Method for separating synephrine from hesperidin waste liquid

A technology for hesperidin and hesperidin mother, applied in the field of separation of synephrine, can solve the problems of high COD content, difficult sewage treatment, complex composition of mother liquor, etc., so as to improve the recovery rate, solve the problem of sewage treatment, and the operation method can be improved. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

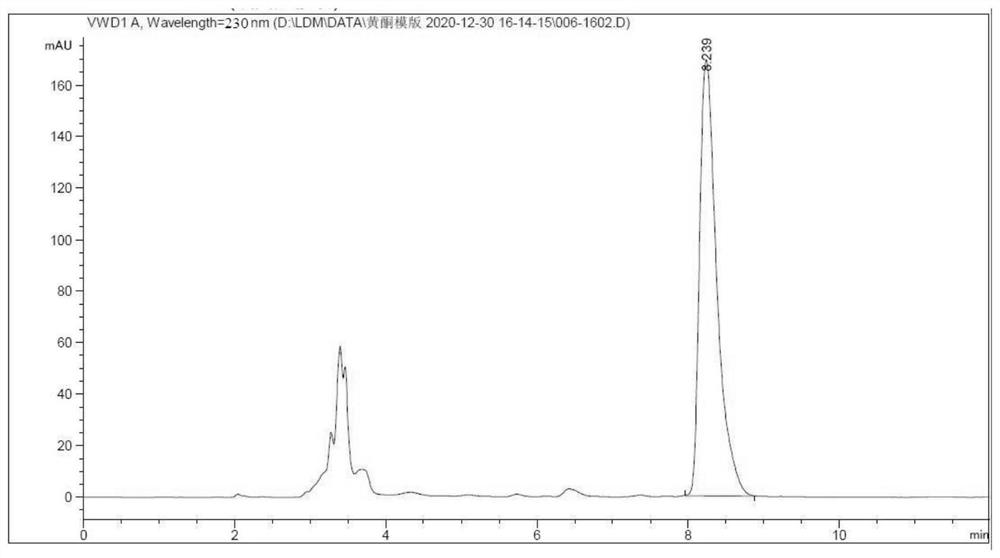

Image

Examples

Embodiment 1

[0050] The method for separating synephrine from hesperidin waste liquid, comprises the following steps:

[0051] S1. Put 300kg of pretreated C100E strong acid cationic resin into the stainless steel cylinder, put 10t of hesperidin mother liquor on the C100E strong acid cationic resin, and the speed of loading the hesperidin mother liquor is 7BV / h. After the sample is finished, it is eluted with water. The volume of water elution is 3.3BV, and the speed of water elution is 2BV / h. After the water elution, it is eluted with a strong alkali mixture. %NaOH and mass fraction are 0.3%KOH mixed solution, the volume of strong alkali mixed solution is 3.3BV, the flow rate of strong alkali mixed solution is 2BV / h, collect the eluate after strong alkali mixed solution elution, adopt the concentration of 10% hydrochloric acid adjusts the pH value of the eluent to 7 to obtain a neutralizing solution;

[0052] S2. Ultrafilter the neutralization solution with a 100nm ceramic membrane, then ...

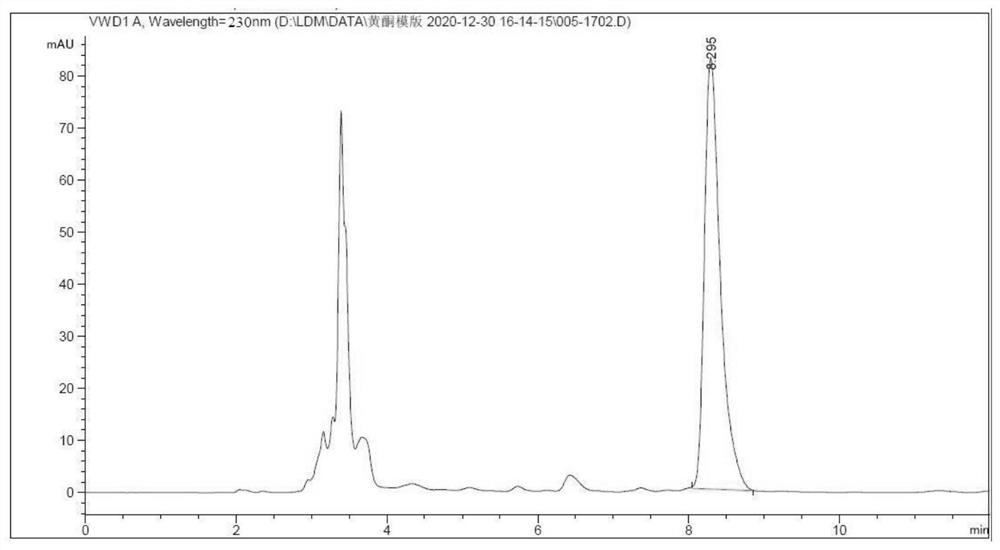

Embodiment 2

[0055] S1. Put 300kg of pretreated C100E strong acid cationic resin into the stainless steel cylinder, put 15t of hesperidin mother liquor on the C100E strong acid cationic resin, and the speed of loading the hesperidin mother liquor is 10BV / h. After the sample is finished, it is eluted with water. The volume of water elution is 3.34BV, and the speed of water elution is 3BV / h. After the water elution, it is eluted with a strong alkali mixed solution. %NaOH and mass fraction of 0.1% Ca(OH) 2 The mixed solution, the volume of the strong base mixed solution is 3.34BV, the flow rate of the strong base mixed solution is 3BV / h, the eluate after the strong base mixed solution is collected, and the concentration is 20% hydrochloric acid to adjust the pH of the eluent The value is 6.5, and the neutralizing solution is obtained;

[0056] S2. Ultrafilter the neutralization solution with a 50nm ceramic membrane, then concentrate it through a 50Da nanofiltration membrane, stir the concent...

Embodiment 3

[0059] S1. Put 300kg of pretreated C100E strong acid cationic resin into the stainless steel cylinder, put 15t of hesperidin mother liquor on the C100E strong acid cationic resin, and the speed of loading the hesperidin mother liquor is 10BV / h. After the sample is finished, it is eluted with water. The volume of water elution is 3.5BV, and the speed of water elution is 3BV / h. After the water elution, it is eluted with a strong alkali mixture. %Ca(OH) 2 And the mixed solution of the mixed solution whose mass fraction is 0.1% KOH, the volume of the strong alkali mixed solution is 3.5BV, the flow rate of the strong alkali mixed solution is 3BV / h, collect the eluate after the strong alkali mixed solution is eluted, and adopt the concentration Adjust the pH value of the eluent to 7 with 20% hydrochloric acid to obtain a neutralizing solution;

[0060] S2. Ultrafilter the neutralization solution with a 500nm ceramic membrane, then concentrate it through a 500Da nanofiltration membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com