Plant factory based on fan frequency conversion adjustment

A plant and factory technology, which is applied in the field of plant factories based on fan frequency conversion adjustment, can solve the problems of inability to obtain cold air in a timely and effective manner and difficult to control temperature, and achieve the effects of convenient operation, convenient maintenance and convenient management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

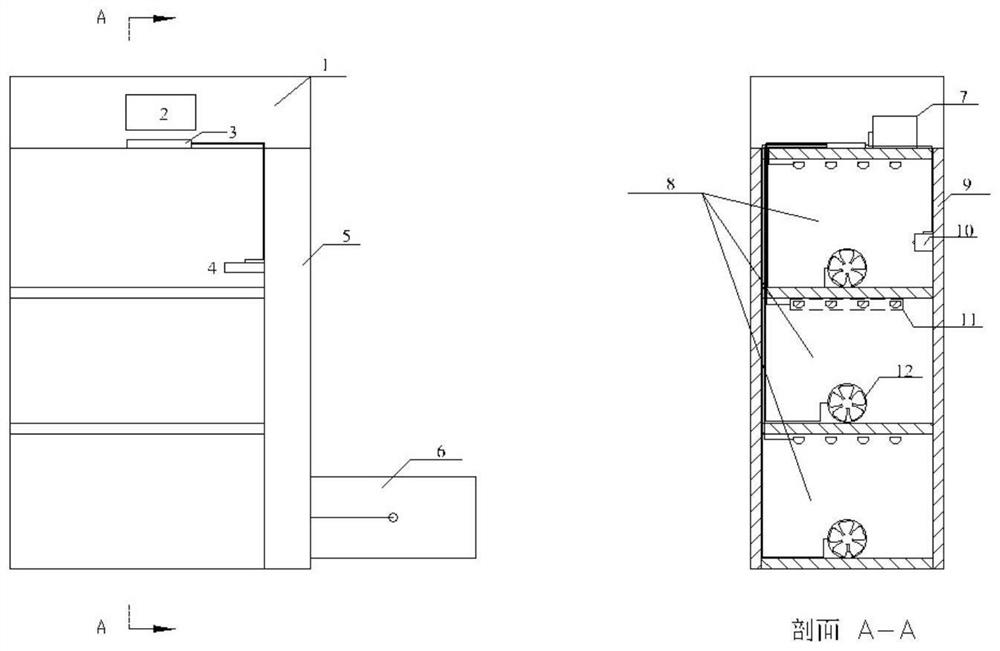

[0030]The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

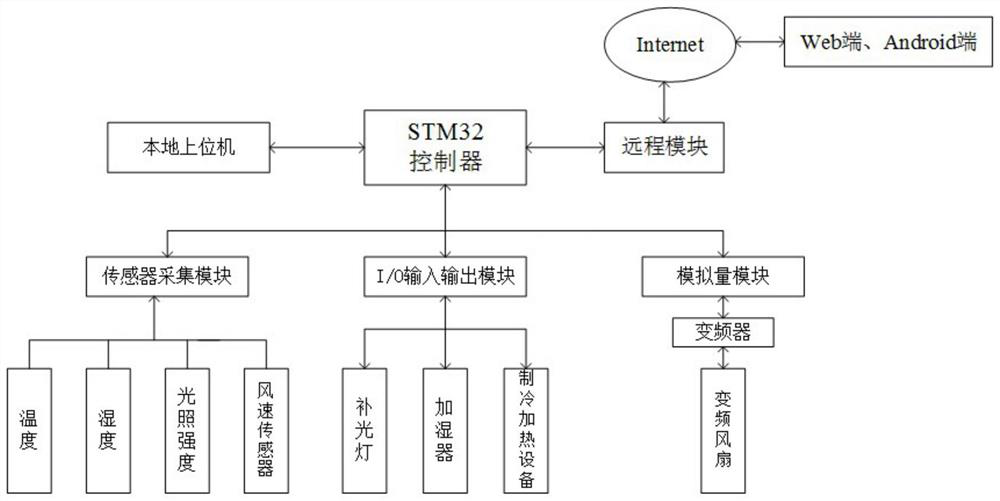

[0031]Such asfigure 1 As shown, the housing of the present invention is made of 4040 aluminum alloy profile, and above the casing, including control module 3, humidifier 7, inverter, etc., wherein the humidifier is connected to the I / O input and output port of the control module. Communication with the analog module of the inverter and the control module. The housing is provided with a 7-inch touch screen 2, and through the MODBUS communication protocol and the control module interactive data information, the single machine controls the system's environmental data display and the frequency conversion fan and other actuator control, and the 7-inch touch screen 2 can be set to manual and automatic mode. Automatic mode can automatically control plant fill light 11, frequency conversion fan 12 and other actuators to achieve the target value of the expected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com