Laminar flow wing transition position measurement image processing method based on temperature-sensitive paint technology

A technology for measuring images and processing methods, which is applied in the field of image information processing of wind tunnel optical measurement and test technology, can solve problems such as low spatial resolution, increased model design and processing costs, and large flow interference, achieving high spatial resolution and realizing Real-time calculation and high operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

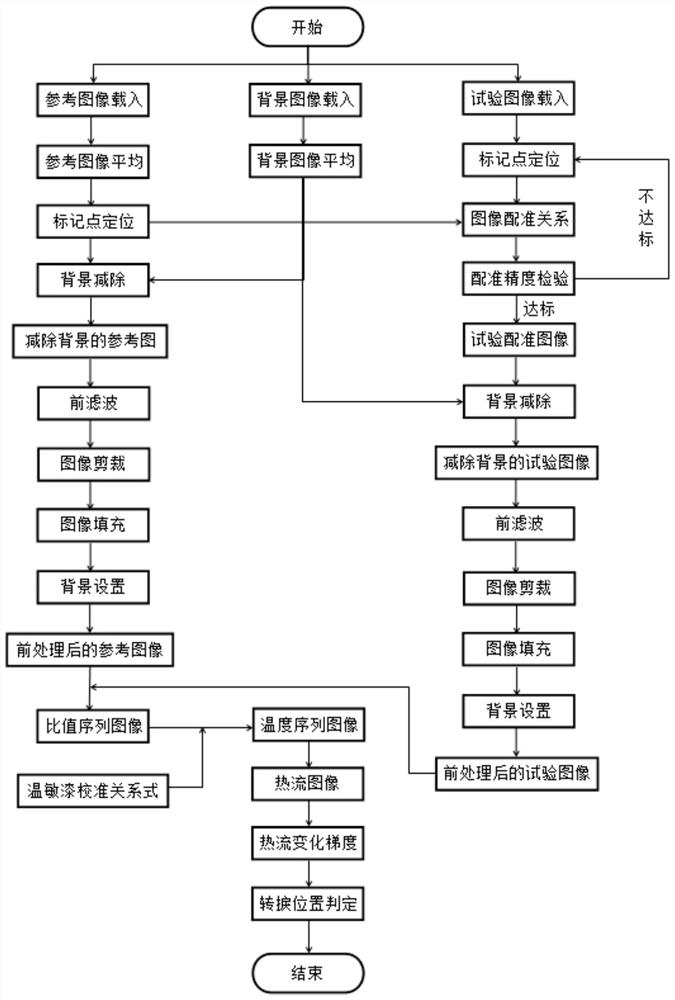

Method used

Image

Examples

Embodiment 1

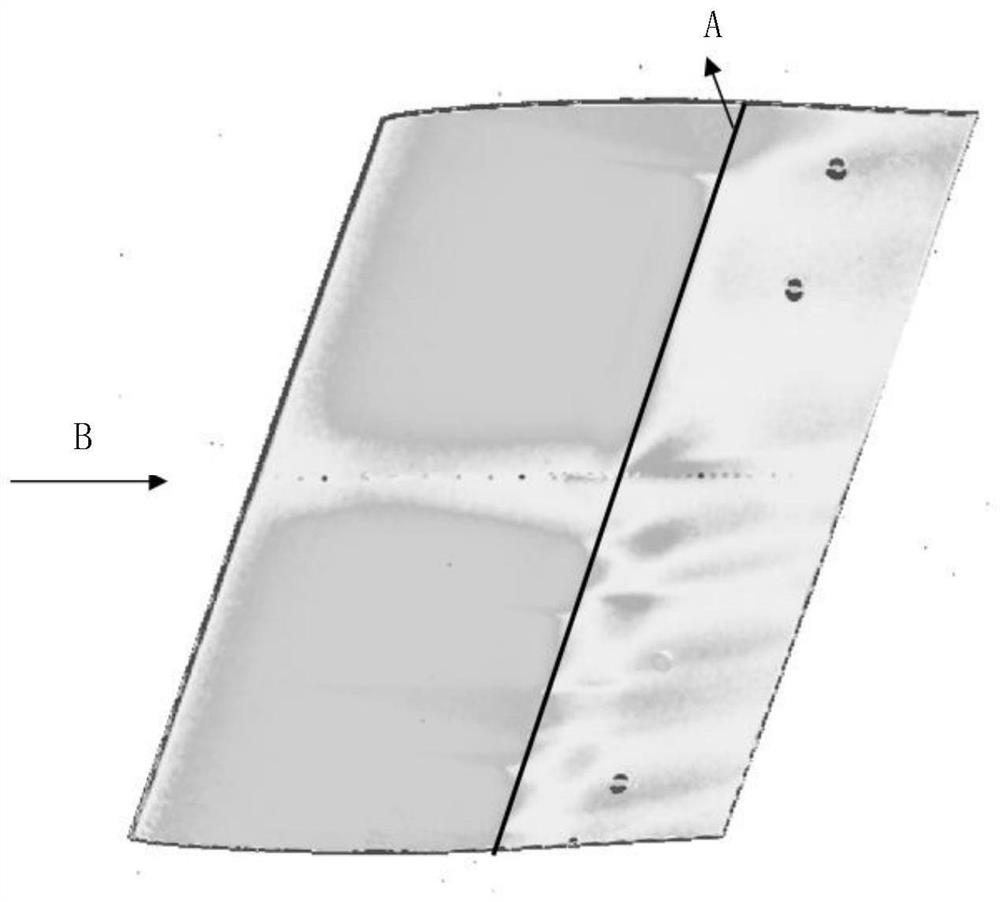

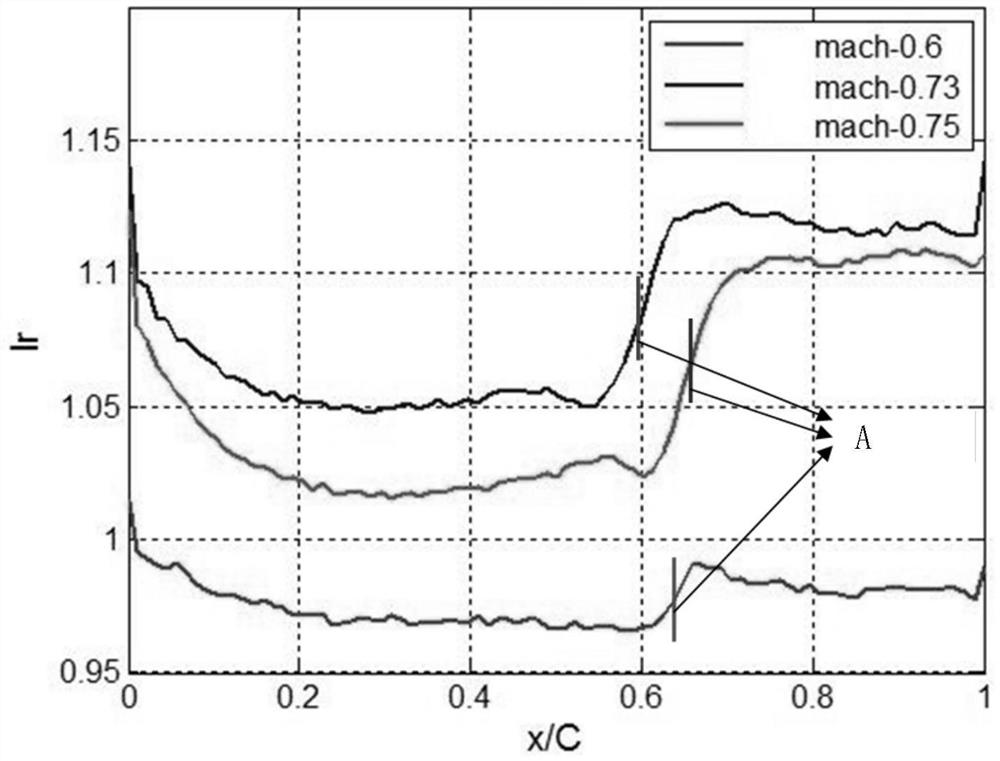

[0147] The test model of this embodiment is a laminar airfoil model with a sweep angle of 20° and a chord length of 200 mm. The surface of the model is covered with a temperature-sensitive paint primer and a temperature-sensitive paint finish paint sequentially from bottom to top. The measuring device includes a temperature-sensitive paint, a camera, an exciting light source, a synchronous trigger and an industrial computer for data processing. The temperature-sensitive paint is composed of two parts: the temperature-sensitive paint primer and the temperature-sensitive paint topcoat. The temperature-sensitive paint primer is called the base emission layer, which is a white primer containing silicon dioxide. It is sprayed on the surface of the model to improve the model surface. Adhesiveness, enhancing the luminous intensity of probe molecules and thermal isolation. The temperature-sensitive paint finish is called a polymer functional layer, which contains temperature-sensitive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com