LED power supply

A technology of LED power supply and electrical connection, which is applied in the direction of circuit devices, printed circuits, electrical components, etc., and can solve the problems of large difference between working state and working frequency, increased cost, and reduced electromagnetic compatibility performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

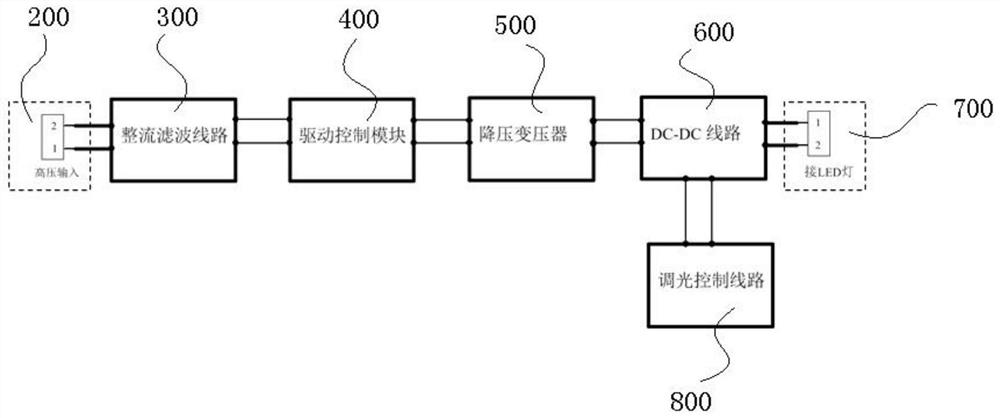

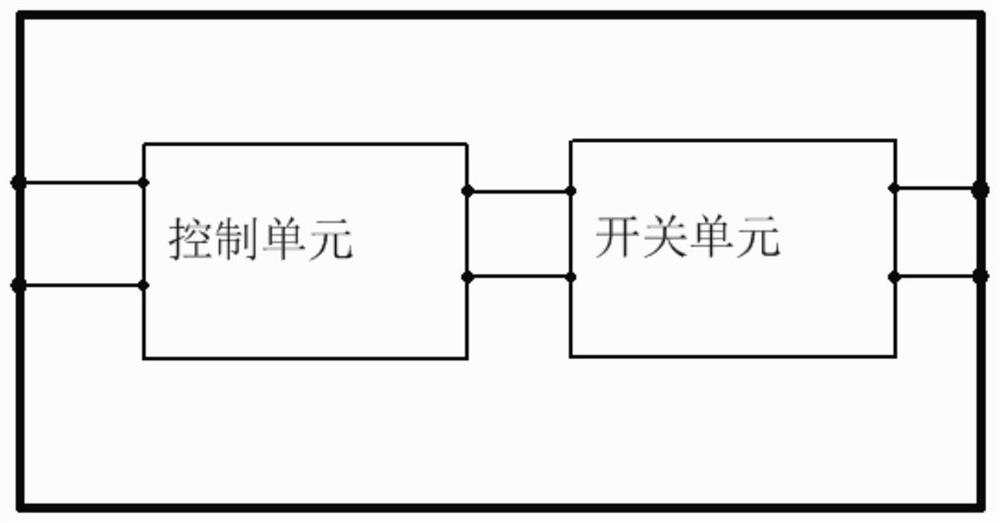

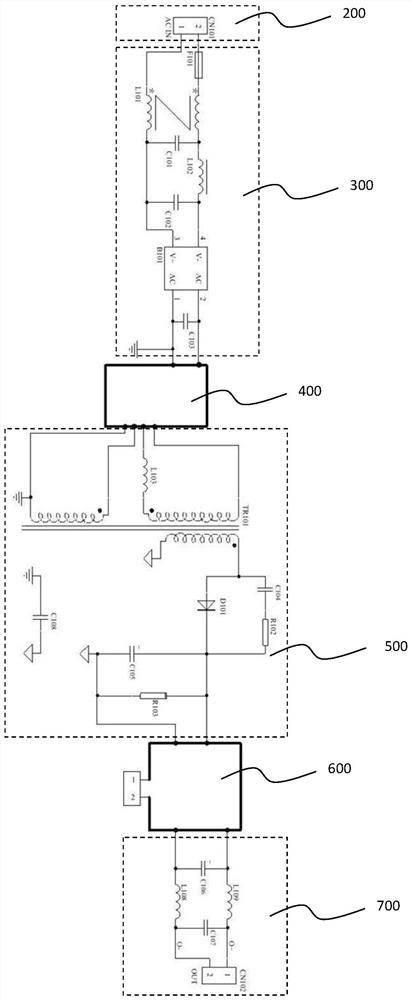

[0030] Such as Figure 1-7 As shown, the LED power supply of this embodiment includes a circuit board assembly 100, and the circuit board assembly 100 is provided with a high voltage input terminal 200, a rectification and filtering circuit 300, a drive control module 400, a step-down transformer 500, a DC- DC line 600 and LED connection terminal 700 . The power supply of the present invention uses a printed circuit board to realize the electrical connection of the electronic components of each module and circuit. How to arrange the above-mentioned modules and circuits on the circuit board is a prior art, and will not be described in detail.

[0031] The LED power supply in the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com