Purple phosphorus nanosheet for lubricant as well as preparation method and application of purple phosphorus nanosheet

A technology of nano-sheets and lubricants, applied in the field of new nano-lubricating materials, can solve the problems of large size and thickness, large product size, uncontrollable, etc., and achieve the effects of making up for gaps in the friction field, good lubricating performance, and improving peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of purple phosphorus nanosheets for lubricants, comprising the following steps:

[0040] Add 2 mg of purple phosphorus powder into 20 mL of ethanol to form a dispersion liquid, and under the protection of nitrogen, at a temperature of 25 ° C, a power of 135 W, and a frequency of 80 KHz, ultrasonic stripping in a water bath for 2 hours; after the ultrasonic wave is completed, the obtained dispersion liquid Centrifuge at 3000rpm for 30min to collect the supernatant; centrifuge the collected supernatant at 12000rpm for 30min, take the precipitate, and vacuum dry at 50°C for 12h to obtain purple phosphorus nanosheets.

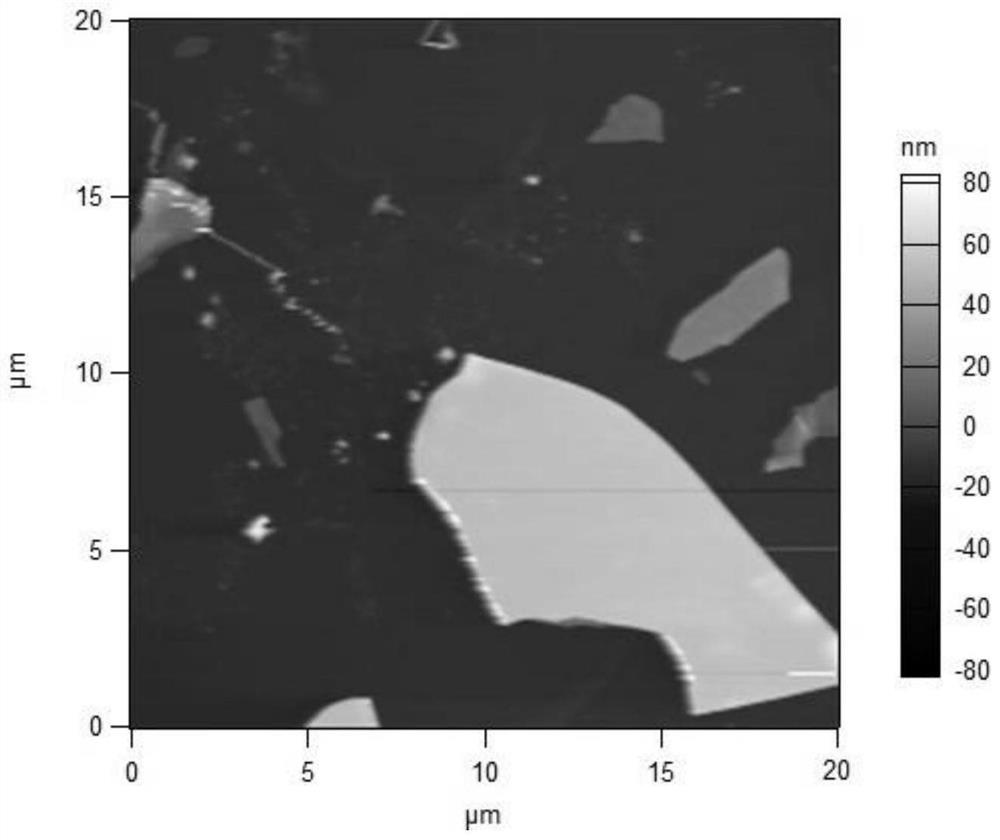

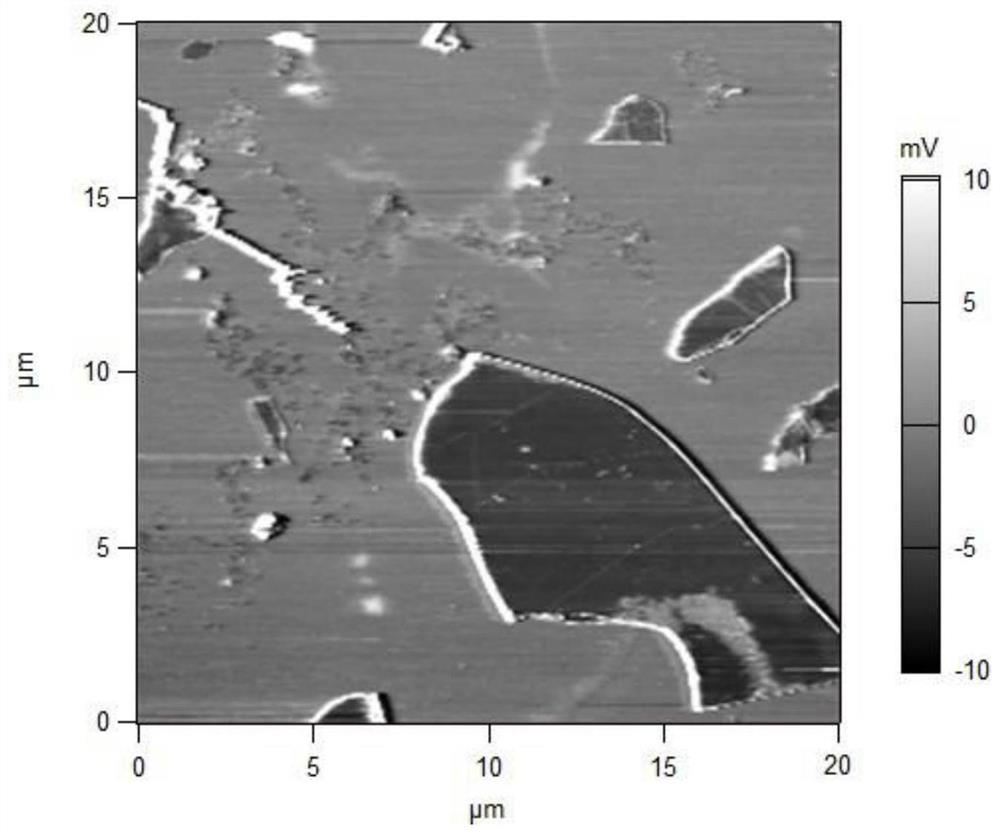

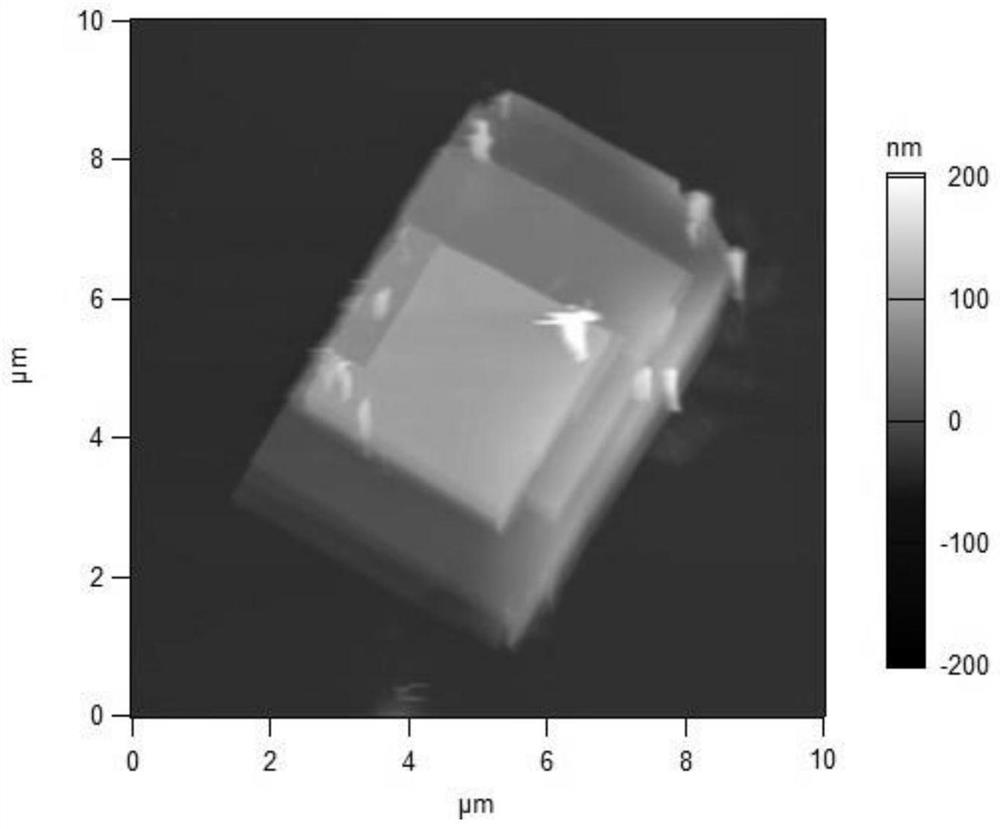

[0041] The atomic force microscope image of the purple phosphorus nanosheets for lubricants prepared in this example is as follows figure 1 shown, from figure 1 It can be seen that this method can prepare nanosheets with a lateral size of 0.5-10 μm and a thickness of 5-70 nm; its friction force microscope images are shown in figure 2 ...

