Catalyst for oxygen production through water photolysis and preparation method thereof

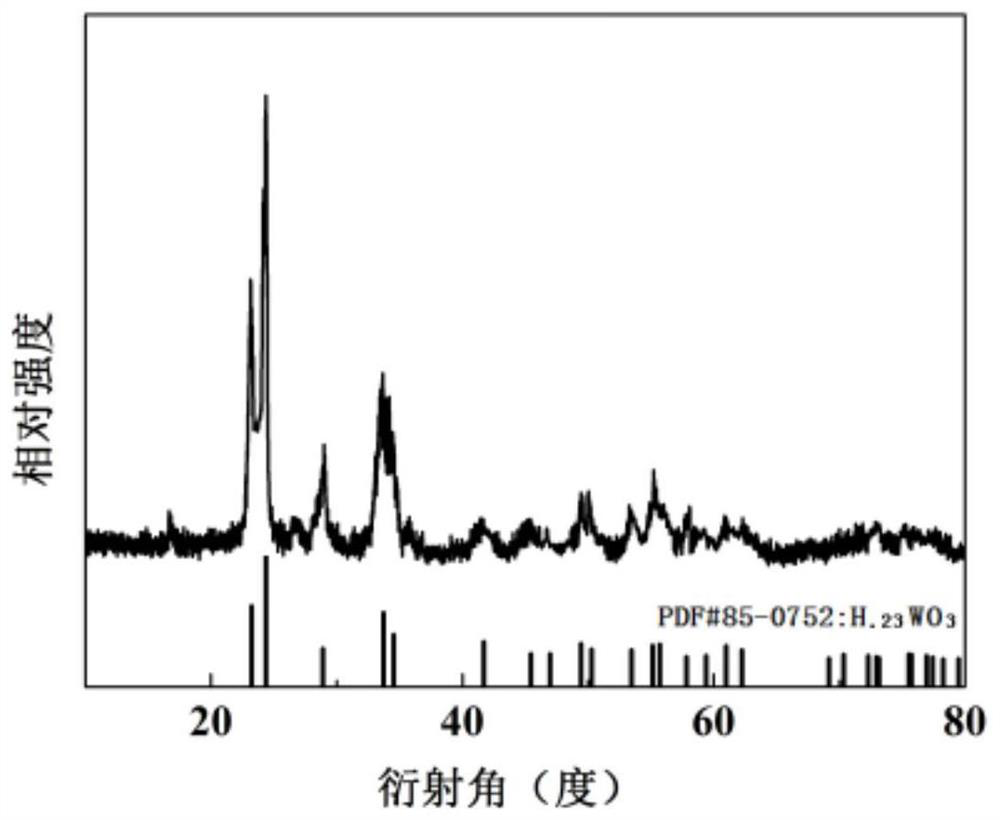

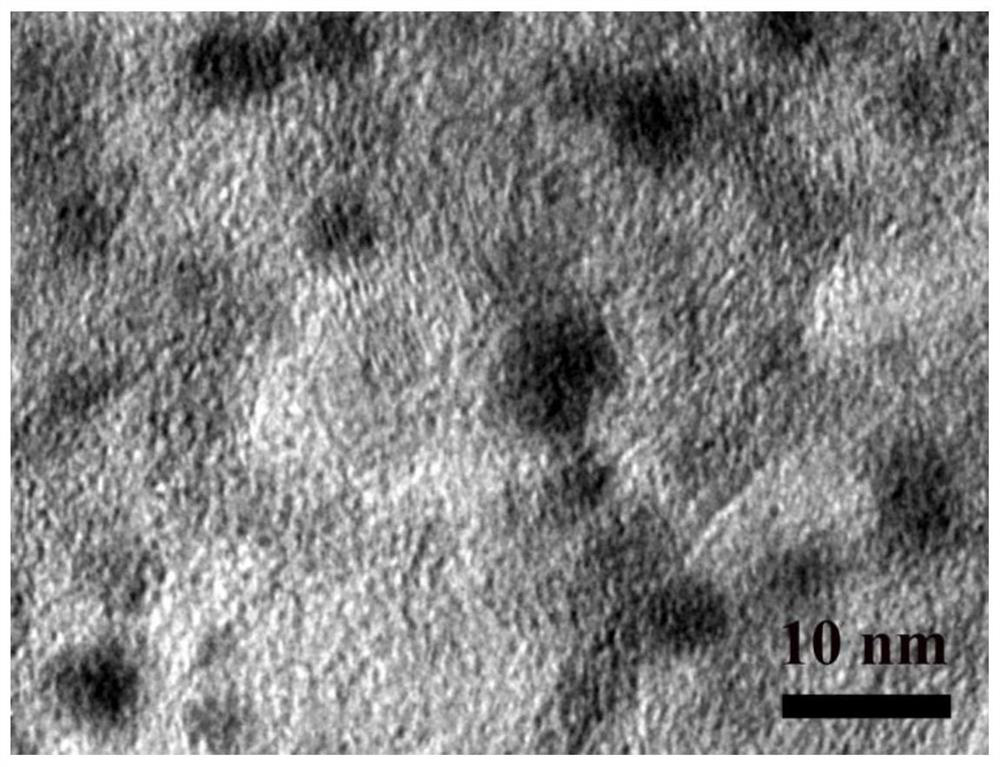

A catalyst, a technology for photolysis of water, applied in the field of preparation of H.23WO3 quantum dots, can solve the problems of harsh experimental conditions, high cost, complex preparation procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: The preparation method of the catalyst for photolysis of water to produce oxygen according to the present embodiment is carried out according to the following steps:

