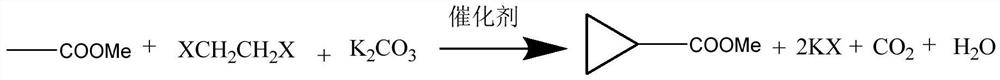

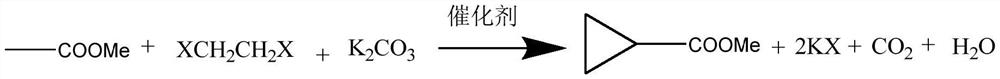

Preparation method of cyclopropylamine intermediate cyclopropanecarboxylic acid methyl ester

A technology for methyl cyclopropanate and intermediates, which is applied in the field of preparation of methyl cyclopropylamine intermediates, can solve the problems of high requirements for reaction equipment, dangerous operation, and difficult product separation, so as to avoid production and treatment, The effect of mild reaction conditions and simple product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a 500ml reaction flask equipped with a thermometer and mechanical stirring, add 8.89g of methyl acetate, add 41.46g of potassium carbonate at a molar ratio of 1:2.5, keep stirring at 10-30°C, and add 2.71g of 1- Butyl-3-methylimidazolium tetrafluoroborate, add 24.80g of 1,2-dibromoethane according to the molar ratio of 1:1.1, keep stirring at 25°C for 7h, separate and obtain 3.60g of methyl cyclopropanate, and produce The rate is 30%.

Embodiment 2

[0023] Add 300mL of N,N-dimethylformamide to a 500ml reaction bottle equipped with a thermometer and mechanical stirring, add 8.89g of methyl acetate, add 41.46g of potassium carbonate at a molar ratio of 1:2.5, stir evenly, according to 1:1.1 24.80 g of 1,2-dibromoethane was added in a molar ratio, and stirred at 25° C. for 7 h to obtain 7.57 g of methyl cyclopropanecarboxylate with a yield of 63%.

Embodiment 3

[0025] Add 300mL of N,N-dimethylformamide to a 500ml reaction flask equipped with a thermometer and mechanical stirring, add 8.89g of methyl acetate, add 41.46g of potassium carbonate at a molar ratio of 1:2.5, and add it at a molar ratio of 1:0.1 2.71g 1-butyl-3-methylimidazolium tetrafluoroborate, stir evenly, add 24.80g 1,2-dibromoethane according to the molar ratio of 1:1.1, keep stirring at 25°C for 7h, separate and obtain cyclopropanecarboxylic acid Methyl ester 11.16g, yield 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com