Combined type particle recycling device

A technology of recycling device and granular material, applied in abrasive feeding device, used abrasive processing device, abrasive and other directions, can solve the problem of high infrastructure cost, high equipment failure rate, inflexible location of sand suction pipeline, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

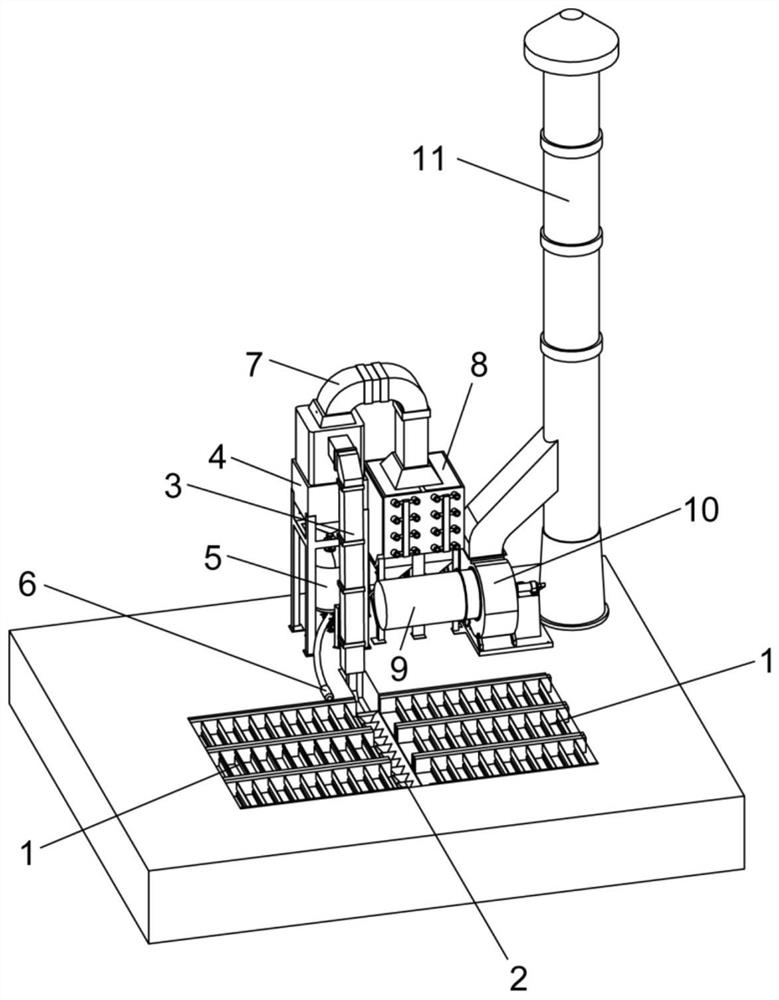

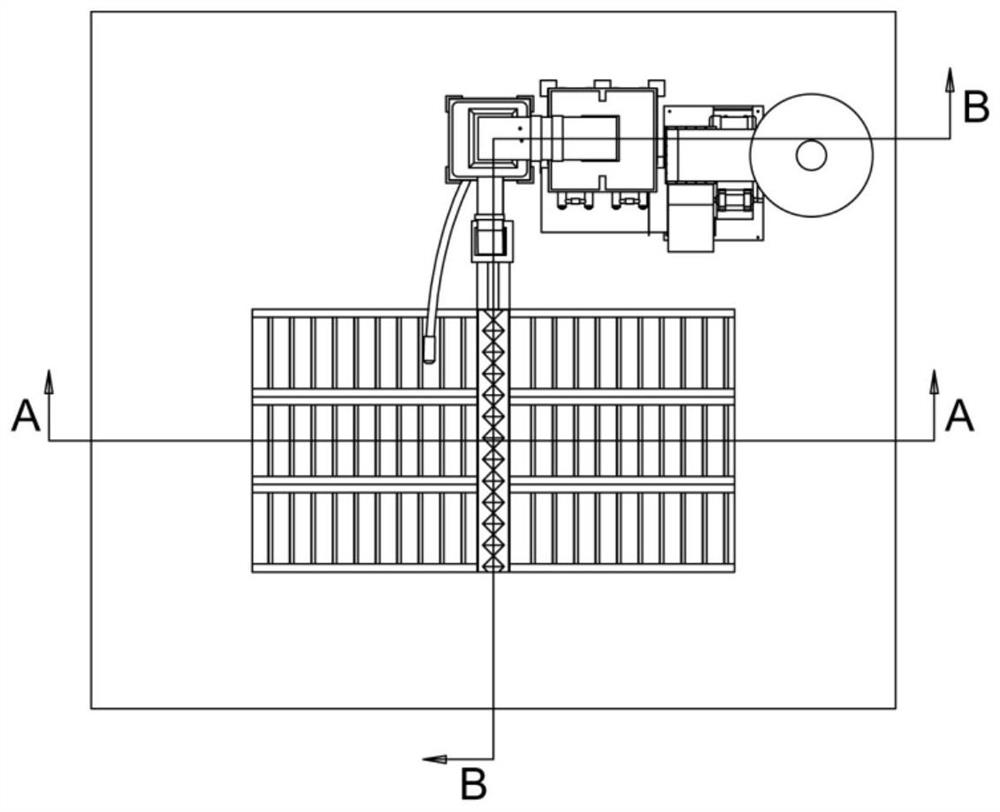

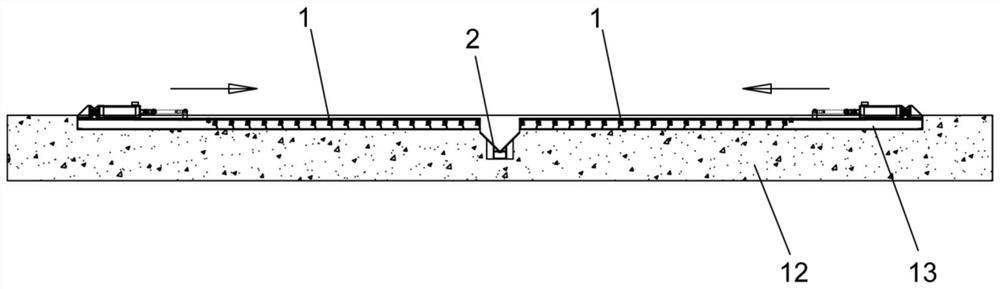

[0031] Such as Figure 1 to Figure 4 As shown, a composite granular material recovery device according to the present invention includes a particulate matter and powder material conveying equipment 1, a particulate matter collecting device 2, a conveying pipeline 3, a dust separator 4, a sandblasting tank 5, a spray gun 6, a suction Dust pipe 7, dust remover 8, dust removal pipe 9, centrifugal fan 10 and discharge pipe 11, the two sides of the particle collection device 2 are respectively provided with particle and powder conveying equipment 1, and the particles and powder on both sides of the particle collection device 2 The conveying equipment 1 can move towards the particle collection device 2 under the drive of the driving device. The discharge port of the particle collection device 2 is connected to the feed port of the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com