A kind of preparation method of graphene quantum dot sensitized europium and terbium co-doped layered hydroxide and product prepared therefrom

A technology of layered hydroxides and graphene quantum dots, applied in the preparation/processing of lanthanide oxides/hydroxides, rare earth metal oxides/hydroxides, rare earth metal compounds, etc., can solve the problem of GQD multiple Problems such as disordered layer structure and difficulty in precisely controlling the product structure achieve excellent optical properties, high luminous efficiency, and improved luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

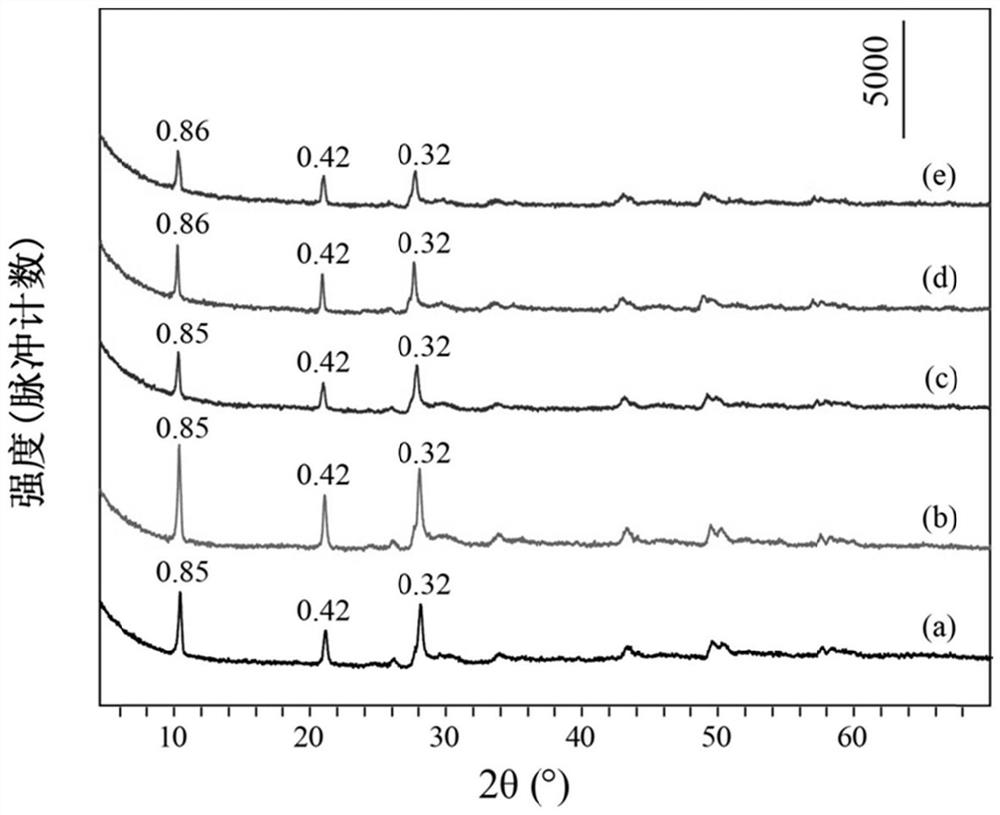

[0035] Take 0.99mmol of Tb(NO 3 ) 3 ·6H 2 O, 0.01 mmol of Eu(NO 3 ) 3 ·6H 2 O, 10 mmol NaNO 3 and 0.5 mmol of HMT dissolved in 80 mL of exhausted water, stirred evenly, then transferred to a 100 mL reaction kettle, reacted at 80 °C for 15 h, cooled to room temperature, washed and precipitated after centrifugation, and dried to obtain NO 3 -LEu 0.01 Tb 0.99 H.

[0036] Take 0.3 mmol of NO 3 -LEu 0.01 Tb 0.99 H and 3 mmol Na 3 C 6 H 5 O 7 ·2H 2 O was dissolved in 80 mL of exhausted water, stirred evenly, then transferred to a 100 mL reaction kettle, reacted at 95 °C for 20 h, cooled to room temperature, washed and precipitated after centrifugation, and dried to obtain CA-LEu 0.01 Tb 0.99 H.

