Carbon-doped ultrathin bismuth tungstate nanosheet photocatalytic material and preparation method thereof

A technology of ultra-thin bismuth tungstate and photocatalytic materials, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. Active sites and other issues, to achieve the effects of excellent visible light response and charge transfer ability, low recombination efficiency, and improved solar energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The synthesis process of carbon-doped ultrathin bismuth tungstate nanosheet photocatalytic material is as follows:

[0040] 1) Na 2 WO 4 , a certain amount of cetyltrimethylammonium bromide (CTAB) was dissolved in distilled water to form a uniform solution, wherein the concentration of CTAB was 0.625mg / mL; 2) Bi(NO 3 ) 3 Pour the powder into the solution obtained in step 1), and stir rapidly for more than 1 hour until the solution turns milky white, wherein the molar ratio of CTAB:W:Bi is 1:7:14, and pour the obtained solution into a 50ml polytetrafluoroethylene reaction kettle reaction at 120°C for 24 hours, the resulting precipitate was washed 3 times with water and ethanol, filtered and dried to obtain an ultra-thin bismuth tungstate nanosheet photocatalytic material; 3) the ultra-thin tungstic acid containing residual CTAB obtained in step 2) Bismuth nanosheets were placed in a tube furnace in N 2 The carbon-doped ultrathin bismuth tungstate nanosheet photocatal...

Embodiment 2

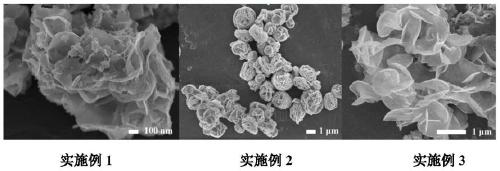

[0050] In order to examine the effect of CTAB on the morphology and structure of carbon-doped bismuth tungstate nanosheet photocatalyst materials, except for CTAB, other reaction conditions are as follows: sample addition sequence, stirring time, W:Bi ratio, reaction temperature (120°C), reaction Time (24h), heat treatment time (1h), temperature (350 ℃) etc. are all identical with embodiment 1. The results showed that when no CTAB was added, since no CTAB was inserted into Bi 2 WO 6 Between molecular layers, Bi 2 WO 6 In the hydrothermal synthesis process, thick sheets self-assemble into a spherical structure. Compared with the carbon-doped ultra-thin bismuth tungstate nanosheets in Example 1, the ultra-thin two-dimensional nanosheet structure cannot be formed, nor can it be calcined for doping modification. . When the concentration of CTAB is adjusted in the range of 0.5-0.7 mg / mL, bismuth tungstate nanosheets with ultrathin structure can be obtained. Therefore, during t...

Embodiment 3

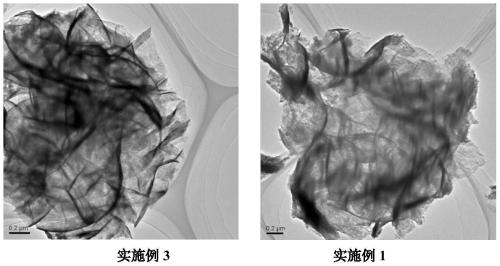

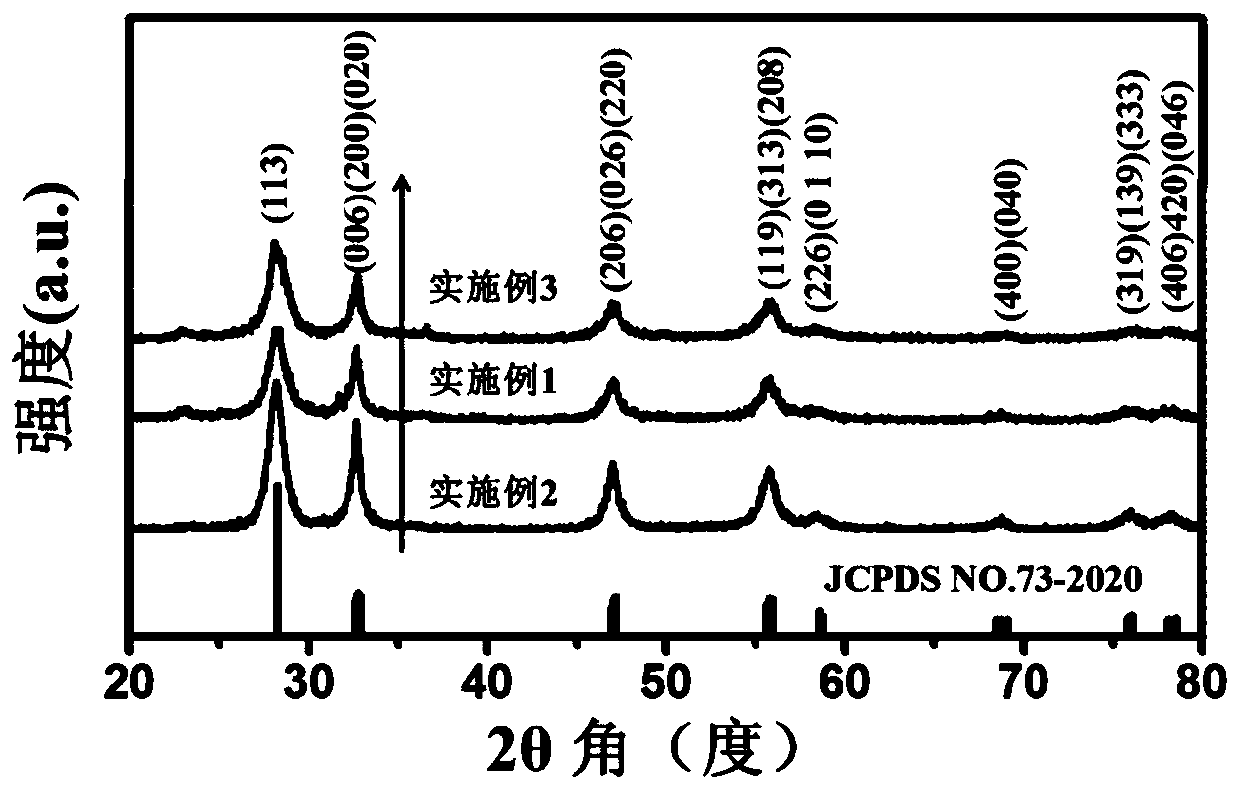

[0052] In order to test the influence of carbon doping on the photocatalytic material of ultra-thin bismuth tungstate nanosheets, in addition to not heat-treating the sample, and using deionized water, ethanol, and isopropanol to wash the sample several times to ensure that CTAB is cleaned, Other reaction conditions are as follows: sample addition order, stirring time CTAB:W:Bi ratio, reaction temperature (120°C), reaction time (24h), etc. are the same as in Example 1. Reference Example 1 carries out XRD, SEM, BET, CO 2 Adsorption and other tests. See the results separately Figure 1-9 .

[0053] Show comprehensively by above-mentioned result: by the carbon-doped ultrathin bismuth tungstate nanosheet photocatalyst material that obtains in embodiment 1, compare with the bulk bismuth tungstate of embodiment 2, specific surface area improves greatly, electron-hole pair Reduced recombination efficiency, enhanced visible light absorption performance, CO 2 The adsorption capacit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com