Bread with high content of oat flour and preparation method thereof

A technology of oat flour and bread, which is applied in the direction of dough preparation, dough processing, pre-baked dough processing, etc. It can solve the problems of bread with high oat content, such as difficulty in baking, poor texture, poor elasticity, and high hardness, and achieve convenience for large-scale production. Large-scale industrial production, high quality, anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) In terms of parts by mass, weigh 50 parts of oat flour, 12.5 parts of gluten powder, 37.5 parts of wheat flour, 8 parts of butter, 6 parts of white granulated sugar, 1.5 parts of salt, and 1.5 parts of yeast;

[0035] (2) Add some parts of water to the mixed powder (not including butter), the amount of water added is the volume of water that needs to be added when the maximum consistency of the dough in the powder test reaches 500FU, and the stirrer (model is WTN-25, Wuxi United Wistron Machinery Co., Ltd.) stirred at low speed for 3 minutes, then at high speed for 2 minutes, until the dough was basically formed, added 8 parts of butter and kneaded at low speed until the gluten was fully developed to obtain a dough;

[0036] (3) said dough is carried out shaping, packing, and the dough after packing is 170g;

[0037] (4) Proof the dough after packing for 40 minutes at 80% humidity and 35°C, then bake and cool for 60 minutes at room temperature to obtain the brown ri...

Embodiment 2

[0054] (1) In terms of parts by mass, weigh 50 parts of atmospheric pressure steamed oat flour (same as Example 1), 12.5 parts of gluten powder, 37.5 parts of wheat flour, 8 parts of butter, 6 parts of white granulated sugar, 1.5 parts of salt, yeast 1.5 parts, several parts of β-glucanase;

[0055] (2) Add some parts of water to the mixed powder (not including butter), the amount of water added is the volume of water that needs to be added when the maximum consistency of the dough reaches 500FU in the powder quality test, and the water absorption in Table 4 is the final added amount. water volume. Stir with a mixer (model WTN-25, Wuxi United Wistron Machinery Co., Ltd.) at low speed for 3 minutes, then at high speed for 2 minutes until the dough is basically formed, add 8 parts of butter and knead at low speed until the gluten is fully developed to obtain a dough;

[0056] (3) said dough is carried out shaping, packing, and the dough after packing is 170g;

[0057] (4) Proo...

Embodiment 3

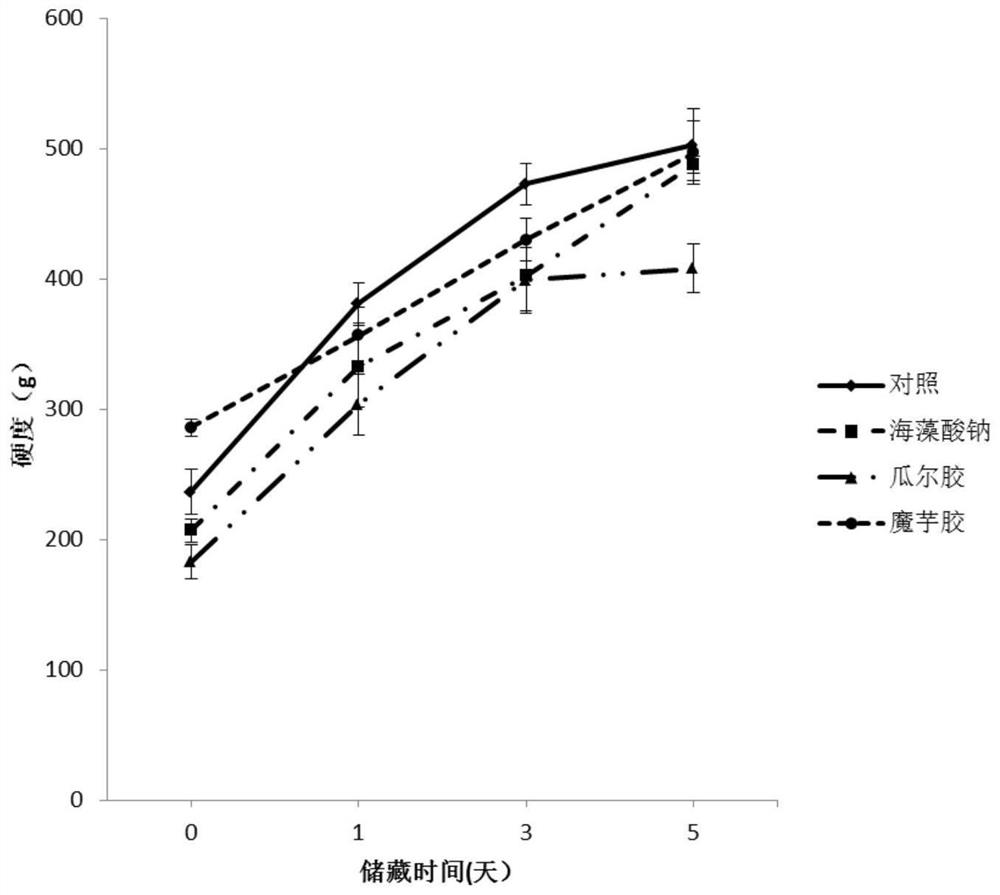

[0073] (1) In terms of parts by mass, weigh 50 parts of atmospheric pressure steamed oat flour (same as Example 1), 12.5 parts of gluten powder, 37.5 parts of wheat flour, 8 parts of butter, 6 parts of white granulated sugar, 1.5 parts of salt, yeast 1.5 parts, 0.00030 parts of β-glucanase, 0.5 parts of hydrocolloid;

[0074] (2) Add 75 parts of water to the mixed powder (not including butter), stir for 3 minutes at low speed with a stirrer (model is WTN-25, Wuxi United Wistron Machinery Co., Ltd.), then stir for 2 minutes at high speed until The dough is basically formed, add 8 parts of butter and knead at a low speed until the gluten is fully developed, and the dough is obtained;

[0075] (3) said dough is carried out shaping, packing, and the dough after packing is 170g;

[0076] (4) Proof the dough after packing for 40 minutes at 80% humidity and 35°C, then bake and cool for 60 minutes at room temperature to obtain the brown rice oat bread product, wherein the baking The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com