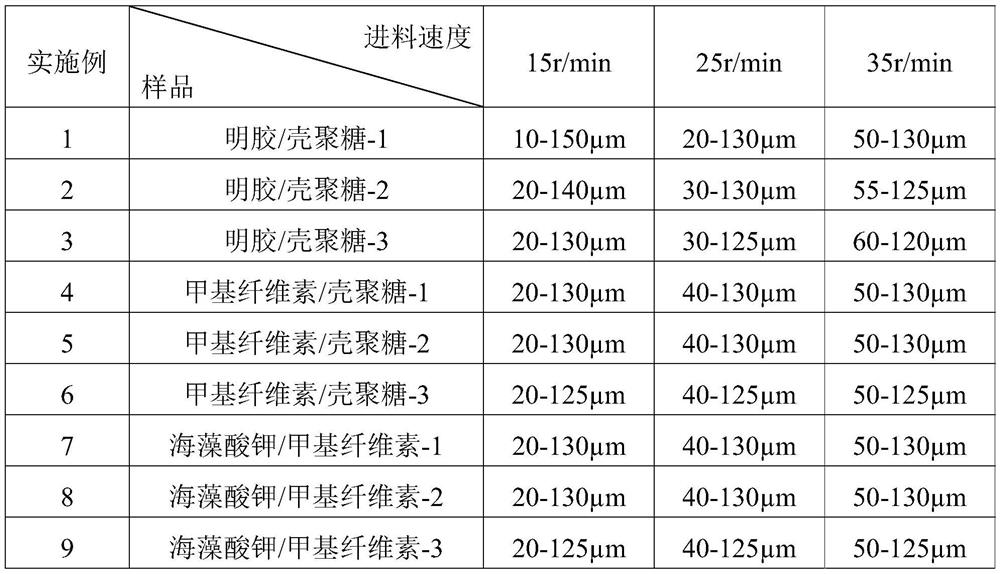

[0036] A3, put the raw material solution in a spray dryer, spray dry with a s...

Embodiment 1

[0047] A kind of microencapsulated soil conditioner, its preparation method comprises the following steps:

[0048] 1) Mix 15g of gelatin with 100mL of deionized water to obtain a gelatin solution; mix 3g of chitosan with 100mL of deionized water to obtain a chitosan solution;

[0049] 2) Mix the gelatin solution and the chitosan solution at a volume ratio of 15:5 to obtain a mixed solution, then add fulvic acid, attapulgite, magnesium ammonium phosphate, and magnesium sulfate to the mixed solution, and after mechanical stirring and ultrasonic treatment in turn, Obtain a uniformly mixed raw material solution; in the raw material solution, the mass concentration of fulvic acid is 3 mg / mL, the mass concentration of attapulgite is 100 mg / mL, the mass concentration of ammonium magnesium phosphate is 100 mg / mL, and the concentration of magnesium sulfate is 10 mg / mL;

[0050] 3) The raw material solution is placed in a spray dryer, spray-dried at a spray pressure of 1.5 MPa, a feed ...

Embodiment 2

[0052] The mixing volume ratio of gelatin solution and chitosan solution is 10:10 in the present embodiment, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com