[0034] 1. Preparation of mixed solution: Dissolve 0.36g tungsten chloride in 15mL deionized water to obtain tungsten chloride solution; dissolve 0.17g hydroquinone in 20mL ethanol to obtain hydroquinone solution; The hydroquinone solution was mixed, stirred at room temperature for 10 minutes, then 0.29 g of citric acid was added, and stirred for 30 minutes to obtain a mixed solution;

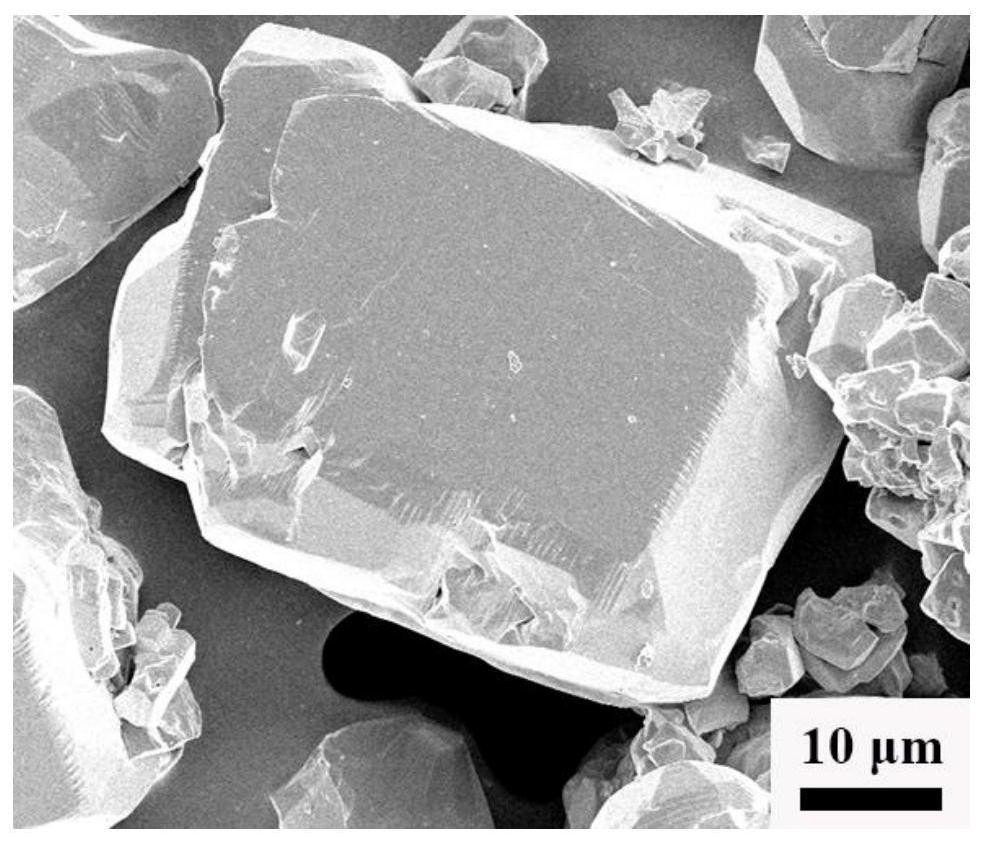

[0035] 2. Preparation of hydrated tungsten trioxide block: transfer the mixed solution to a 50 ml polytetrafluoroethylene autoclave, and put the polytetrafluoroethylene autoclave into an electric heating constant temperature blast drying oven with a temperature of 120°C for 15 hours; then centrifuge the reacted solution, rinse the solid phase with absolute ethanol and distilled water successively, and dry at 8...

Embodiment 2

[0045] Embodiment 2: The preparation method of the catalyst for photolysis of water to produce oxygen according to the present embodiment is carried out according to the following steps:

[0046] 1. Preparation of mixed solution: Dissolve 0.36g tungsten chloride in 15mL deionized water to obtain tungsten chloride solution; dissolve 0.14g phenol in 20mL ethanol to obtain phenol solution; mix tungsten chloride solution and phenol solution, Stir for 10min, then add 0.39g of sodium citrate, stir for 30min to obtain a mixed solution;

[0047] 2. Preparation of hydrated tungsten trioxide block: transfer the mixed solution to a 50 ml polytetrafluoroethylene autoclave, put the polytetrafluoroethylene autoclave into an electric heating constant temperature blast drying oven with a temperature of 140°C for 14 hours; then centrifuge the reacted solution, rinse the solid phase with absolute ethanol and distilled water successively, and dry at 90°C for 12 hours to obtain a hydrated tungste...

Embodiment 3

[0051] Embodiment 3: The preparation method of the catalyst for photolysis of water to produce oxygen according to the present embodiment is carried out according to the following steps:

[0052] 1. Preparation of mixed solution: Dissolve 0.36g tungsten chloride in 15mL deionized water to obtain tungsten chloride solution; dissolve 0.17g catechol in 20mL ethanol to obtain catechol solution; mix tungsten chloride solution with Hydroquinone solution was mixed, stirred at room temperature for 10 minutes, then 0.09 g of urea was added, and stirred for 30 minutes to obtain a mixed solution;

[0053] 2. Preparation of hydrated tungsten trioxide block: transfer the mixed solution to a 50 ml polytetrafluoroethylene autoclave, and put the polytetrafluoroethylene autoclave into an electric heating constant temperature blast drying oven with a temperature of 160°C for 13 hours; then centrifuge the reacted solution, rinse the solid phase with absolute ethanol and distilled water successiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com