Water-soluble slurry capable of being quickly desized

A water-soluble and desizing technology, applied in the field of polyester sizing, can solve the problems of high adhesion, unsatisfactory sizing effect of polyester-cotton blended fabrics, and difficulty in desizing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

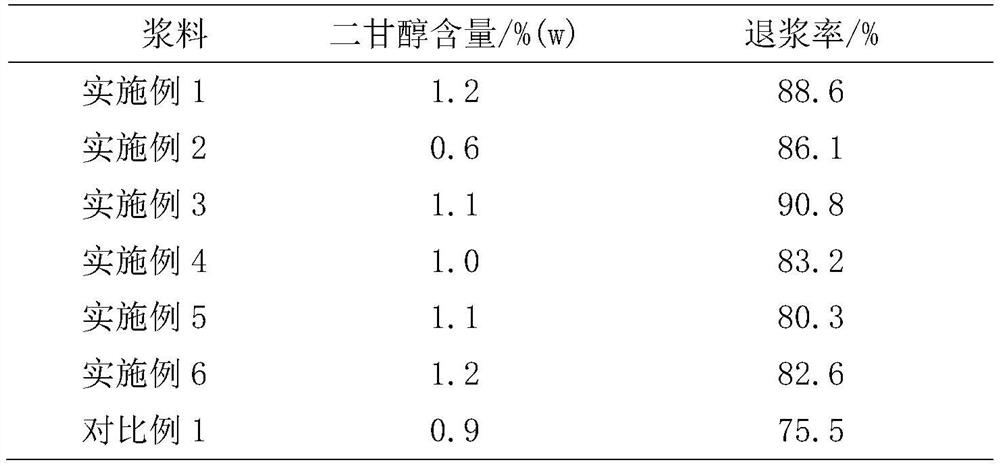

Examples

Embodiment 1

[0029] S1. Alcoholysis: Put 100 parts of recycled polyester and 45 parts of ethylene glycol into the esterification kettle at room temperature and pressure and mix for 20-40 minutes, then raise the temperature to 220°C for pre-alcoholysis for 30-60 minutes;

[0030] S2, beating: 10 parts of sodium pentasulfonate isophthalate, 5.5 parts of isophthalic acid, zinc acetate, 8 parts of stearic acid, 5 parts of dimethylol butyric acid, 6 parts of polyethylene glycol 600, hexyl 1 part of diacid, 0.5 part of anti-ether agent and the alcoholysis solution in step S1 were beaten and mixed for 10 minutes in an esterification kettle;

[0031] S3. Esterification: Control the temperature in the esterification kettle at 260° C., esterify for 2 hours to generate ethylene terephthalate, and add 5 parts of diethylene glycol after 2 hours of esterification;

[0032] S4. Filtration: the temperature of the filter is raised to 250°C, and the esterification liquid in the esterification tank is filter...

Embodiment 2

[0037] S1. Alcoholysis: put 100 parts of recycled polyester and 35 parts of ethylene glycol into the esterification tank at room temperature and pressure and mix for 40 minutes, then raise the temperature to 220°C for pre-alcoholysis for 60 minutes;

[0038] S2, beating: 8 parts of sodium pentasulfonate isophthalate, 18 parts of isophthalic acid, zinc acetate, 5 parts of stearic acid, 8 parts of dimethylol butyric acid, 2 parts of ethylene glycol, 6 parts of polystyrene Ether diol 400, 1 part of polyester polyol, 0.5 part of anti-ether agent and the alcoholysis solution in step S1 were beaten and mixed in an esterification kettle for 10 minutes;

[0039] S3. Esterification: Control the temperature in the esterification kettle at 260°C, and perform esterification for 2 hours to generate ethylene terephthalate;

[0040] S4. Filtration: the temperature of the filter is raised to 270°C, and the esterification liquid in the esterification tank is filtered to remove insoluble matter...

Embodiment 3

[0045] S1. Alcoholysis: put 100 parts of recycled polyester and 40 parts of ethylene glycol into the esterification tank at room temperature and pressure and mix for 30 minutes, then raise the temperature to 230°C for pre-alcoholysis for 45 minutes;

[0046] S2, beating: 19 parts of sodium pentasulfonate isophthalate, 12 parts of isophthalic acid, zinc acetate, 6.5 parts of stearic acid, 6.5 parts of dimethylol butyric acid, 3.5 parts of polyethylene glycol 600, hexane 2 parts of diacid, 0.3 parts of anti-ether agent and the alcoholysis solution in step S1 were beaten and mixed for 15 minutes in an esterification kettle;

[0047]S3. Esterification: Control the temperature in the esterification kettle at 250°C, esterify for 2.8 hours to generate ethylene terephthalate, and add 3.5 parts of diethylene glycol after 1.5 hours of esterification;

[0048] S4. Filtration: the temperature of the filter is raised to 260°C, and the esterification liquid in the esterification tank is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com