Modified inorganic silicate compounded stain-resistant anti-freezing emulsion and preparation method thereof

An inorganic silicate and modification technology, applied in the field of emulsion, can solve the problems of difficult to take into account the pollution resistance, excellent anti-freeze stability and low stability at the same time, achieve excellent anti-fouling performance and anti-freezing stability, solve the problem of high VOC content, The effect of excellent antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a method for preparing the above-mentioned modified inorganic silicate composite anti-frost emulsion, comprising the following steps:

[0065] Step S100, preparing prepolymer seeds: when the temperature in the reactor reaches 35-40°C, quickly pour the monomer emulsion A and initiator solution A into the reactor with the bottom liquid, and then lower the temperature in the reactor to Slowly raise the temperature to 83-85°C and keep it warm for 30 minutes to prepare prepolymer seeds;

[0066] In this step, prepolymer seeds with fine particle size and low glass transition temperature are first initiated and polymerized at low temperature, which can ensure a more uniform particle size distribution of the final emulsion and ensure the pollution and anti-fouling properties of the modified inorganic silicate compound. the quality of frozen emulsions;

[0067] Step S200, preparation of core-shell polymer emulsion: After the prepolymer seeds ...

Embodiment 1

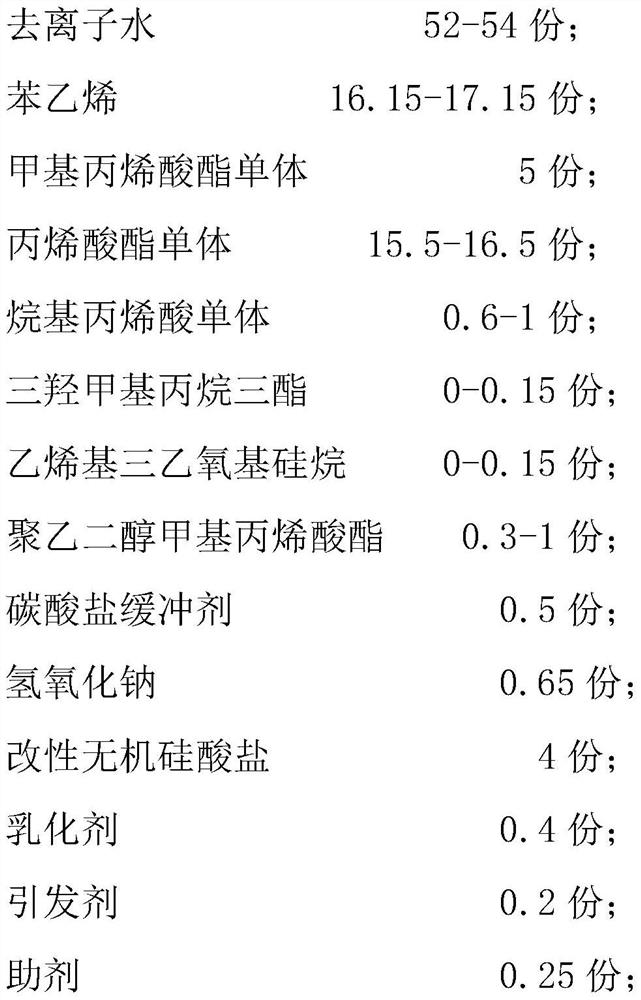

[0088] The invention provides a modified inorganic silicate composite anti-fouling and antifreeze emulsion, the raw materials of which include the following components by weight:

[0089]

[0090]

[0091] Further, the present invention also provides a method for preparing the above-mentioned modified inorganic silicate composite anti-fouling and antifreeze emulsion, comprising the following steps:

[0092] Step S100, preparing prepolymer seeds: when the temperature in the reactor reaches 35°C, quickly pour the monomer emulsion A and initiator solution A into the reactor with the bottom liquid, and then slowly raise the temperature in the reactor To 83 ℃, heat preservation for 30 minutes to prepare prepolymer seeds;

[0093] Step S200, preparation of core-shell polymer emulsion: After the prepolymer seeds are obtained, the constant flow dripping pump is turned on at the same time, and the monomer emulsion B and the initiator solution B are respectively added dropwise into ...

Embodiment 2

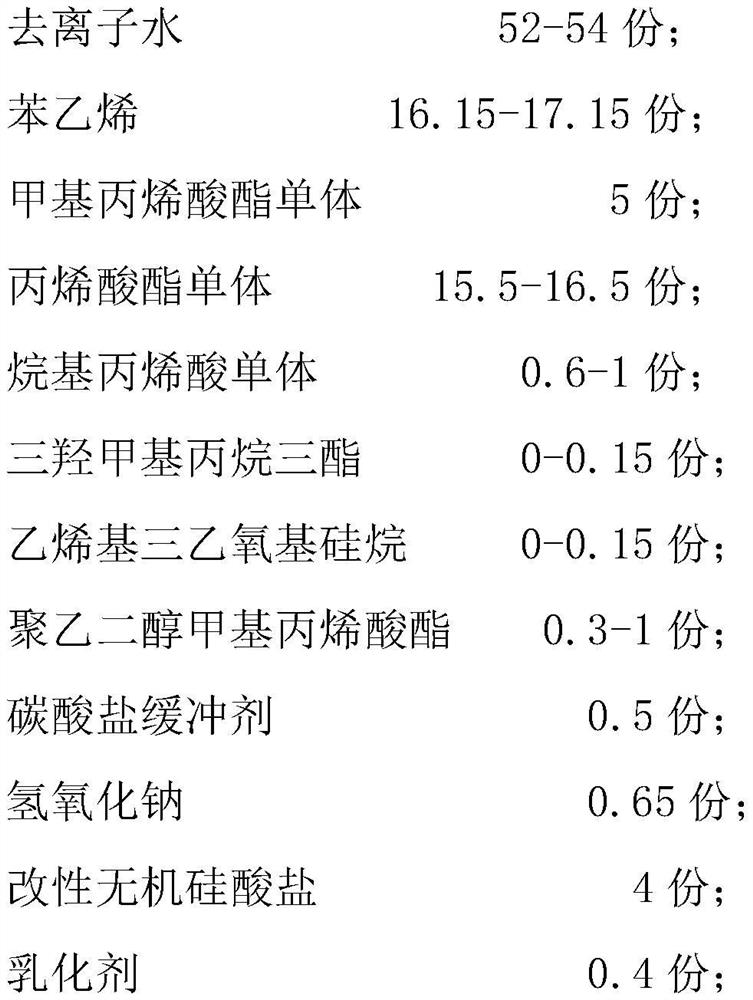

[0110] The invention provides a modified inorganic silicate composite anti-fouling and antifreeze emulsion, the raw materials of which include the following components by weight:

[0111]

[0112]

[0113] Further, the present invention also provides a method for preparing the above-mentioned modified inorganic silicate composite anti-fouling and antifreeze emulsion, comprising the following steps:

[0114] Step S100, preparing prepolymer seeds; when the temperature in the reactor reaches 36°C, quickly pour monomer emulsion A and initiator solution A into the reactor equipped with bottom liquid, and then slowly raise the temperature in the reactor To 84 ℃, heat preservation for 30 minutes to prepare prepolymer seeds;

[0115] Step S200, preparation of core-shell polymer emulsion: After the prepolymer seeds are obtained, the constant flow dripping pump is turned on at the same time, and the monomer emulsion B and the initiator solution B are respectively added dropwise in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com