Manufacturing method and formula of antique tile

A production method and technology of formula, applied in the field of building ceramics, can solve the problems of unfavorable large-scale production, high production cost and high antique cost, and achieve the effects of being beneficial to waste utilization, reducing production cost and improving antique effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A formula for antique tiles, the formula includes: kaolin, coal slag, industrial alumina, potassium feldspar, albite, cement, graphite, quartz, diatomaceous earth, iron oxide, copper oxide and gypsum powder, each component The parts by weight are: 70-80 parts of kaolin, 30-40 parts of coal slag, 5-10 parts of industrial alumina, 5-10 parts of potassium feldspar, 6-8 parts of albite, 7- 10 parts of cement, 4-7 parts of graphite, 15-20 parts of quartz, 15-25 parts of diatomaceous earth, 1-1.5 parts of iron oxide, 0.5-1 part of copper oxide and 5-10 parts of gypsum pink.

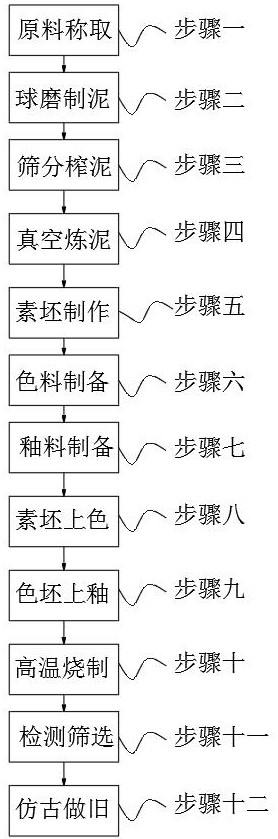

[0036] A method for making an antique tile, comprising the following steps: step 1, weighing raw materials; step 2, ball milling to make mud; step 3, screening and squeezing the mud; step 4, vacuum mud refining; step 5, making biscuit; step 6 , color preparation; step seven, glaze preparation; step eight, coloring the green body; step nine, glaze the color body; step ten, high-temperature firing; step e...

Embodiment 2

[0050] A formula for antique tiles, the formula includes: kaolin, coal slag, industrial alumina, potassium feldspar, albite, cement, graphite, quartz, diatomaceous earth, iron oxide, copper oxide and gypsum powder, each component The parts by weight are: 70-80 parts of kaolin, 30-40 parts of coal slag, 5-10 parts of industrial alumina, 5-10 parts of potassium feldspar, 6-8 parts of albite, 7- 10 parts of cement, 4-7 parts of graphite, 15-20 parts of quartz, 15-25 parts of diatomaceous earth, 1-1.5 parts of iron oxide, 0.5-1 part of copper oxide and 5-10 parts of gypsum pink.

[0051] A method for making an antique tile, comprising the following steps: step 1, weighing raw materials; step 2, ball milling to make mud; step 3, screening and squeezing the mud; step 4, vacuum mud refining; step 5, making biscuit; step 6 , color preparation; step seven, glaze preparation; step eight, coloring the green body; step nine, glaze the color body; step ten, high-temperature firing; step e...

Embodiment 3

[0065] A formula for antique tiles, the formula includes: kaolin, coal slag, industrial alumina, potassium feldspar, albite, cement, graphite, quartz, diatomaceous earth, iron oxide, copper oxide and gypsum powder, each component The parts by weight are: 70-80 parts of kaolin, 30-40 parts of coal slag, 5-10 parts of industrial alumina, 5-10 parts of potassium feldspar, 6-8 parts of albite, 7- 10 parts of cement, 4-7 parts of graphite, 15-20 parts of quartz, 15-25 parts of diatomaceous earth, 1-1.5 parts of iron oxide, 0.5-1 part of copper oxide and 5-10 parts of gypsum pink.

[0066] A method for making an antique tile, comprising the following steps: step 1, weighing raw materials; step 2, ball milling to make mud; step 3, screening and squeezing the mud; step 4, vacuum mud refining; step 5, making biscuit; step 6 , color preparation; step seven, glaze preparation; step eight, coloring the green body; step nine, glaze the color body; step ten, high-temperature firing; step e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com