Preparation method of bean curd acid pulp coagulant

A technology of bean curd yogurt and coagulant, which is applied in the direction of food ingredients as a curing agent, dairy products, functions of food ingredients, etc., can solve the problems of few functional ingredients, inconvenient transportation and use, poor preservation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

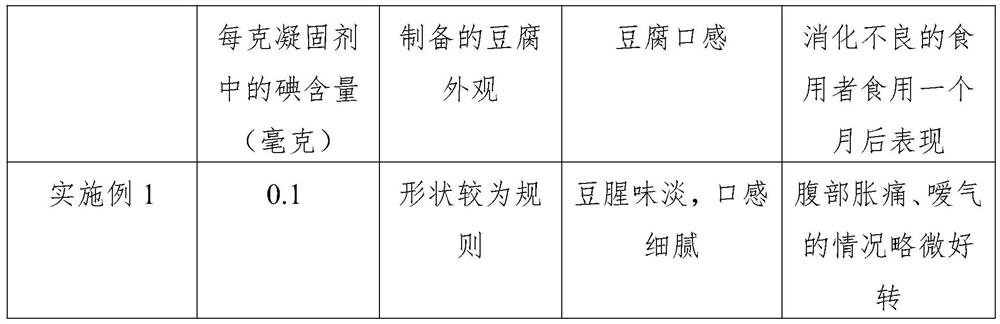

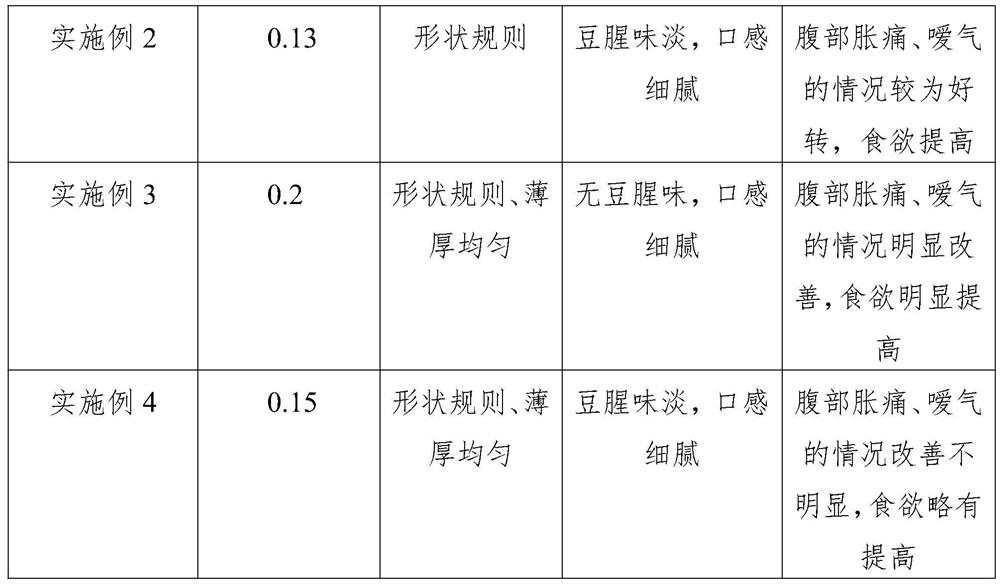

Embodiment 1

[0033] The invention provides a coagulant for bean curd yogurt. The raw materials used (by weight) include 60-80 parts of millet, 1-4 parts of citric acid, 1-4 parts of malic acid, 1-3 parts of chymotrypsin, 1-3 parts of transglutaminase, 2-5 parts of Chinese torreya, 1-3 parts of gorgon, 2-8 parts of herb, 2-10 parts of kelp, the auxiliary materials used (by weight) include 5-10 parts of lactic acid bacteria share.

[0034] And specifically in this embodiment: the raw materials used (by weight) include 60 parts of millet, 1 part of citric acid, 1 part of malic acid, 1 part of chymotrypsin, 1 part of transglutaminase, 2 parts of Chinese torreya, 1 part of Gorgon, 2 parts of Atractylodes atractylodes, 2 parts of kelp, and the auxiliary materials used (by weight) include 5 parts of lactic acid bacteria.

[0035] The present invention also includes the preparation method of this bean curd acid slurry coagulant, and concrete steps are as follows:

[0036] Step 1: Wash the millet...

Embodiment 2

[0043]The invention provides a coagulant for bean curd yogurt. The raw materials used (by weight) include 60-80 parts of millet, 1-4 parts of citric acid, 1-4 parts of malic acid, 1-3 parts of chymotrypsin, 1-3 parts of transglutaminase, 2-5 parts of Chinese torreya, 1-3 parts of gorgon, 2-8 parts of herb, 2-10 parts of kelp, the auxiliary materials used (by weight) include 5-10 parts of lactic acid bacteria share.

[0044] And specifically in this embodiment: the raw materials used (by weight) include 70 parts of millet, 2 parts of citric acid, 2 parts of malic acid, 1.5 parts of chymotrypsin, 1.5 parts of transglutaminase, 3 parts of torreya, 2 parts of gorgon, 4 parts of herb, 5 parts of kelp, and the auxiliary materials used (by weight) include 6 parts of lactic acid bacteria.

[0045] The present invention also includes the preparation method of this bean curd acid slurry coagulant, and concrete steps are as follows:

[0046] Step 1: Wash the millet, soak for 3.5 hours,...

Embodiment 3

[0053] The invention provides a coagulant for bean curd yogurt. The raw materials used (by weight) include 60-80 parts of millet, 1-4 parts of citric acid, 1-4 parts of malic acid, 1-3 parts of chymotrypsin, 1-3 parts of transglutaminase, 2-5 parts of Chinese torreya, 1-3 parts of gorgon, 2-8 parts of herb, 2-10 parts of kelp, the auxiliary materials used (by weight) include 5-10 parts of lactic acid bacteria share.

[0054] And specifically in this embodiment: the raw materials used (by weight) include 75 parts of millet, 3 parts of citric acid, 3 parts of malic acid, 2.5 parts of chymotrypsin, 2.5 parts of transglutaminase, 4 parts of torreya, 2.5 parts of gorgon, 6 parts of herb, 8 parts of kelp, and the auxiliary materials used (by weight) include 8 parts of lactic acid bacteria.

[0055] The present invention also includes the preparation method of this bean curd acid slurry coagulant, and concrete steps are as follows:

[0056] Step 1: Wash the millet, soak it for 4 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com