[0037] Weigh 0.1g of CA-LEu 0.01 Tb 0.99 H was dispersed in 80 mL of exhausted water, 4 g of ammonia water was added, stirred evenly, and then transferred to a 100 mL reaction kettle, reacted at 150 °C for 10 h, cooled to room temperature, and after centrifugation, the s...

Embodiment 2

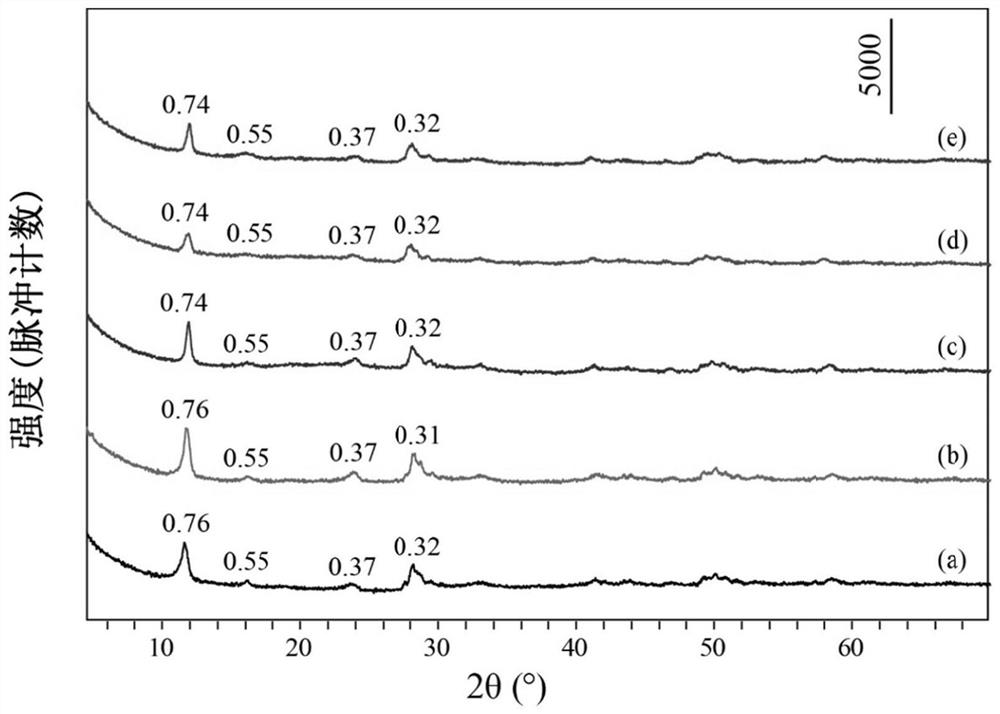

[0039] Take 0.91 mmol of Tb(NO 3 ) 3 ·6H 2 O, 0.09 mmol of Eu(NO 3 ) 3 ·6H 2 O, 14 mmol NaNO 3 and 1 mmol of HMT were dissolved in 80 mL of exhausted water, stirred evenly, and then transferred to a 100 mL reaction kettle, reacted at 90 °C for 12 h, cooled to room temperature, washed and precipitated after centrifugation, and dried to obtain NO 3 -LEu 0.09 Tb 0.91 H.

[0040] Take 0.3 mmol of NO 3 -LEu 0.09 Tb 0.91 H and 4.5 mmol Na 3 C 6 H 5 O 7 ·2H 2 O was dissolved in 80 mL of exhausted water, stirred evenly, then transferred to a 100 mL reaction kettle, reacted at 90 °C for 24 h, cooled to room temperature, washed and precipitated after centrifugation, and dried to obtain CA-LEu 0.09 Tb 0.91 H.

