Water-based quick-drying low-VOC alkyd coating and preparation method thereof

A kind of alkyd paint, water-based technology, applied in the direction of anti-corrosion paint, polyester paint, coating, etc., can solve the problems of emulsifier wastewater treatment, affecting the compactness of paint film, ecological environment pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

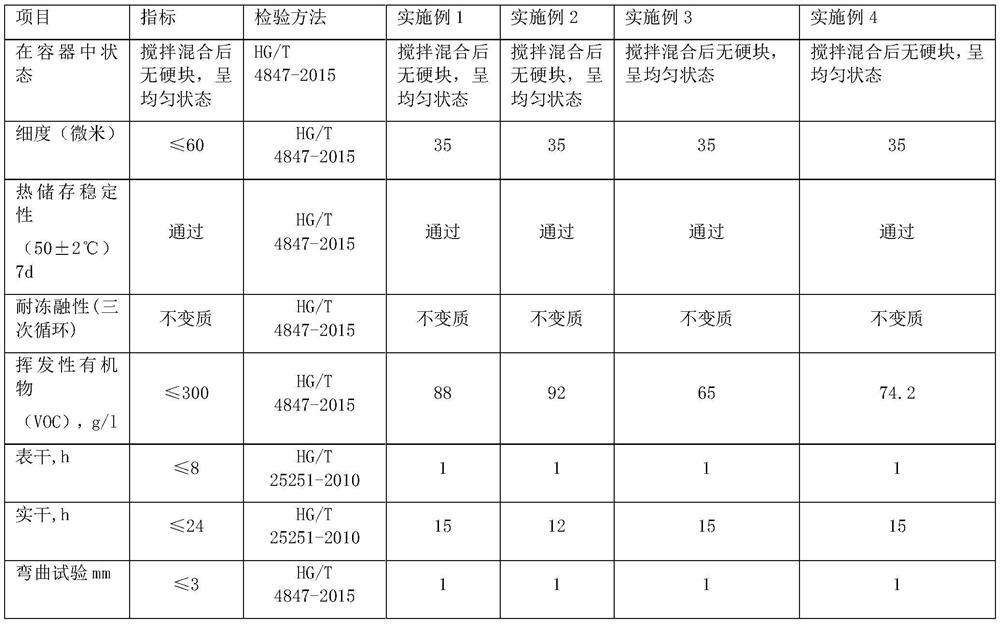

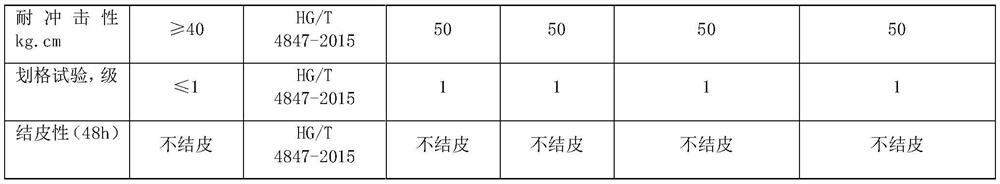

Examples

Embodiment 1

[0028] A kind of water-based quick-drying low-VOC alkyd coating of the present embodiment is prepared from the following raw materials in parts by weight:

[0029] 70 parts of alkyd resin aqueous dispersion (350Kg), 0.1 part of defoamer (0.5Kg), 0.3 part of dispersant (1.5Kg), 15 parts of pigment (75Kg), 50 parts of precipitated barium sulfate (100Kg) and 30 parts of Ionized water (150Kg), 0.5 parts of rheological agent (2.5Kg), 0.16 parts of drier (0.8Kg), 0.06 parts of anti-skinning agent (0.3Kg), 0.2 parts of anti-flash rust agent (1Kg) and 0.4 parts Anti-settling agent (2Kg);

[0030] The alkyd resin aqueous dispersion is prepared from quick-drying alkyd resin and deionized water and amine neutralizer with a mass ratio of 3.75:1, and the consumption of the amine neutralizer is the mass of quick-dry alkyd resin 4% (w / w). Wherein, the amine neutralizing agent is dimethylethanolamine.

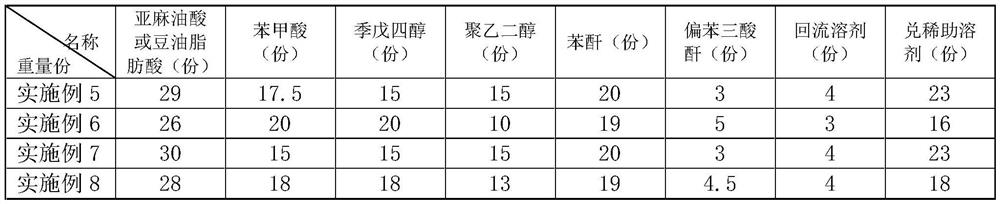

[0031] The quick-drying alkyd resin is composed of the following raw materials in parts...

Embodiment 2

[0042] A kind of water-based quick-drying low-VOC alkyd paint of the present embodiment has the following differences compared with embodiment 1:

[0043] A water-based quick-drying low-VOC alkyd coating is prepared from the following raw materials in parts by weight:

[0044] 60 parts of alkyd resin water dispersion (300Kg), 0.1 part of defoamer (0.5Kg), 0.3 part of dispersant (1.5Kg), 25 parts of pigment (125Kg), 10 parts of precipitated barium sulfate (50Kg) and 25 parts of Ionized water (125Kg), 0.5 parts of rheological agent (2.5Kg), 0.16 parts of drier (0.8Kg), 0.06 parts of anti-skinning agent (0.3Kg), 0.2 parts of anti-flash rust agent (1Kg) and 0.4 parts Anti-settling agent (2Kg);

[0045] The pigment is medium chrome yellow.

[0046] The constituents of the alkyd resin water dispersion and the quick-drying alkyd resin are the same as in Example 1.

[0047] A kind of preparation method of water-based quick-drying low VOC alkyd coating of the present embodiment, com...

Embodiment 3

[0053] A kind of water-based quick-drying low-VOC alkyd paint of the present embodiment has the following differences compared with embodiment 1:

[0054] A water-based quick-drying low-VOC alkyd coating is prepared from the following raw materials in parts by weight:

[0055] 80 parts of alkyd resin aqueous dispersion (400Kg), 0.1 part of defoamer (0.5Kg), 0.3 part of dispersant (1.5Kg), 20 parts of pigment (100Kg), 15 parts of precipitated barium sulfate (75Kg) and 48 parts of Ionized water (240Kg), 0.5 parts of rheological agent (2.5Kg), 0.16 parts of drier (0.8Kg), 0.06 parts of anti-skinning agent (0.3Kg), 0.2 parts of anti-flash rust agent (1Kg) and 0.4 parts Anti-settling agent (2Kg);

[0056] The pigment is rutile titanium dioxide.

[0057] The constituents of the alkyd resin water dispersion and the quick-drying alkyd resin are the same as in Example 1.

[0058] A kind of preparation method of water-based quick-drying low VOC alkyd coating of the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com