Remediation method for organic matter-heavy metal combined polluted soil

A technology of compound pollution and remediation method, which is applied in the field of remediation of organic matter-heavy metal compound polluted soil, and can solve problems such as long remediation period, secondary pollution of soil, poor remediation adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

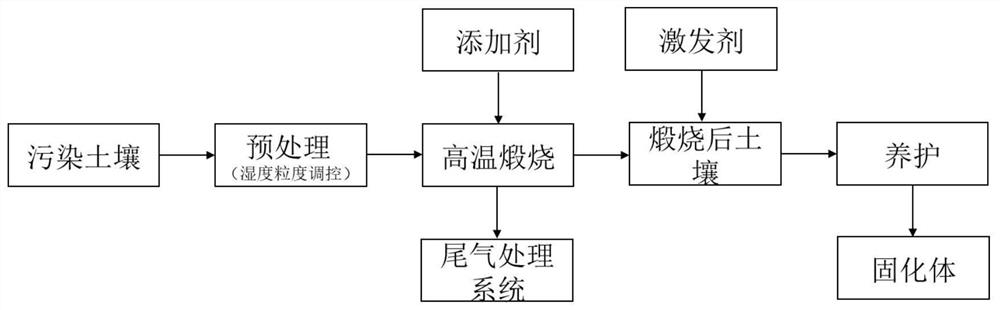

[0022] Such as figure 1 As shown, the composite contaminated soil containing 9000mg / kg total petroleum hydrocarbons and 500mg / kg nickel was dried in an oven at 110°C, then ground and crushed to below 200 mesh, kaolin and soil were mixed evenly, and the mass ratio was 1:1 , and then calcined at a high temperature of 700 ° C for 3 hours to obtain a calcined soil mixture. The organic pollutant detection of this material shows that all harmful substances have been purified. The flue gas generated during the calcination process is collected and purified before being discharged.

[0023] Then mix and stir the calcined soil mixture and alkali activator (50wt% sodium silicate solution) according to the mass ratio of 1:0.7, put the slurry into a cylindrical mold with a diameter of 50mm and a height of 100mm, and discharge the slurry through vibration Bubbles in the body, sealed and cured at room temperature for 24 hours, then removed from the mold and placed in a curing box with a hum...

Embodiment 2

[0025] Such as figure 1 As shown, the composite contaminated soil containing 60mg / kg PAHs and 4047mg / kg cadmium was dried in an oven at 110°C, then ground and crushed to below 200 mesh, and the coal gangue powder was mixed with the soil evenly, with a mass ratio of 1 : 4, then calcined at a high temperature of 750°C for 4h to obtain a calcined soil mixture, and the material was tested for organic pollutants, and the results showed that the harmful substances had all been purified. The flue gas generated during the calcination process is collected and purified before being discharged.

[0026] Then mix and stir the calcined soil mixture and the alkali activator (50wt% sodium silicate solution) according to the mass ratio of 1:0.8, put the slurry into a cylindrical mold with a diameter of 50mm and a height of 100mm, and discharge it from the slurry after shaking Bubbles, sealed and cured at room temperature for 24 hours, then removed from the mold and placed in a curing box wit...

Embodiment 3

[0028] Such as figure 1 As shown, the composite polluted soil containing 90mg / kg pyrene, 3234mg / kg lead, 4205mg / kg copper and 45mg / kg cadmium was dried in an oven at 110°C, then ground and crushed to below 200 mesh, and a certain kaolin-rich The tailings and soil were mixed evenly, with a mass ratio of 1:1.2, and then calcined at 600°C for 6 hours to obtain a calcined soil mixture. The organic pollutants were tested for this material, and the results showed that all harmful substances had been purified. The flue gas generated during the calcination process is collected and purified before being discharged.

[0029] Then mix and stir the calcined soil mixture and alkali activator (20wt% potassium silicate solution) according to the mass ratio of 1:0.6, put the slurry into a cylindrical mold with a diameter of 50mm and a height of 100mm, and discharge it out of the slurry after shaking Bubbles, sealed and cured at room temperature for 24 hours, then demoulded and placed in a cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com