Copper-iron layered double metal hydroxide, copper-iron layered double metal hydroxide/carbon matrix composite material and preparation method and application thereof

A carbon-based composite material, layered bimetal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc. Monotonicity, low ammonia nitrogen removal efficiency, etc., to achieve the effect of low cost, significant ammonia nitrogen removal, and abundant active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

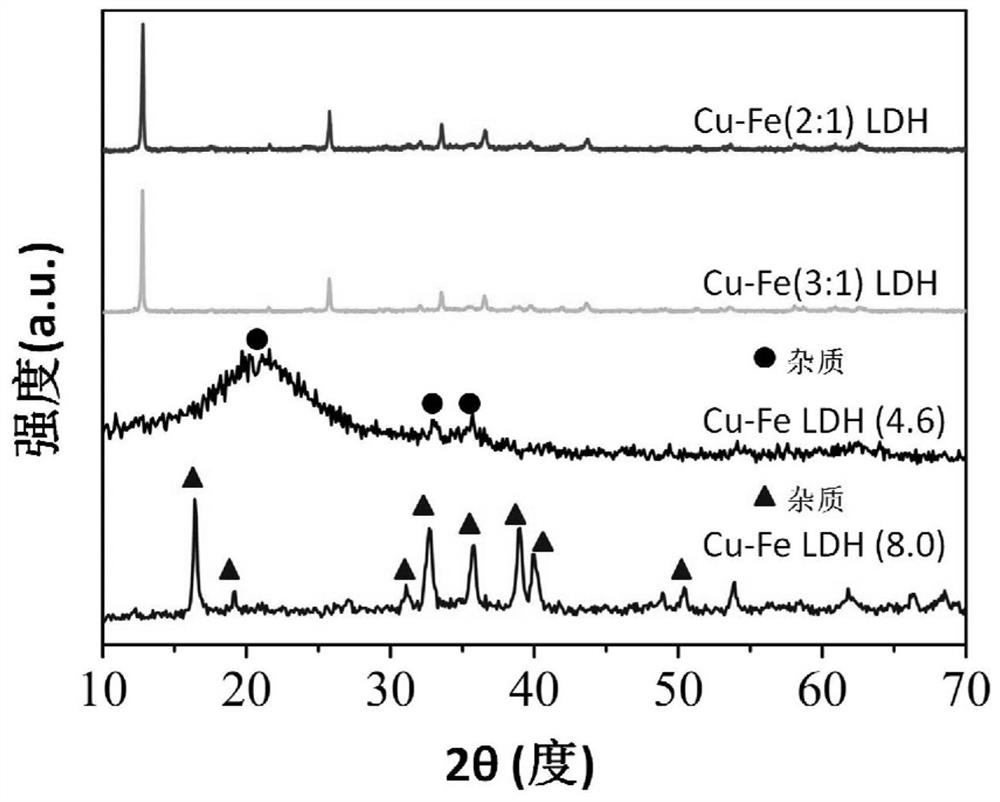

[0049] Example 1 Preparation of copper-iron layered double metal hydroxide (Cu-Fe(2:1)LDH) 0.02mol Cu(NO 3 ) 2 ·3H 2 O and 0.01mol Fe(NO 3 ) 3 ·9H 2 O was dissolved in 300ml of deionized water, then sonicated at room temperature until the metal salt was completely dissolved, and an alkaline reagent prepared with sodium hydroxide and sodium carbonate was added dropwise, wherein the concentration of sodium hydroxide was 0.5M, and the concentration of sodium carbonate was 0.02 M; slowly add an alkaline reagent to the mixed solution, keep stirring, adjust the pH to 6.7, and continue stirring for one hour; stop stirring, put the mixed solution in a 110°C oven, let it stand, and age for 5 hours; discard the aged sample The supernatant and the remaining mixture were washed with deionized water by centrifugation at least three times, and the obtained samples were placed in a 60 °C oven for 10 h, and then ground to obtain Cu-Fe (2:1) LDH samples. The XRD pattern of the obtained pr...

Embodiment 2

[0051] Example 2 Preparation of copper-iron layered double metal hydroxide (Cu-Fe(3:1)LDH) 0.0225mol Cu(NO 3 ) 2 ·3H 2 O and 0.0075mol Fe(NO 3 ) 3 9H2O was dissolved in 300ml of deionized water, then sonicated at room temperature until the metal salt was completely dissolved, and an alkaline reagent prepared with sodium hydroxide and sodium carbonate was added dropwise, wherein the sodium hydroxide concentration was 0.5M, and the sodium carbonate concentration was 0.015M; slowly add alkaline reagent to the mixed solution, keep stirring, adjust the pH to 6.7, and continue stirring for one hour; stop stirring, put the mixed solution in a 110°C oven, let it stand, and age for 5 hours; discard the aged sample The supernatant was washed with deionized water at least three times by centrifugation, and the obtained sample was dried in an oven at 60 °C for 10 h, and then ground to obtain a Cu-Fe (3:1) LDH sample. The XRD pattern of the obtained product is as follows figure 1 As s...

