Two-dimensional Ni-Ir porous nanosheet and preparation method and application thereof

A nanosheet, ni-ir technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems that it is difficult to obtain high-purity hydrogen, hinder large-scale commercial application, limit the large-scale application of hydrogen energy, and achieve excellent The effect of electrocatalytic activity, structural stability, and many active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

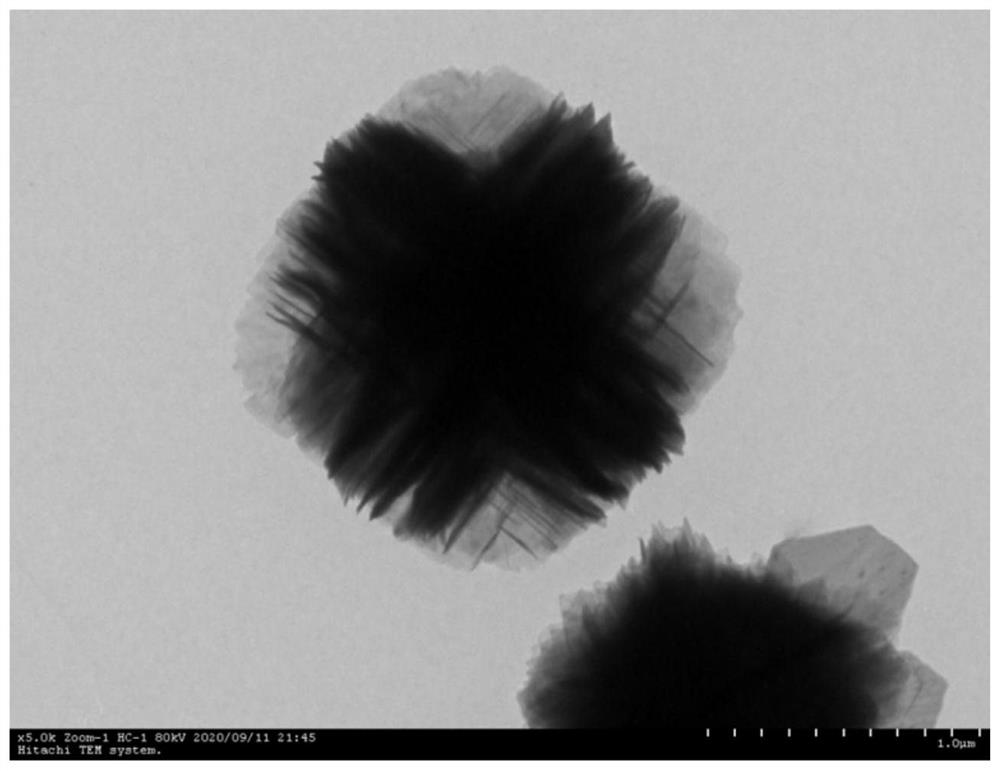

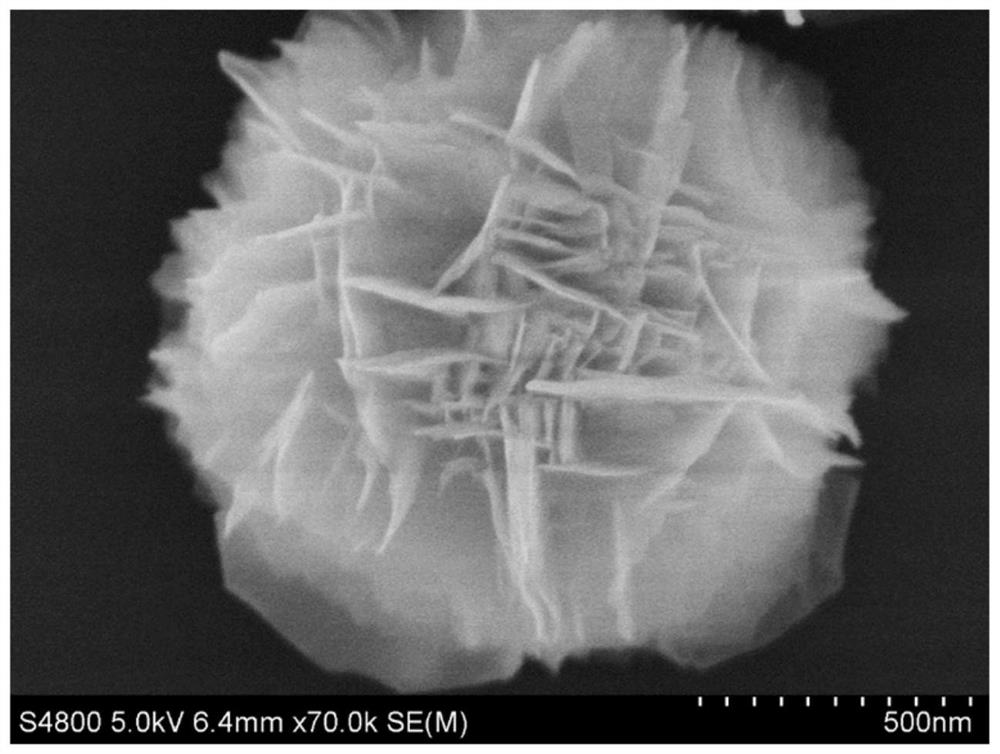

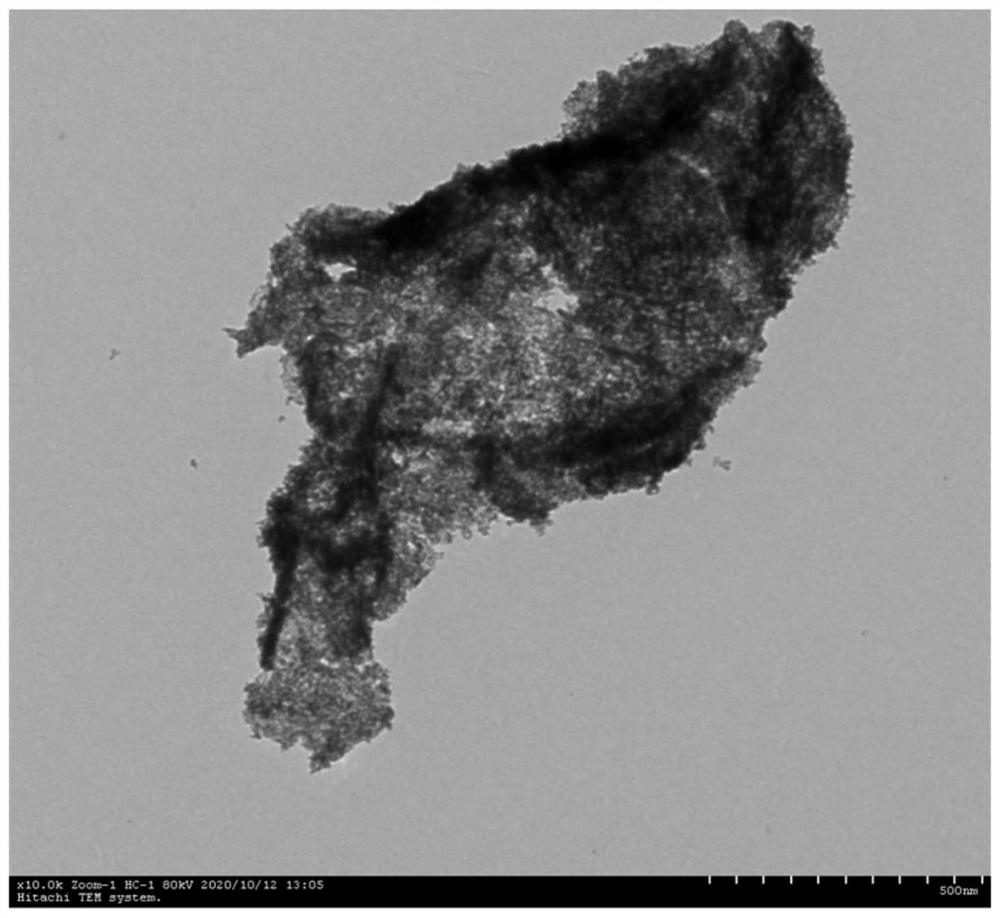

[0042] A preparation method of two-dimensional Ni-Ir porous nanosheets, comprising the following steps:

[0043] 1) Preparation of Hoffman-type complex precursors with two-dimensional layered structure

[0044] Use nickel potassium cyanide and iridium chloride as precursors, heat in an oil bath at 70°C, and keep the reaction at this temperature for 30 minutes. After the reaction system is centrifuged, the solid is washed 3 times with water to obtain a two-dimensional layered structure. The precursor of the Hoffman type complex;

[0045] 2) Preparation of two-dimensional Ni-Ir porous nanosheets

[0046] The dried two-dimensional layered Hoffman-type complex precursor was placed in a tube furnace, and the temperature was programmed to rise to 250 °C for calcination and oxidation for 2 h; after cooling to room temperature, the obtained material was loaded on carbon cloth and passed through a specific Two-dimensional Ni-Ir porous nanosheets were obtained by reduction under the e...

Embodiment 2

[0049] A preparation method of two-dimensional Ni-Ir porous nanosheets, comprising the following steps:

[0050] 1) Preparation of Hoffman-type complex precursors with two-dimensional layered structure