Embodiment 2

[0043] A preparation method of purple phosphorus nanosheets for lubricants, comprising the following steps:

[0044] Add 10 mg of purple phosphorus powder into 100 mL of ethanol to form a dispersion. Under the protection of nitrogen, at a temperature of 25 ° C, a power of 90 W, and a frequency of 80 KHz, the water bath is ultrasonically stripped for 2 hours; after the ultrasonic wave is completed, the obtained dispersion is Centrifuge at 3000rpm for 30min to collect the supernatant; centrifuge the collected supernatant at 12000rpm for 30min, take the precipitate, and vacuum dry at 50°C for 12h to obtain purple phosphorus nanosheets.

Embodiment 3

[0046] A preparation method of purple phosphorus nanosheets for lubricants, comprising the following steps:

[0047] Add 20mg of purple phosphorus powder into 200mL of isopropanol to form a dispersion liquid. Under the protection of nitrogen, at a temperature of 25°C, a power of 75W, and a frequency of 80KHz, the water bath is ultrasonically stripped for 3 hours; after the ultrasonication is completed, the obtained The dispersion liquid was centrifuged at 3000rpm for 30min, and the supernatant was collected; the collected supernatant was centrifuged at 12000rpm for 30min, and the precipitate was taken, and vacuum-dried at 50°C for 12h to obtain purple phosphorus nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com