Preparation method of supported photocatalyst containing Mn0.5Cd0.5S and Au

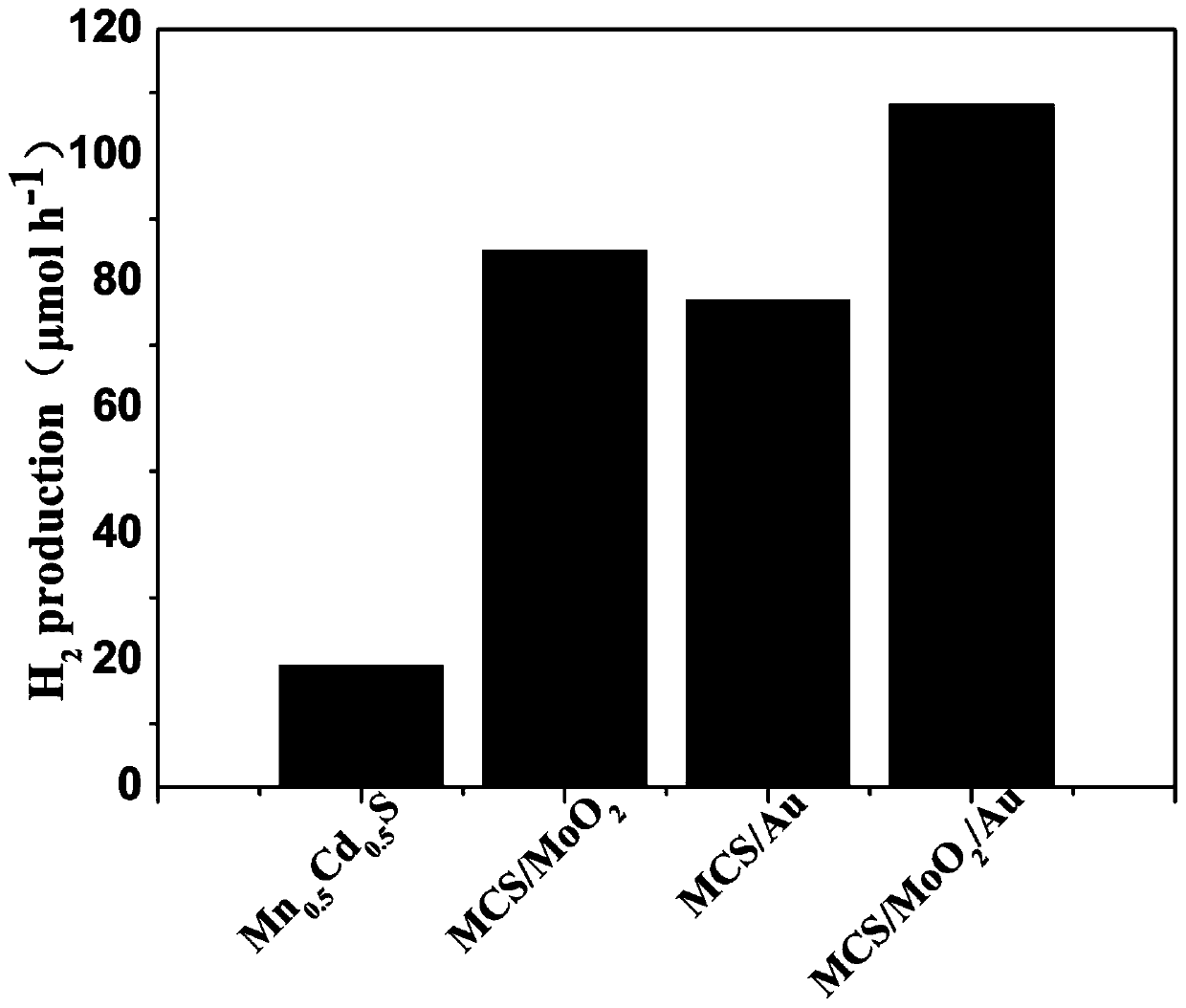

A photocatalyst and load-type technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of limited photocatalytic activity and low quantum efficiency, and achieve improved photocatalytic activity and enhanced Effects of light absorption, enhanced quantum efficiency, and hydrogen production efficiency by photo-splitting water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