[0041] Weigh 0.1g of CA-LEu 0.09 Tb 0.91 H was dispersed in 80 mL of exhausted water, 5 g of ammonia water was added, stirred evenly, and then transferred to a 100 mL reaction kettle, reacted at 180 °C for 8 h, cooled to room temperature, and after centrifugati...

Embodiment 3

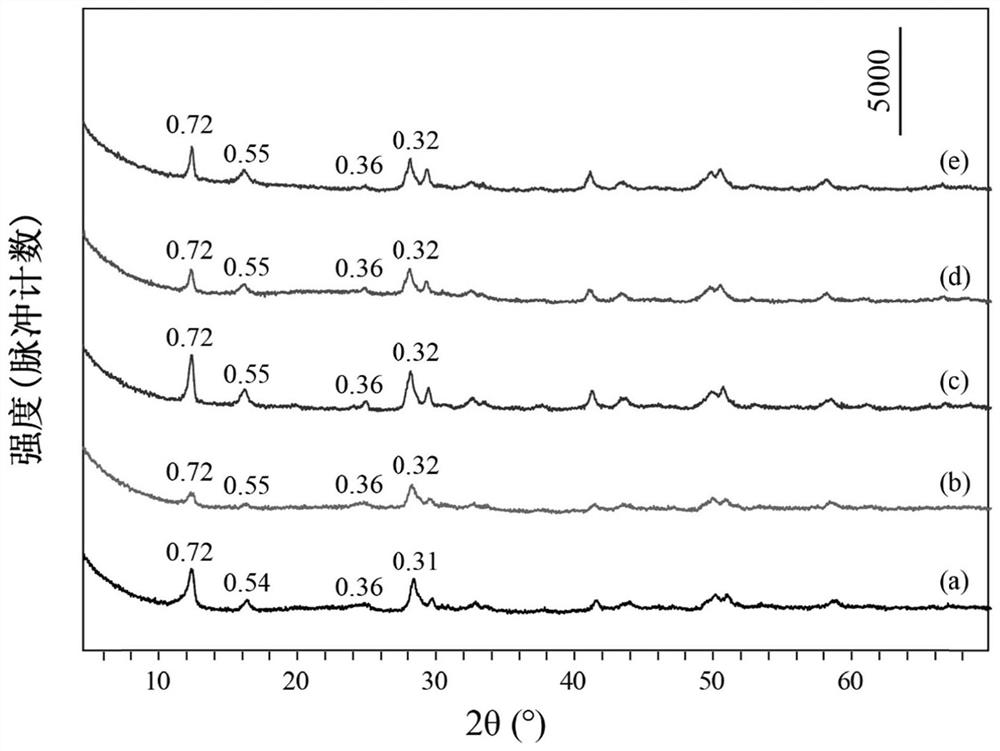

[0043] Take 0.5mmol of Tb(NO 3 ) 3 ·6H 2 O, 0.5 mmol of Eu(NO 3 ) 3 ·6H 2 O, 15 mmol NaNO 3 and 1.5mmol of HMT were dissolved in 80mL of exhausted water, stirred evenly and then transferred to a 100mL reaction kettle, reacted at 80°C for 15h, cooled to room temperature, washed and precipitated after centrifugation and dried to obtain NO 3 -LEu 0.5 Tb 0.5 H.

[0044] Take 0.3 mmol of NO 3 -LEu 0.5 Tb 0.5 H and 4 mmol Na 3 C 6 H 5 O 7 ·2H 2 O was dissolved in 80 mL of exhausted water, stirred evenly, then transferred to a 100 mL reaction kettle, reacted at 95 °C for 20 h, cooled to room temperature, washed and precipitated after centrifugation, and dried to obtain CA-LEu 0.5 Tb 0.5 H.

[0045] Weigh 0.1g of CA-LEu 0.5 Tb 0.5 H was dispersed in 80 mL of exhausted water, 4.8 g of ammonia water was added, stirred evenly, and then transferred to a 100 mL reaction kettle, reacted at 150 °C for 10 h, cooled to room temperature, and centrifuged, and the solid was wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com