Perovskite memristor and preparation method thereof

A perovskite and memristor technology, applied in the field of perovskite memristor and its preparation, can solve the problems of poor stability of perovskite and inability to completely solve the instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

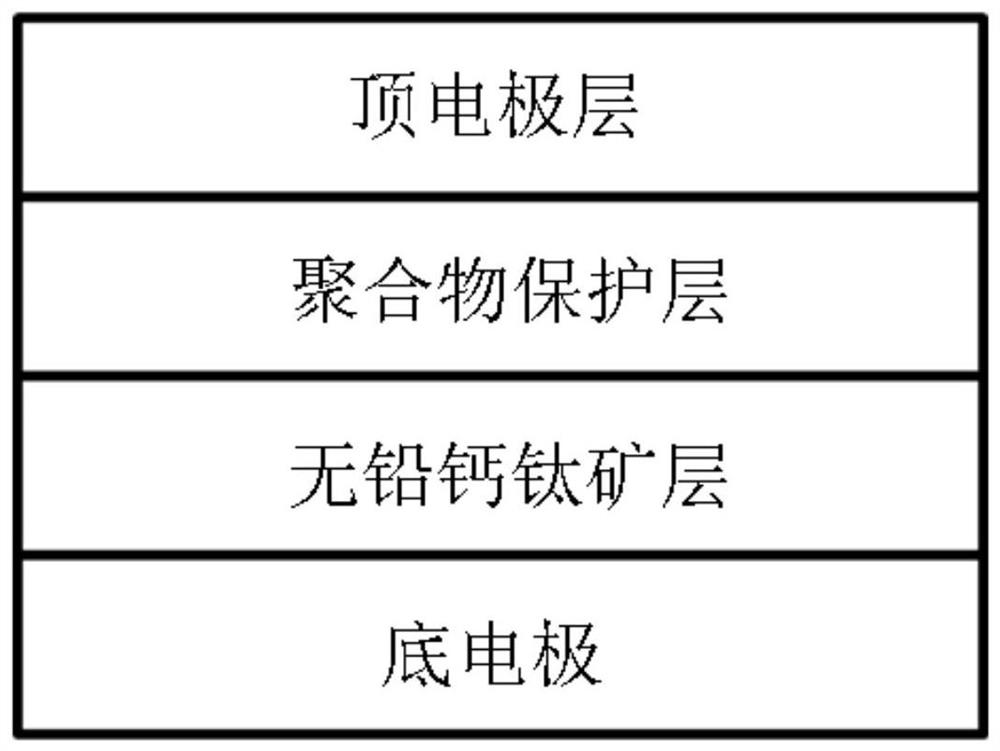

[0035] Another embodiment of the present invention provides a method for preparing the perovskite memristor described above, comprising the following steps:

[0036] (1) Spin-coat the lead-free metal halide perovskite precursor solution on the bottom electrode by thermal dynamic spin coating, and then anneal at 100-200°C to form a lead-free perovskite layer on the bottom electrode;

[0037] (2) spin coating a polymer solution on the lead-free perovskite layer, and then annealing at 80°C-100°C to form a polymer protective layer on the lead-free perovskite layer;

[0038] (3) preparing a top electrode on the polymer protective layer by thermal evaporation at an evaporation rate of 0.1-0.3 nm / s, forming a top electrode layer on the polymer protective layer to obtain the perovskite memristor.

[0039] Preferably, the thermal dynamic spin coating method specifically includes: preheating the bottom electrode at 50°C-80°C and keeping it warm, and then putting it on a spin coater for ...

Embodiment 1

[0044] This embodiment provides a method for preparing a perovskite memristor, the method comprising the following steps:

[0045] (1) Pretreatment of the bottom electrode: Use acetone and ethanol to ultrasonically clean the glass (ITO) coated with indium tin oxide for 20 minutes, remove the organic matter on the surface of the ITO, then wash it with deionized water, and finally put it into a UV ozone cleaner Medium treatment for 40 minutes for surface modification.

[0046] (2)AgBiI 4 Preparation of precursor solution: silver iodide and bismuth iodide were mixed and dissolved in DMSO solution at a mass ratio of 1:1, with a concentration of 1M.

