Coating for chromium-free oriented electromagnetic steel plate, preparation method thereof, and preparation method of chromium-free oriented electromagnetic steel plate with coating

A technology for electromagnetic steel plates and coatings, applied in the direction of metal material coating process, coating, manufacturing tools, etc., can solve the problems of corrosion resistance, poor tension, hazards, etc., and achieve improved water resistance, good moisture absorption resistance, and low pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained and illustrated below in conjunction with specific embodiments, however, the explanation and illustration do not constitute undue limitations on the technical solution of the present invention.

[0024] Examples and comparative examples

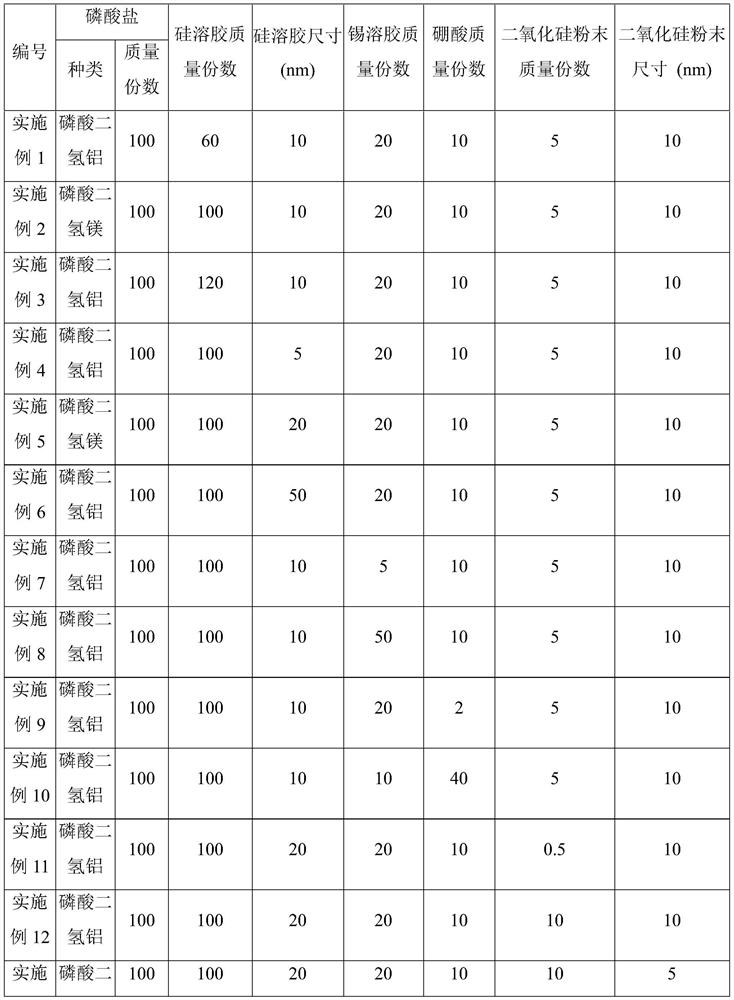

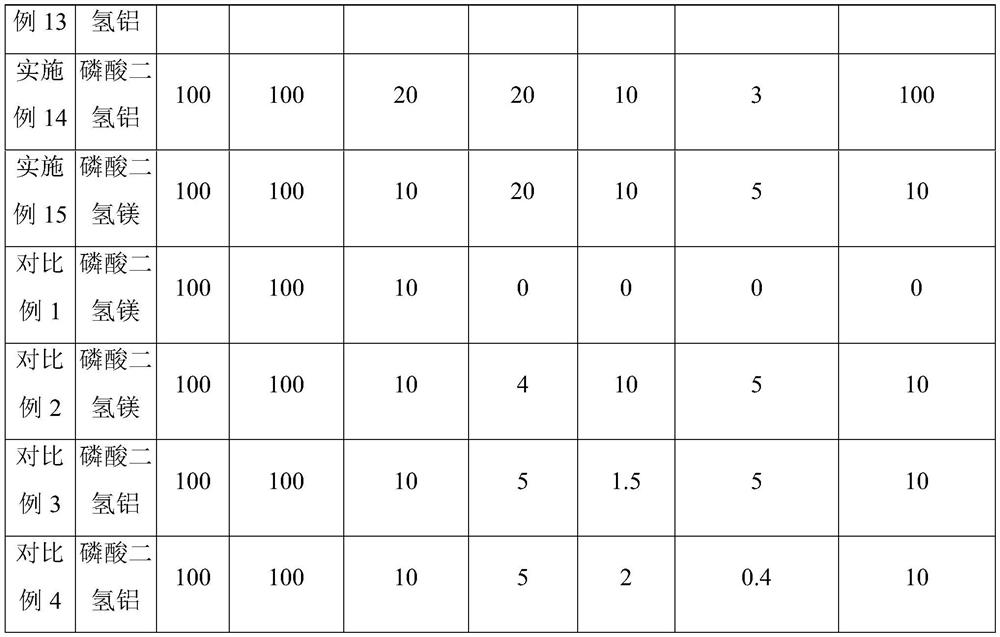

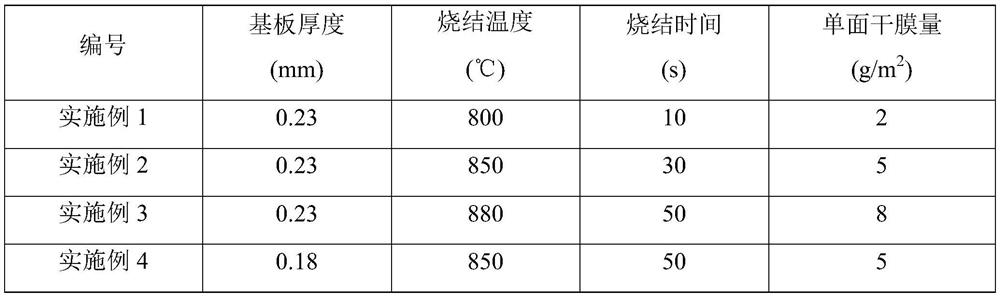

[0025]The present invention is a coating for chromium-free oriented electrical steel sheets. The raw materials of the coating are as follows: 100 parts of phosphate, 60-120 parts of silica sol, 5-50 parts of tin oxide sol, 2-40 parts of boric acid and 0.5- 10 parts of silica powder.

[0026] The specific preparation method is as follows: mechanically disperse or ultrasonically disperse the silica powder in all or part (it should be noted here that the dispersion in all or part of the colloidal silica is for the convenience of actual storage and transportation, and the actual amount added How much has little effect on the performance of the final coating) colloidal silica to form a stable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com