Method for modifying Ag-In-Zn-S quantum dots by ferrocene derivatives and application of Ag-In-Zn-S quantum dots

A ferrocene derivative, ag-in-zn-s technology, applied in chemical instruments and methods, hydrogen production, chemical/physical processes, etc., can solve problems such as low hole mobility and photocorrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of Ag-In-Zn-S quantum dot precursor:

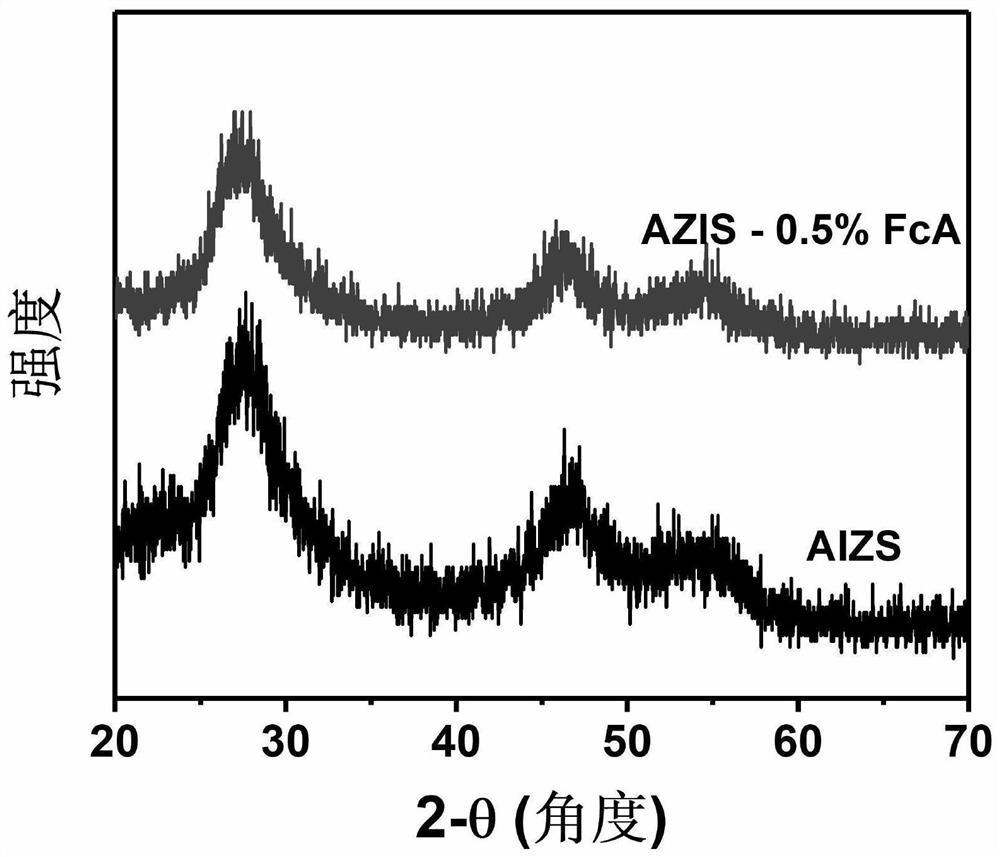

[0034] Weigh 0.17 mmol of silver nitrate, 1.7 mmol of indium nitrate, 0.85 mmol of zinc acetate dihydrate, and 5 mmol of L-cysteine, mix and dissolve in the aqueous solution, mix the above solutions and adjust the pH value of the solution to 8.5 with 1M NaOH, add thio Acetamide was ultrasonically stirred, and hydrothermally reacted in an autoclave at 110° C. for 4 hours. After the reaction was completed, it was centrifuged and washed to obtain Ag-In-Zn-S quantum dots.

[0035] (2) Preparation of Ag-In-Zn-S-FcA composite photocatalyst:

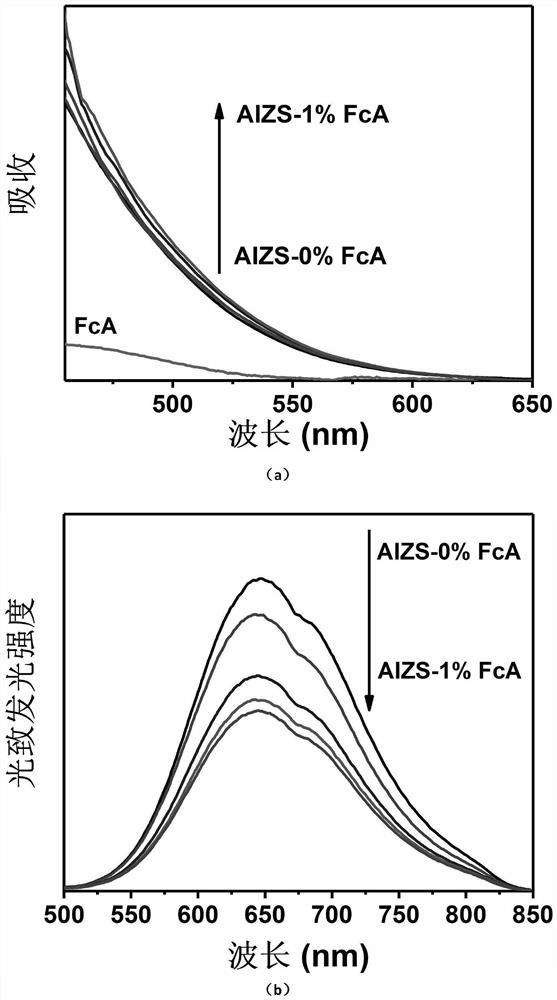

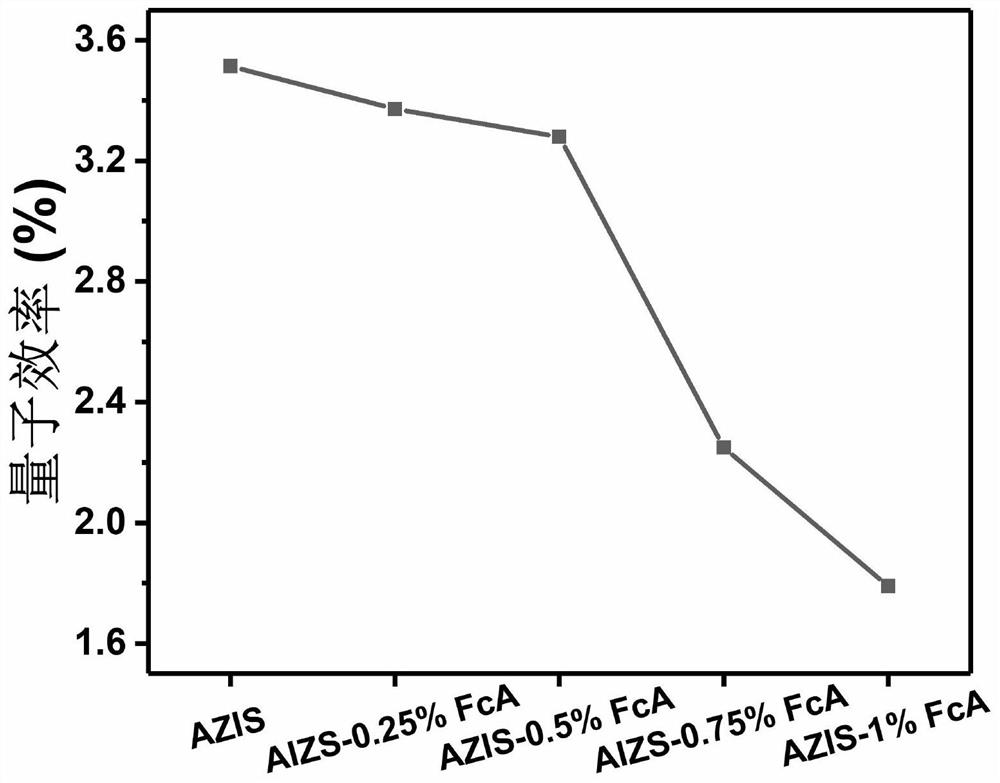

[0036] Extract 100 mg of AIZS quantum dots and mix them with 0.5 mg of ferrocenecarboxylic acid (solvent dimethyl sulfoxide, 1 mg / ml), and then hydrothermally treat them in an autoclave at 110°C for 4 hours.

[0037] Take 0.02 g of the catalyst and 0.528 g of L-ascorbic acid from the sample in (2) and add them to the photoreactor. 2After the gas in the bottle was exhausted, the cus...

Embodiment 2

[0039] (1) Preparation of Ag-In-Zn-S quantum dot precursor:

[0040] Weigh 0.34 mmol of silver nitrate, 1.7 mmol of indium nitrate, 0.85 mmol of zinc acetate dihydrate, and 5 mmol of L-cysteine, mix and dissolve in the aqueous solution, mix the above solutions and adjust the pH value of the solution to 8.5 with 1M NaOH, add thio Acetamide was ultrasonically stirred, and hydrothermally reacted in an autoclave at 110° C. for 4 hours. After the reaction was completed, it was centrifuged and washed to obtain Ag-In-Zn-S quantum dots.

[0041] (2) Preparation of Ag-In-Zn-S-FcA composite photocatalyst:

[0042] Extract 100 mg of AIZS quantum dots and mix them with 0.5 mg of ferrocenecarboxylic acid (solvent dimethyl sulfoxide, 1 mg / ml), and then hydrothermally treat them in an autoclave at 110°C for 4 hours.

[0043] Take 0.02 g of the catalyst and 0.528 g of L-ascorbic acid from the sample in (2) and add them to the photoreactor. 2 After the gas in the bottle was exhausted, the cu...

Embodiment 3

[0045] (1) Preparation of Ag-In-Zn-S quantum dot precursor:

[0046] Weigh 0.51 mmol of silver nitrate, 1.7 mmol of indium nitrate, 0.85 mmol of zinc acetate dihydrate, and 5 mmol of L-cysteine, mix and dissolve in the aqueous solution, mix the above solutions and adjust the pH value of the solution to 8.5 with 1M NaOH, add thio Acetamide was ultrasonically stirred, and hydrothermally reacted in an autoclave at 110° C. for 4 hours. After the reaction was completed, it was centrifuged and washed to obtain Ag-In-Zn-S quantum dots.

[0047] (2) Preparation of Ag-In-Zn-S-FcA composite photocatalyst:

[0048] Extract 100 mg of AIZS quantum dots and mix them with 0.5 mg of ferrocenecarboxylic acid (solvent dimethyl sulfoxide, 1 mg / ml), and then hydrothermally treat them in an autoclave at 110°C for 4 hours.

[0049] Take 0.02 g of the catalyst and 0.528 g of L-ascorbic acid from the sample in (2) and add them to the photoreactor. 2 After the gas in the bottle was exhausted, the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com