Sapphire-based GaN quasi-vertical Schottky diode reverse electric leakage improvement method and Schottky diode

A Schottky diode, reverse leakage technology, applied in the direction of diodes, circuits, electrical components, etc., can solve the problems of reduced device performance and application, large reverse leakage, etc., to achieve low cost, reduced reverse leakage, and prevent shedding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The GaN sample whose mesa was etched was cleaned in acetone, isopropanol, and deionized water in sequence. After the GaN mesa was etched, it was treated in RTA rapid annealing in an Ar environment for 5 minutes and the temperature was controlled at 400°C.

Embodiment 2

[0050] The GaN sample whose mesa was etched was cleaned in acetone, isopropanol, and deionized water in sequence. After the GaN mesa was etched, it was treated in RTA rapid annealing in an Ar environment for 5 minutes, and the temperature was controlled at 420°C.

Embodiment 3

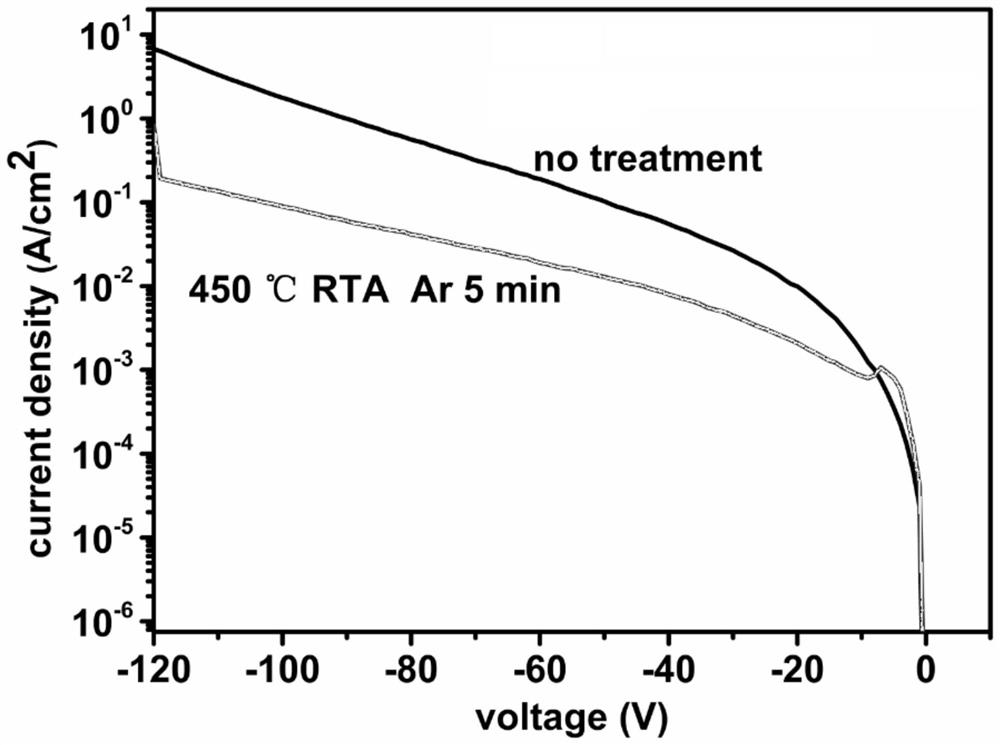

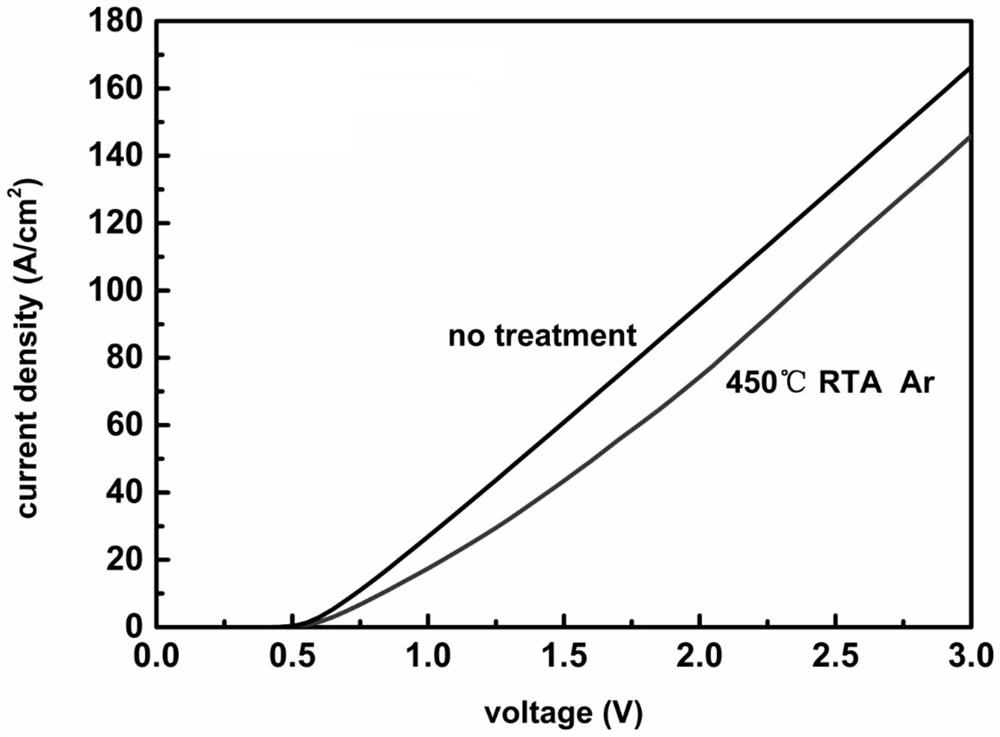

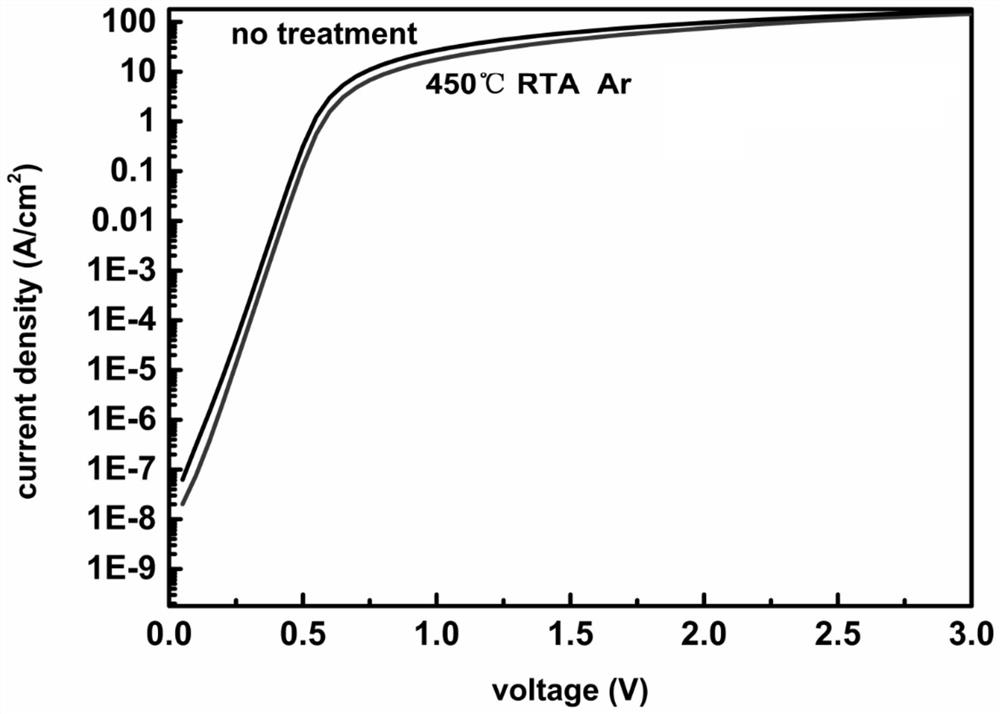

[0052] The GaN sample whose mesa was etched was cleaned in acetone, isopropanol, and deionized water in sequence. After the GaN mesa was etched, it was treated in RTA rapid annealing in an Ar environment for 5 minutes, and the temperature was controlled at 450°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com