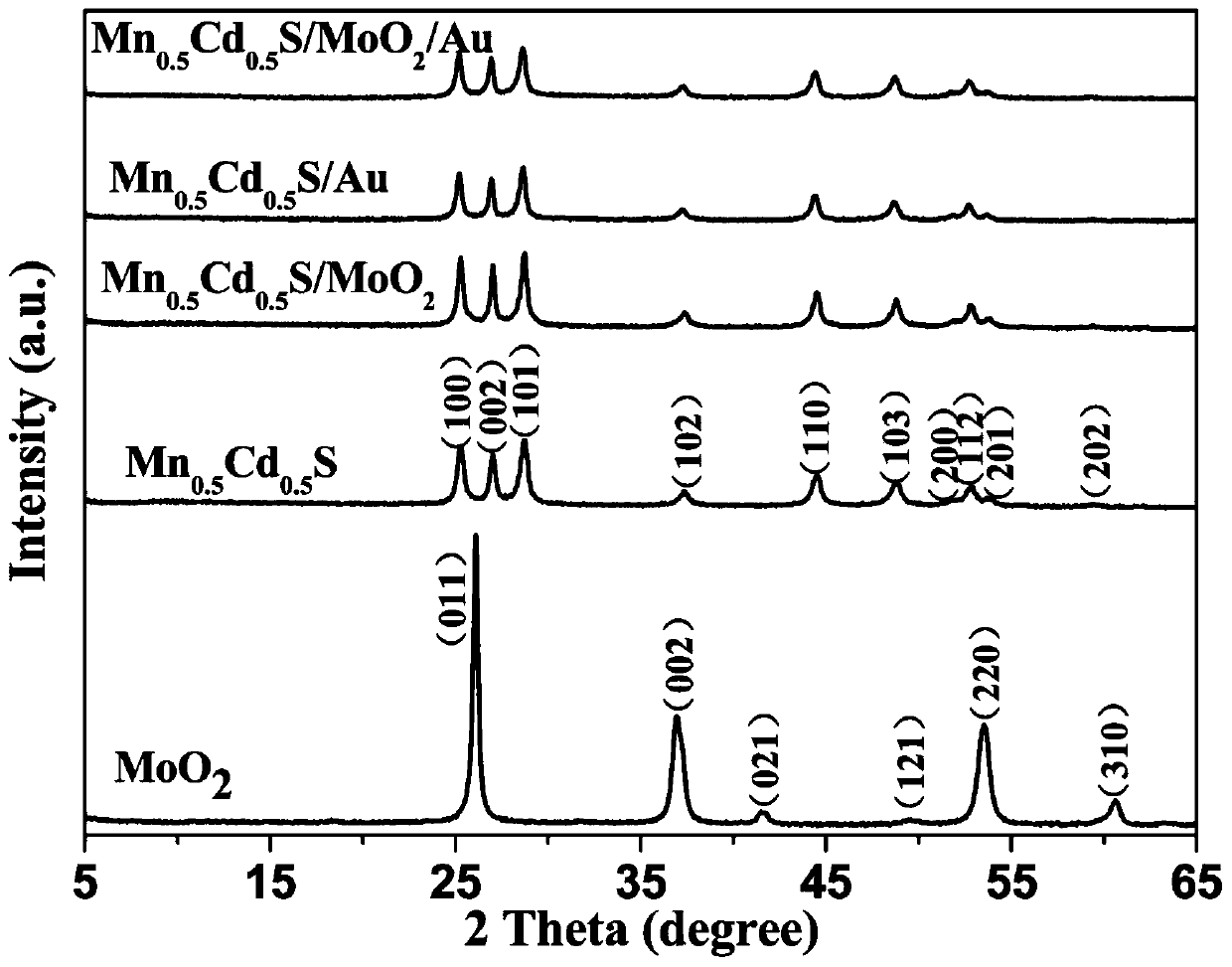

[0031] 1) MoO 2 Preparation: weigh 0.288g molybdenum trioxide and 0.095g molybdenum powder and dissolve in 40ml deionized water, then add 0.2g ammonium chloride, stir at room temperature for 2 hours, then transfer the mixed solution to a 50mL polytetrafluoroethylene kettle , hydrothermal reaction was carried out at 200°C for 15 hours, and after the reaction was completed, it was cooled to room temperature, and the obtained product was filtered and washed with deionized water and absolute ethanol, and vacuum-dried to obtain MoO 2 powder.

