Monatomic metal catalyst as well as preparation method and application thereof

A metal catalyst and atomic technology, applied in the field of single-atom metal catalysts and their preparation, can solve the unsatisfactory problems of single-atom catalysts, and achieve the effects of stable output, high output, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

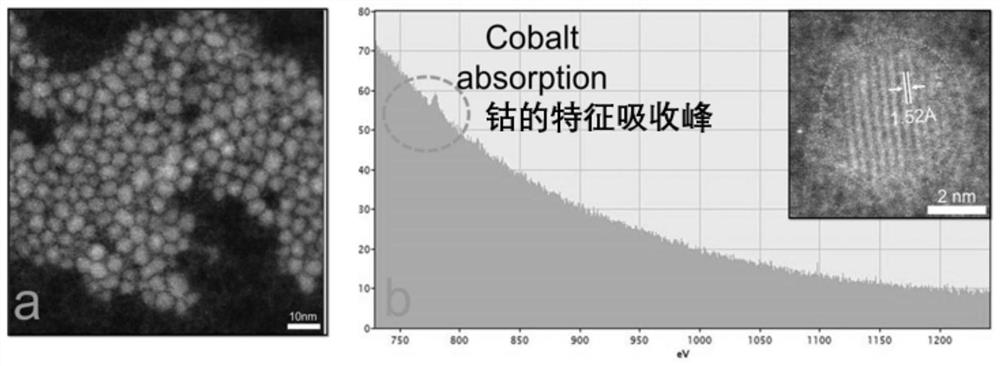

[0035] Example 1: Preparation of a catalyst with monoatomic cobalt dispersion

[0036] Preparation of catalysts Co@Si@SiO with monatomic cobalt dispersion on the surface x (x is an integer or decimal between 0 and 2), and its specific preparation process is as follows:

[0037] Step 1. Under nitrogen atmosphere, tetramethoxysilane (24mL), isopropanol (16mL), water (20mL), acetonitrile (20mL), nitric acid (48mmol) and cobalt nitrate solution (0.17mg / mL, 10mL) into a round-bottomed flask and mixed, stirred until the system was completely dissolved, heated at 120°C, and continued to stir. When the system gelled and completely solidified, stop stirring; after aging for 48 hours, use deionized water and After washing with ethanol for 3 times, dry in an oven at 105°C for 24 hours, take it out, and grind it to a fine blue powder to obtain a hydrolyzed gel with uniform dispersion of metal cobalt ions (Co@HSiO x );

