Low-moisture ceramic diaphragm, preparation method and lithium battery

A ceramic diaphragm, low-moisture technology, used in lithium batteries, non-aqueous electrolyte batteries, battery pack components, etc., can solve the problems of reducing water content, reducing water content in diaphragms, and high water content in internal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] On the other hand, the present invention also provides a preparation method of a low-moisture ceramic diaphragm, comprising the following steps:

[0036] (1) Preparation of CMC-g-AM / SiO 2 : Into the distilled water that is dissolved with CMC and feed nitrogen and add initiator simultaneously, then add AM monomer (acrylamide), crosslinking agent N, N-methylenebisallylamine and silica sol to mix and stir, then stir The reacted product was sequentially saponified, washed, vacuum dried, crushed and ground to obtain CMC-g-AM / SiO 2 ;

[0037] It should be noted that in this step, since the inorganic material silica sol is a highly active adsorption material with a porous structure, and it has many characteristics that other similar materials are difficult to replace: high adsorption performance and good thermal stability, so the silica sol absorbs water. Fast, and can absorb about 40% of its own weight of water, but dehydration usually needs to be carried out at a temperatu...

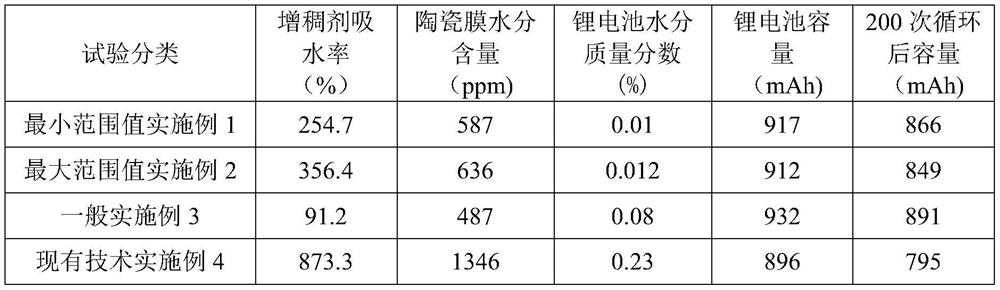

Embodiment 1

[0054] (1) Preparation of CMC-g-AM / SiO 2 : Add 0.4kg of CMC to a three-necked flask, add an appropriate amount of distilled water to dissolve, stir in a water bath at 50°C for 15 minutes, pass nitrogen and add 40g of initiator; weigh 2kg of AM monomer and put it into a small beaker, add a small amount of Dissolve in distilled water, then add 1g of cross-linking agent N, N-methylenebisallylamine and 0.1kg of silica sol; stir the mixture until it is evenly mixed and fully dissolved, then add it dropwise to the three-necked flask for the above reaction, stir, and react The product was obtained after 3 hours; the product was aged, then saponified by adding an appropriate amount of NaOH at an appropriate water bath temperature, taken out after 30 minutes, washed, vacuum dried, crushed, ground and packed into bags for later use.

[0055] (2) Preparation of low-moisture ceramic slurry: first add 19kg of deionized water to tank A, then add 1kg of CMC-g-AM / SiO to tank A 2 Stir overnig...

Embodiment 2

[0059] (1) Preparation of CMC-g-AM / SiO 2 : Add 1kg of CMC to a three-neck flask, add an appropriate amount of distilled water to dissolve, stir in a water bath at 70°C for 15 minutes, blow nitrogen and add 160g of initiator; weigh 2kg of AM monomer and put it into a small beaker, add a small amount of distilled water Dissolve, then add 4g of cross-linking agent N, N-methylenebisallylamine and 0.4kg of silica sol; stir the mixture until it is evenly mixed and fully dissolved, then drop it into the three-necked flask of the above reaction, stir, and react for 3h Finally, the product is obtained; the product is aged, then saponified by adding an appropriate amount of NaOH at an appropriate water bath temperature, taken out for washing after 30 minutes, vacuum-dried, crushed, ground and packed into bags for later use.

[0060] (2) Preparation of low-moisture ceramic slurry: first add 9kg of deionized water to tank A, then add 1kg of CMC-g-AM / SiO to tank A 2 Stir overnight to make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

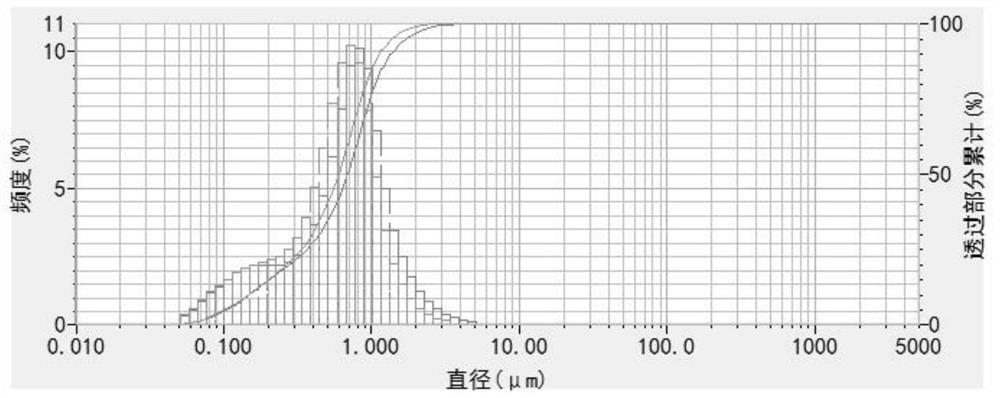

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com