Spray pipe expansion section and forming method thereof

A molding method and expansion section technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of high equipment requirements and high cost, and achieve the effect of low equipment requirements, low cost, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

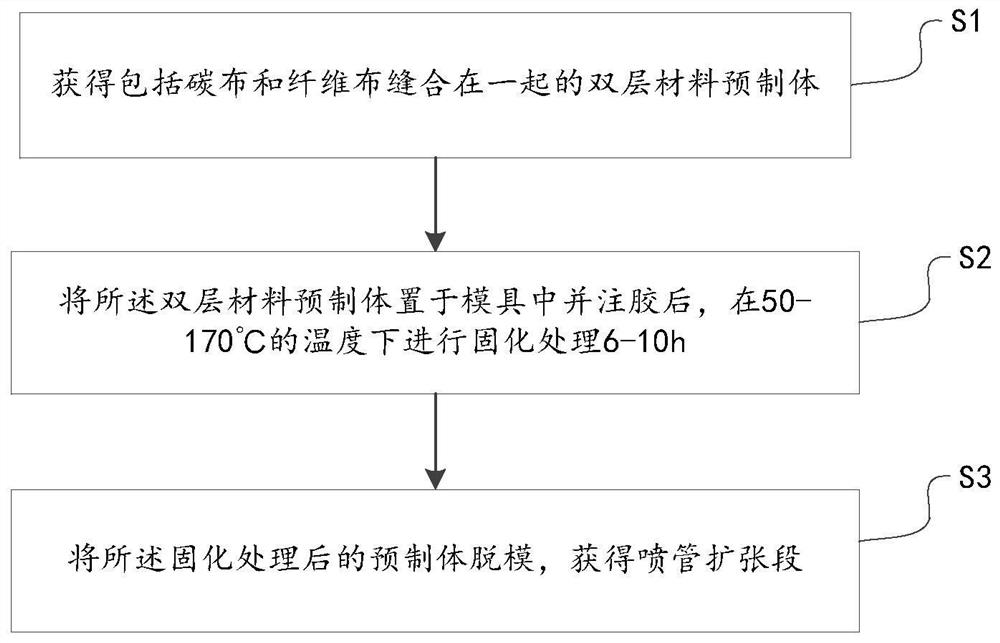

Method used

Image

Examples

Embodiment approach

[0042] As an implementation of the embodiments of the present invention, the obtaining includes a double-layer material prefabricated body sewn together by carbon cloth and fiber cloth, including:

[0043] Lay the carbon cloth layer by layer along the surface to obtain the inner layer;

[0044] Coating the fiber cloth outside the inner layer, and sewing the inner layer and the fiber cloth covered by the inner layer together with a fiber suture thread to obtain a transition layer;

[0045] Wrap the fiber cloth outside the transition layer to obtain the connecting layer;

[0046] Cover the fiber cloth outside the connecting layer, and sew the transition layer, the connecting layer and the fiber cloth wrapped outside the connecting layer together with a fiber suture thread, and perform pretreatment to obtain a carbon cloth and fiber cloth stitching Two layers of material prefabs together.

[0047]In the above covering process, a pressure of 0.1-1MPa should be applied to make th...

Embodiment 1

[0056] Embodiment 1 provides a nozzle expansion section and a forming method thereof, specifically as follows:

[0057] 1. Preparation of prefabricated body: Prefabricated body preparation steps: use carbon cloth and high silica cloth to lay layers on the molded surface in turn according to the design thickness requirements, and use fiber sutures to puncture and suture to form a double-layer material prefabricated body;

[0058] 2. Mold treatment steps: After cleaning the surface of the die, spray a layer of PMR release agent, and then keep it warm at 170°C for 2 hours;

[0059] 3. Preheating step of the prefabricated body: put the prefabricated body in step 1 into the oven heating equipment, and keep it warm for 2 hours at a temperature of 100°C;

[0060] 4. The initial mold assembly step: fill the sealing groove on the punch with a sealing rope, and connect it with the mold bottom plate as a whole;

[0061] 5. Prefabricated body suiting step: suit the prepared prefabricated...

Embodiment 2

[0069] Embodiment 2 provides a nozzle expansion section and a forming method thereof, specifically as follows:

[0070] 1. Preform preparation:

[0071] Inner layer laying step: Lay up (or wind) the carbon cloth tape layer by layer along the surface of the mold (material: wood), and the direction of the cloth tape laying (or winding) is consistent with the axis direction of the mold; laying (or winding) In the process, there must be a certain layer pressure (or winding tension) until the cloth layer is dense (the fiber volume fraction must meet the relevant requirements);

[0072] Stitching steps for transitional layer layup: Cover the surface of the carbon layer that meets the thickness requirements with a 2mm thick high-silica glass fiber cloth tape, and sew the inner layer and the transitional layer together with carbon fiber yarn. The stitching method: lock stitching, stitching needles Distance: 3*3;

[0073] The stitching steps of the connecting layer: cover the outer s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com