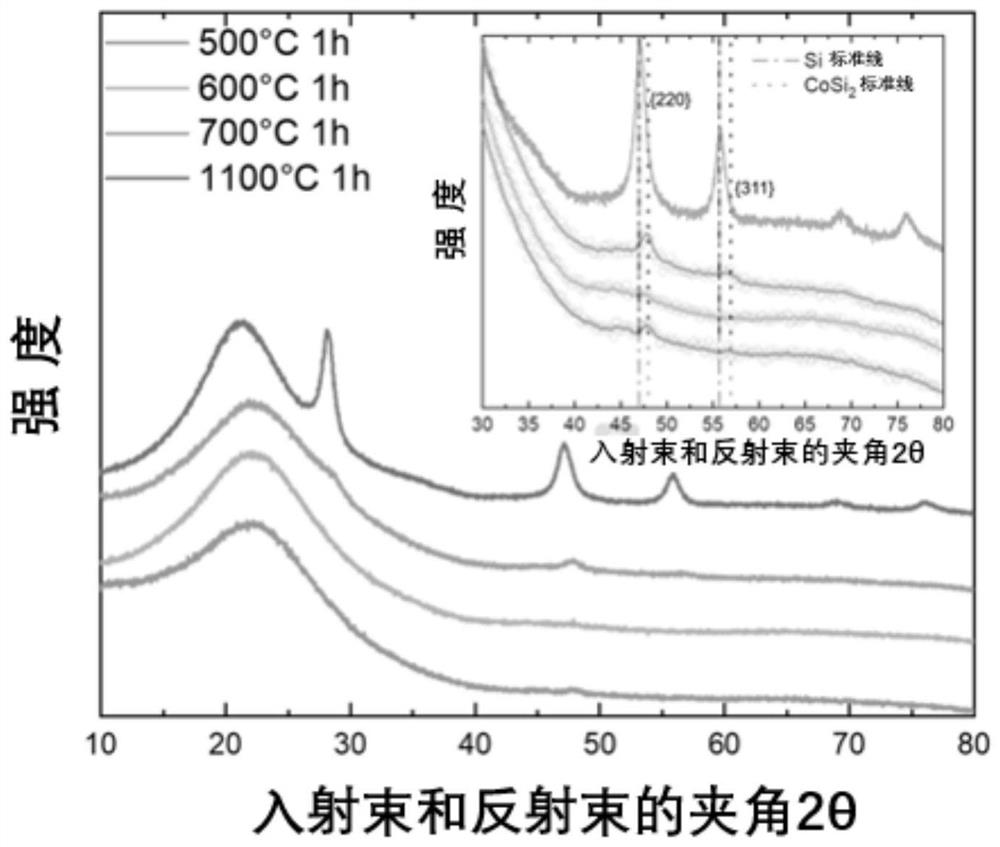

[0038] Step 2. Put the completely dried Co@HSiOx Place in a tube f...

Embodiment 2

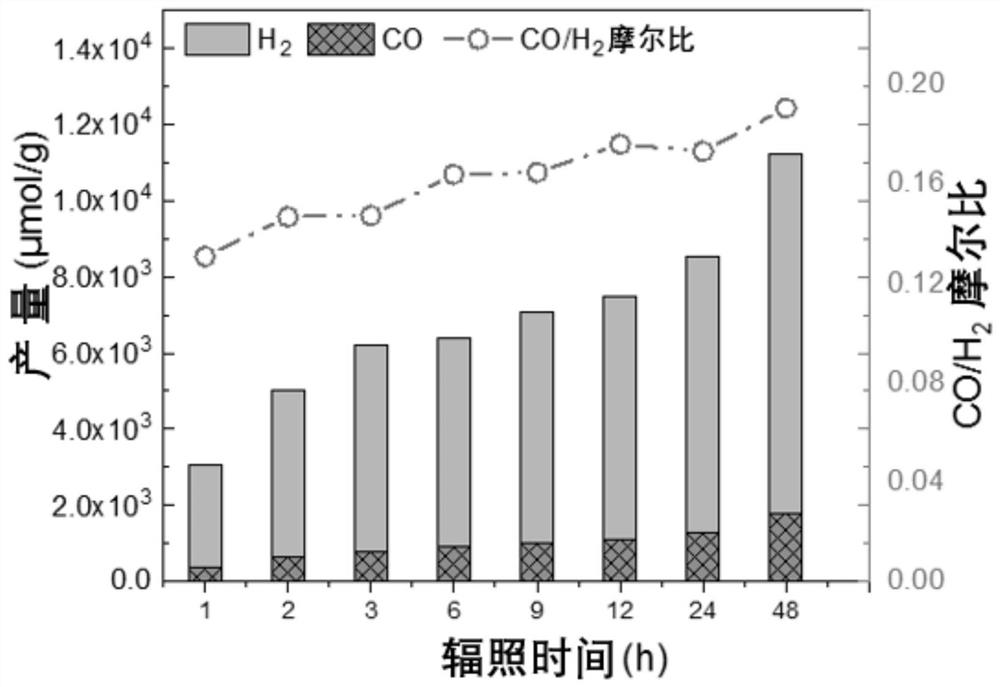

[0043] Example 2: Single-atom cobalt catalyst Co@Si@SiO x Photocatalytic reduction of carbon dioxide experiment

[0044] Set up experimental group 2: reduce the amount of cobalt nitrate solution in Example 1 by half, that is, use 5mL, and the other raw materials and their amounts are completely set according to Example 1, and then follow the same preparation method and steps in Example 1 A monoatomic cobalt catalyst is prepared.

[0045] Set up experimental group 3: increase the amount of cobalt nitrate solution in Example 1 by 10 times, that is, use 100mL, other raw materials and their amounts are completely set in accordance with Example 1, and then follow the same preparation method and steps in Example 1 A monoatomic cobalt catalyst is prepared.

[0046] Set up experimental group 4: increase the amount of cobalt nitrate solution in Example 1 by 5 times, that is, use 50mL, and the other raw materials and their amounts are completely set in accordance with Example 1, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com