Fiber metal laminate composite material and preparation method thereof

A technology of fiber metal laminates and composite materials, applied in the direction of metal layered products, chemical instruments and methods, lamination, etc., can solve the problems of reducing the porosity of laminates in the molding process, shorten the preparation time, and improve the interface bonding The effect of strength and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

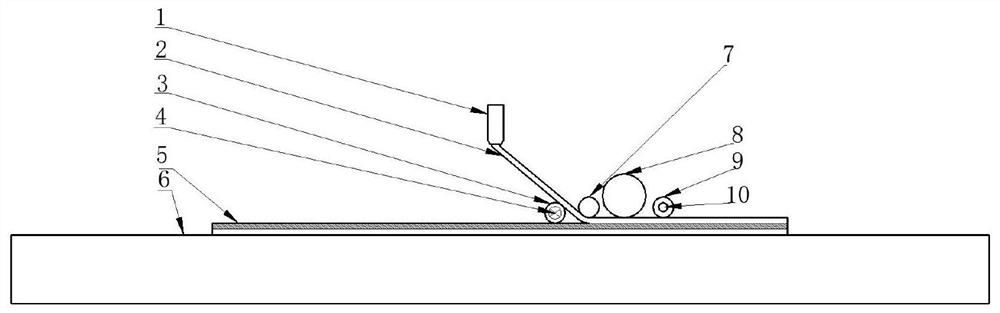

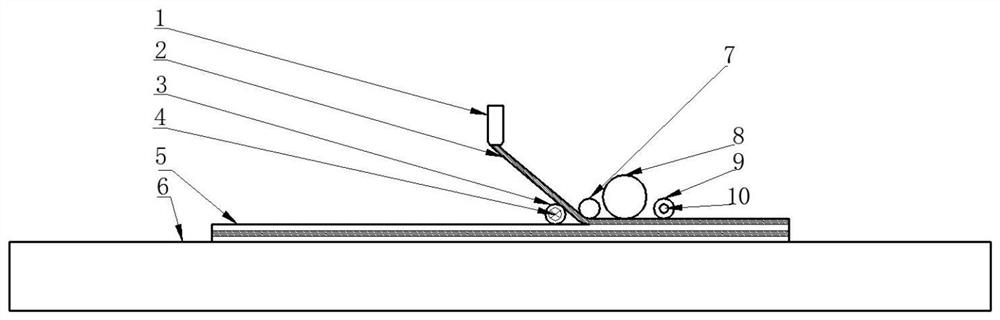

[0059] The invention provides a fiber metal laminate composite material and a preparation method thereof. Firstly, the metal plate is anodized, and the metal sheet and the thermoplastic composite material prepreg are laid alternately, and then the high-power push-pull The ultrasonic generator performs ultrasonic treatment on the fiber metal laminate for a certain period of time. On the one hand, it helps to eliminate the tiny bubbles inside the resin and reduce the porosity. strength. Finally, cooling and forming laminate products are carried out. The process mainly includes the steps of surface treatment of metal sheets, lamination, preheating, ultrasonic treatment, pressurization, and cooling.

[0060] Such as Figure 4 As shown, the above-mentioned thermoplastic fiber metal laminate preparation process specifically includes the following steps:

[0061] 1) Metal sheet surface treatment: the metal sheet is sequentially degreased, pickled, anodized, and primer sprayed.

...

Embodiment 1

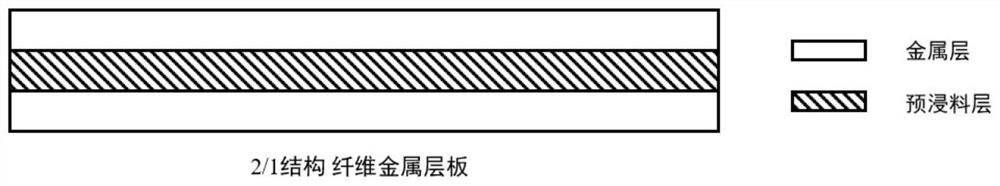

[0071] The metal plate used in Example 1 of the present invention is an aluminum alloy (2024) thin plate, and the thermoplastic composite material is glass fiber-reinforced polyphenylene sulfide (GF / PPS) prepreg, and the fiber is braided. A 2 / 1 or 3 / 2 ply structure is adopted, that is, a layer of GF / PPS prepreg is added between two layers of aluminum alloy sheets.

[0072] Concretely consists of the following steps:

[0073] 1. The aluminum alloy surface treatment process is as follows:

[0074] a) Preliminary preparation: wipe off the oil on the surface of the test piece with absolute alcohol or acetone;

[0075] b) Alkali cleaning: wash with alkaline washing solution at a temperature of 60°C for 90s;

[0076] c) Rinse: Rinse in overflowing clean tap water for 2 minutes;

[0077] d) Acid cleaning: pickle the test piece in the pickling solution for 3 minutes;

[0078] e) Rinsing: Rinse in overflowing tap water for at least 5 minutes;

[0079] f) Phosphoric acid anodizatio...

Embodiment 2

[0093] The difference between embodiment 2 and embodiment 1 is that the glass fiber reinforced polyphenylene sulfide resin layer used is a laminate of alternately arranged glass fibers and polyphenylene sulfide films. When preparing the laminate, the aluminum alloy sheet, glass fiber and thermoplastic resin (polyphenylene sulfide) film are laminated alternately. In step 2, increase the thermoplastic resin film layering process: keep the pressure applied by the indenter at 0.1MPa during the laying process; start the high-power push-pull ultrasonic generation controller with a frequency of 20kHz and an amplitude of 40μm, laying according to the design In the laying direction, the thermoplastic resin film and the underlying material are laid together.

[0094] At the same time, the pressure applied to the metal layer is 1MPa, so as to realize the full infiltration of the glass fiber by the polyphenylene sulfide resin. Other processes and process conditions are the same as in Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com