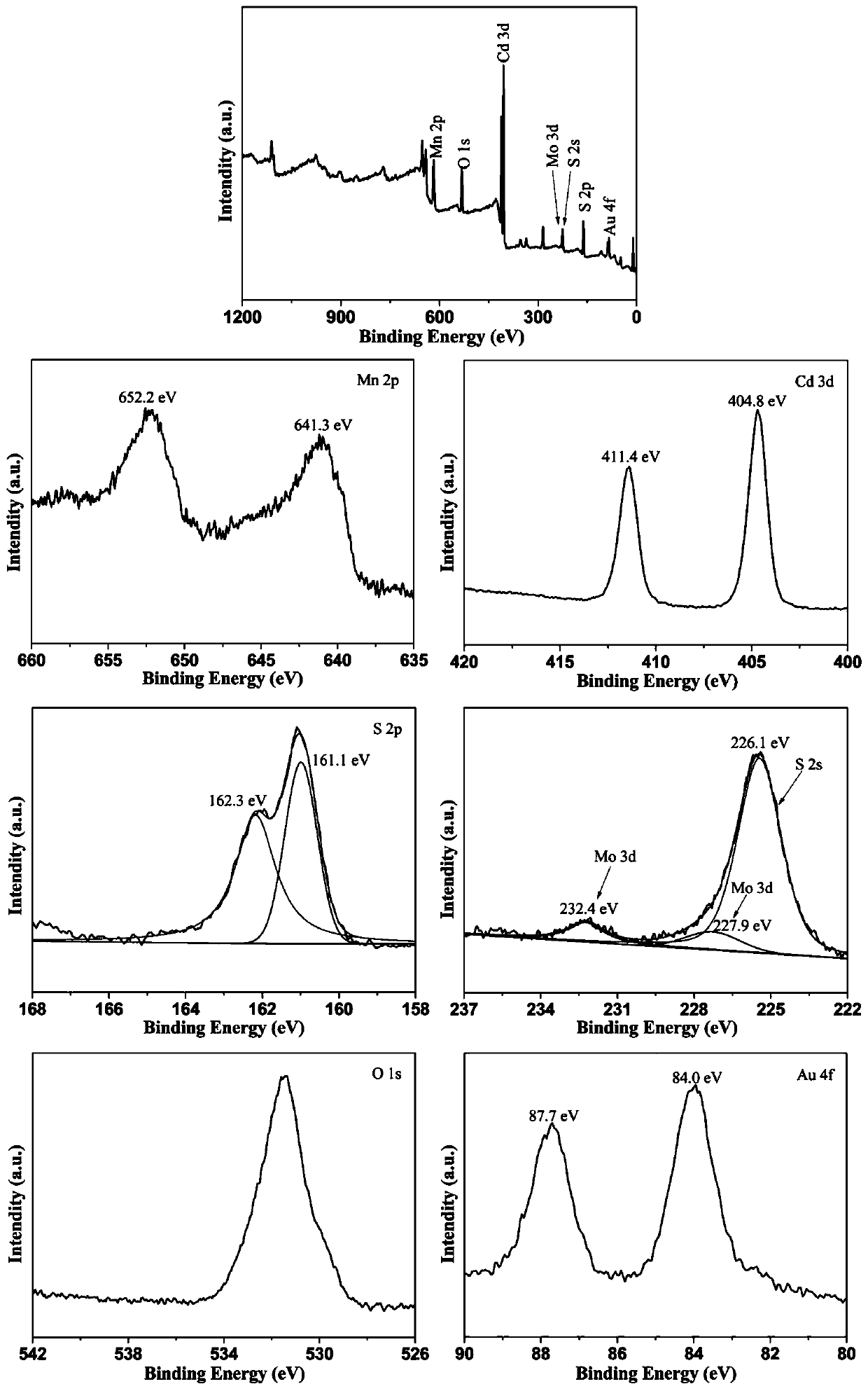

[0032] (2) Mn 0.5 Cd 0.5 S / MoO 2 Preparation of composite sample: Weigh 1.442g L-cystine and dissolve it in 40mL deionized water, then adjust the solution with 6M NaOH to make the solution pH=10.6 to form A mixed solution; weigh 0.266g cadmium acetate dihydrate and 0.245g Manganese acetate dihydrate was dissolved in 25mL deionized water to form a mixed solution of B; 0.0011gMoO obtained in step (1) was weighed 2 Disperse the powder in 10...

Embodiment 2

[0038] 1) MoO 2 Preparation: weigh 0.144g molybdenum trioxide and 0.0475g molybdenum powder and dissolve in 40mL deionized water, then add 0.1g ammonium chloride, stir at room temperature for 2 hours, then transfer the mixed solution to a 50mL polytetrafluoroethylene kettle , hydrothermal reaction was carried out at 200°C for 15 hours, and after the reaction was completed, it was cooled to room temperature, and the obtained product was filtered and washed with deionized water and absolute ethanol, and vacuum-dried to obtain MoO 2 powder.

[0039] (2) Mn 0.5 Cd 0.5 S / MoO 2 Preparation of composite sample: Weigh 2.884g L-cystine and dissolve it in 40mL deionized water, then adjust the solution with 6M NaOH to make the solution pH=10.6 to form A mixed solution; weigh 0.532g cadmium acetate dihydrate and 0.49g Manganese acetate dihydrate was dissolved in 25mL deionized water to form a mixed solution of B; 0.0069g MoO obtained in step (1) was weighed 2 Disperse the powder in 1...

Embodiment 3

[0042] 1) MoO 2 Preparation: Weigh 0.216g molybdenum trioxide and 0.0713g molybdenum powder and dissolve in 40mL deionized water, then add 0.15g ammonium chloride, stir at room temperature for 2 hours, then transfer the mixed solution to a 50mL polytetrafluoroethylene kettle , hydrothermal reaction was carried out at 200°C for 15 hours, and after the reaction was completed, it was cooled to room temperature, and the obtained product was filtered and washed with deionized water and absolute ethanol, and vacuum-dried to obtain MoO 2 powder.

[0043] (2) Mn 0.5 Cd 0.5 S / MoO 2 Preparation of composite sample: Weigh 1.0815g L-cystine and dissolve it in 40mL deionized water, then adjust the solution with 6M NaOH to make the solution pH=10.6 to form A mixed solution; weigh 0.1995g cadmium acetate dihydrate and 0.1838g Dissolve manganese acetate dihydrate in 25mL deionized water to form a mixed solution of B; weigh 0.0023gMoO obtained in step (1) 2 Disperse the powder in 10mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com