Embodiment 3

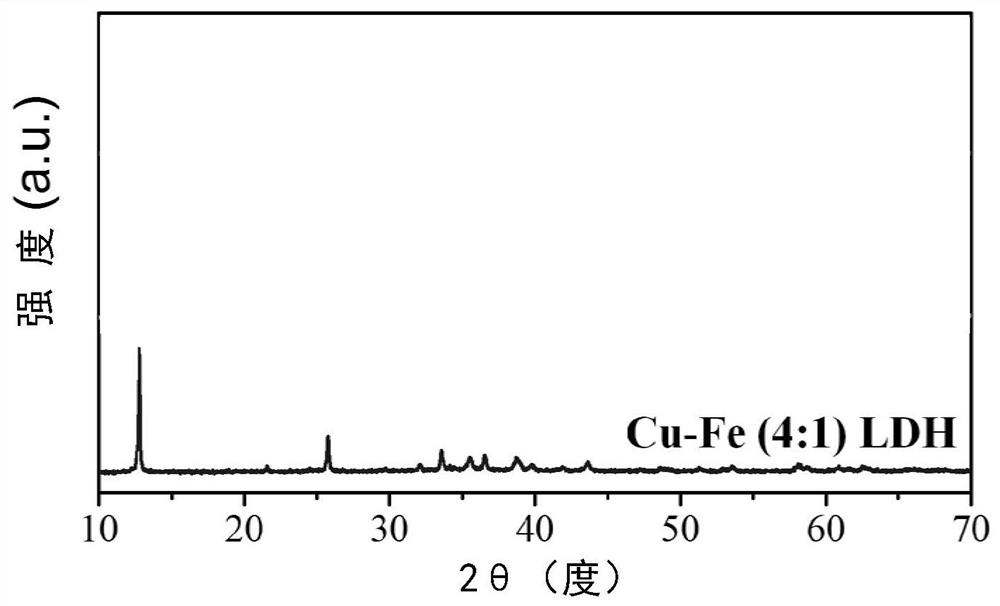

[0053] Example 3 Preparation of copper-iron layered double metal hydroxide (Cu-Fe(4:1)LDH).

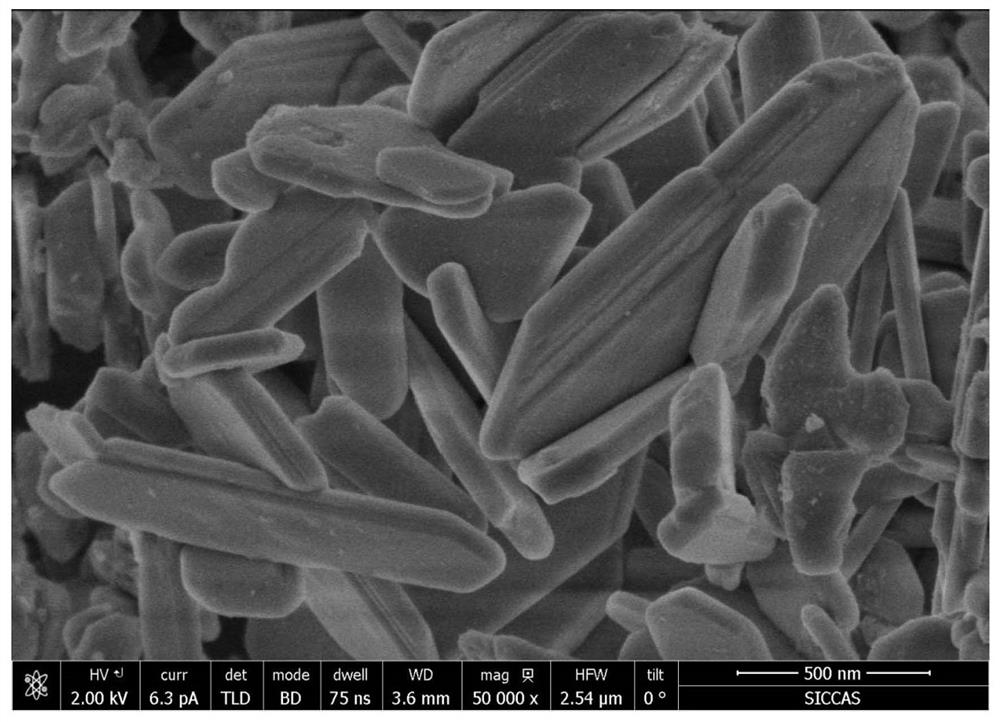

[0054] 0.024mol Cu(NO 3 ) 2 ·3H 2 O and 0.006mol Fe(NO 3 ) 3 ·9H 2 O was dissolved in 300ml of deionized water, then sonicated at room temperature until the metal salt was completely dissolved, and an alkaline reagent prepared with sodium hydroxide and sodium carbonate was added dropwise, wherein the concentration of sodium hydroxide was 0.5M, and the concentration of sodium carbonate was 0.012 M; slowly add an alkaline reagent to the mixed solution, keep stirring, adjust the pH to 6.7, and continue stirring for one hour; stop stirring, put the mixed solution in a 110°C oven, let it stand, and age for 5 hours; discard the aged sample The supernatant and the remaining mixture were centrifuged and washed with deionized water for at least three times, and the obtained samples were placed in an oven at 60 °C for 10 h, and then ground to obtain Cu-Fe (4:1) LDH samples. The scanning e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com