[0051] Use nickel potassium cyanide and iridium chloride as precursors, heat in an oil bath at 80°C, and keep the reaction at this temperature for 30 minutes. After the reaction system is centrifuged, the solid is washed several times with water to obtain a two-dimensional layered structure. The precursor of the Hoffman type complex;

[0052] 2) Preparation of two-dimensional Ni-Ir porous nanosheets

[0053] The dried two-dimensional layered Hoffman-type complex precursor was placed in a tube furnace, and the temperature was programmed to rise to 250 °C for calcination and oxidation for 2 h; after cooling to room temperature, the obtained material was loaded on carbon cloth and passed through a specific Two-dimensional Ni-Ir porous nanosheets were obtained by reduction under...

Embodiment 3

[0056] A preparation method of two-dimensional Ni-Ir porous nanosheets, comprising the following steps:

[0057] 1) Preparation of Hoffman-type complex precursors with two-dimensional layered structure

[0058] Use nickel potassium cyanide and iridium chloride as precursors, heat the oil bath at 90°C, and keep the reaction at this temperature for 30 minutes. After the reaction system is centrifuged, the solid is washed several times with water to obtain a two-dimensional layered structure. The precursor of the Hoffman type complex;

[0059] 2) Preparation of two-dimensional Ni-Ir porous nanosheets

[0060] The dried two-dimensional layered Hoffman-type complex precursor was placed in a tube furnace, and the temperature was programmed to rise to 250 °C for calcination and oxidation for 2 h; after cooling to room temperature, the obtained material was supported on carbon cloth and passed through Two-dimensional Ni-Ir porous nanosheets were obtained by reduction under a specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com