Preparation method of water dispersible epoxy resin

An epoxy resin, dispersion-type technology, applied in the field of epoxy resin, can solve the problems of difficulty in obtaining non-ionic active epoxy resin emulsifier, limited effect of phase inversion emulsified solid epoxy resin, etc., to achieve good water dispersion performance, The effect of stable storage and easy availability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

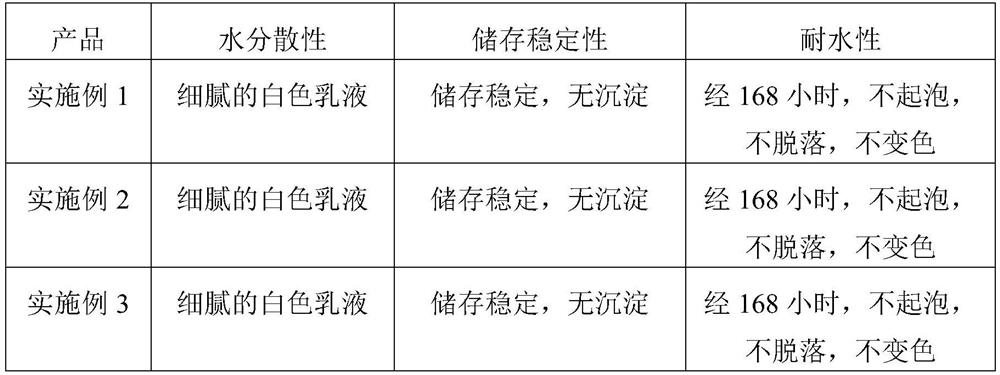

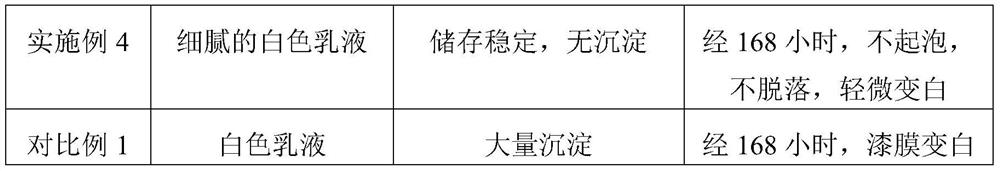

Examples

Embodiment 1

[0026] S1. Add 2229.25 kg of toluene diisocyanate and 200 kg of isomeric grade xylene to the dry reactor, keep stirring and feed nitrogen, and heat to 85 °C; mix 1000 kg of E-20 type epoxy resin with 250 Kilograms of ethyl acetate were mixed evenly and dropped into the reactor at a constant speed to react with toluene diisocyanate. The dropping time was 170 minutes, the reaction time was 6.0 hours, and the reaction temperature was 85-90°C to obtain a prepolymer;

[0027] Among them, the molar ratio of isocyanate groups in toluene diisocyanate to hydroxyl groups in E-20 epoxy resin is 8:1.

[0028] S2. The resulting prepolymer is removed by a two-stage thin-film evaporator to remove excess free toluene diisocyanate monomer until the free toluene diisocyanate in the detected prepolymer reaction solution is less than 0.5wt of the total amount of materials in the reaction system %, intermediate product is obtained;

[0029] S3. Under nitrogen protection, 1120 kg of polyethylene g...

Embodiment 2

[0032] S1. Add 2006.32 kg of toluene diisocyanate and 190 kg of isomeric grade xylene in the dry reactor, keep stirring and feed nitrogen, and heat to 85 °C; mix 800 kg of E-20 type epoxy resin with 200 kg Kilograms of butyl acetate are mixed evenly and dropped into the reactor at a constant speed to react with toluene diisocyanate. The dropping time is 150 minutes, the reaction time is 6.5 hours, and the reaction temperature is 85-90°C to obtain a prepolymer;

[0033] Among them, the molar ratio of isocyanate groups in toluene diisocyanate to hydroxyl groups in E-20 epoxy resin is 9:1.

[0034] S2. The resulting prepolymer is removed by a two-stage thin-film evaporator to remove excess free toluene diisocyanate monomer until the free toluene diisocyanate in the detected prepolymer reaction solution is less than 0.5wt of the total amount of materials in the reaction system %, intermediate product is obtained;

[0035] S3. Under nitrogen protection, 896 kg of polyethylene glyc...

Embodiment 3

[0038] S1. Add 2507.90 kg of toluene diisocyanate and 250 kg of isomeric grade xylene to the dry reactor, keep stirring and feed nitrogen, and heat to 85 °C; mix 900 kg of E-20 type epoxy resin with 230 Kg of isomeric grade toluene and 230 kg of butyl acetate are mixed evenly and then dropped into the reactor at a constant speed to react with toluene diisocyanate. The dropping time is 180min, the reaction time is 7.0h, and the reaction temperature is 85-90°C to obtain prepolymerized body;

[0039] Among them, the molar ratio of isocyanate groups in toluene diisocyanate to hydroxyl groups in E-20 epoxy resin is 10:1.

[0040] S2. the obtained prepolymer adopts two-stage thin-film evaporator to remove excess free toluene diisocyanate monomer until the free toluene diisocyanate in the detected prepolymer reaction solution is less than 0.5wt% of the total raw material, and intermediate product;

[0041] S3. Under nitrogen protection, 1008 kg of polyethylene glycol monomethyl ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com