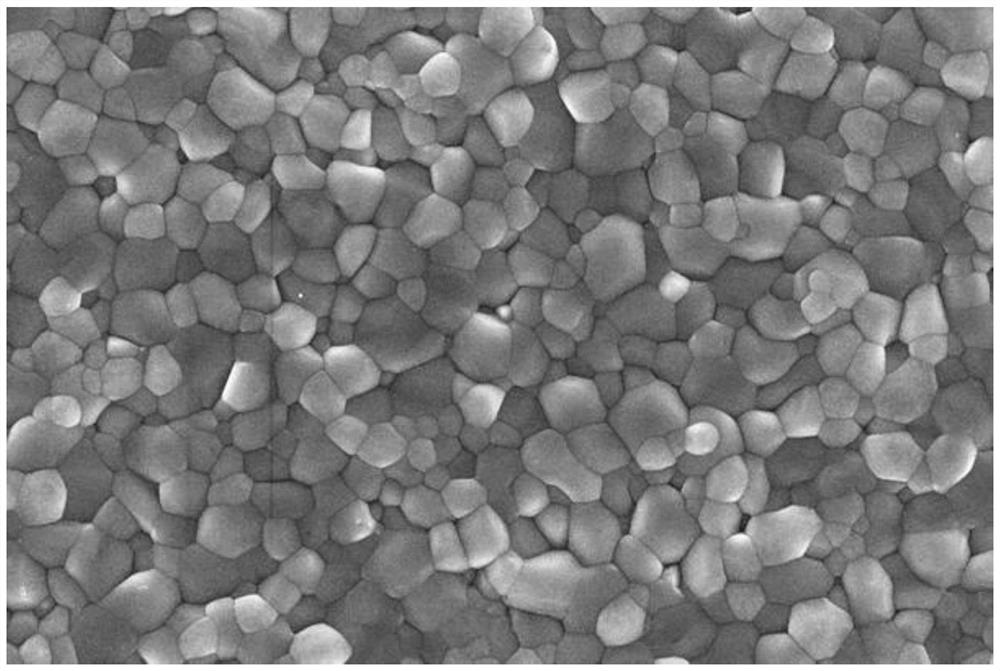

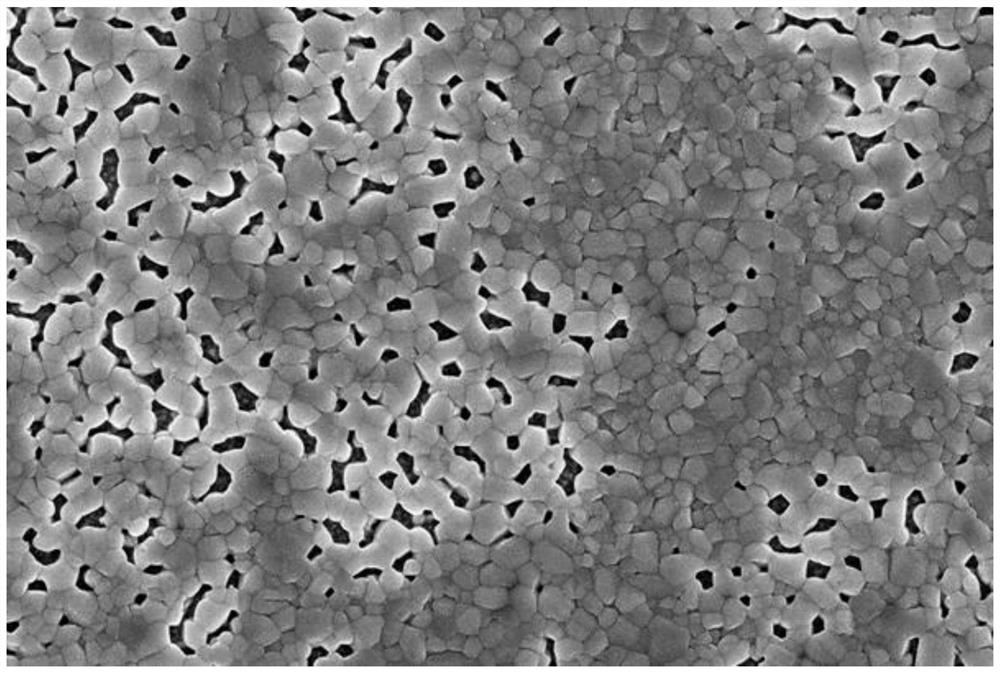

[0047] (3) Preparation of lead-free perovskite layer: AgBiI was spin-coated on the pretreated bottom electrode by thermal dynamic spin coating method 4 precursor solution, and then annealed at 100°C to form AgBiI on the bottom electrode 4 perovskite layer. Among them, the bottom electrode is preheated at 60°C, and then placed on a...

Embodiment 2-5

[0054] This example uses the same preparation method as Example 1 to prepare a perovskite memristor. The process parameters of each step in Examples 2-5 are different. The differences between Examples 2-5 and Example 1 are listed in Table 1. show.

[0055] Table 1 Process parameters of steps in the preparation method of perovskite memristor

[0056]

[0057] In the perovskite memristor prepared by Example 2-5, AgBiI 4 The perovskite layers are all dense polygonal nanoparticle structures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com