Flow field optimization method for two-stage serial tower type wet flue gas desulfurization device

A wet desulfurization and optimization method technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of large computing power and computing time, fast computing speed, insufficient resources to calculate, etc., to save computing Resources and computing time, saving computing resources, optimizing spray layer layout and effect of synergistic ring design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the examples.

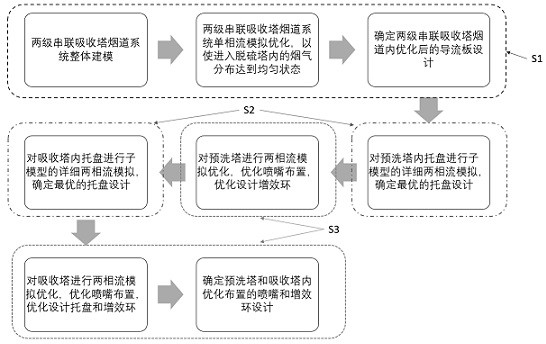

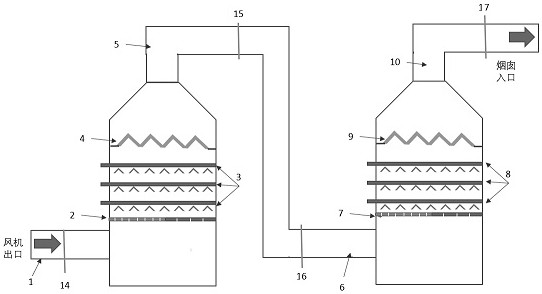

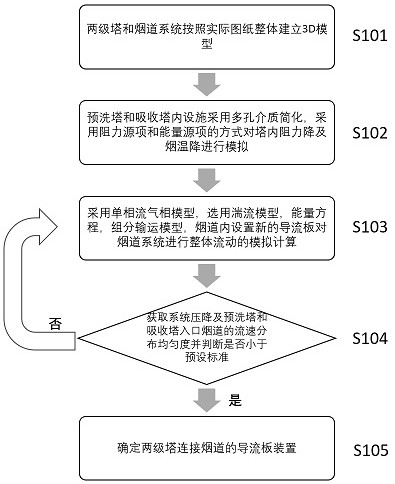

[0038] The invention discloses a method for optimizing the flow field of a two-stage serial tower type flue gas wet desulfurization device. The method can adopt the overall single-phase flow field simulation optimization according to the flow characteristics of the desulfurization system. The model is simple, the calculation amount is small, and the Accurately simulate the flue gas flow in the flue and quickly obtain an accurate deflector optimization scheme; in order to accurately simulate the performance of the tray, a tray sub-model was developed to calculate the two-phase flow response of the tray liquid-holding layer in the tower, and the tray's The structure is optimized to obtain the optimization scheme of the tray. This model can accurately obtain the flow characteristics of the tray area and extract the corresponding parameters for the simulation in the tower; for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com