Solid-waste-based alkali-activated cementing road building material, preparation method and road building method

A technology of alkali excitation and gelling, which is applied in roads, roads, buildings, etc., can solve the problems of long-term use of heavy-duty roads in open-pit mines, unsuitable for large-scale promotion, high production costs, etc., and achieve the elimination of traffic Hidden dangers of accidents, improvement of road strength and smoothness, and the effect of improving road quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

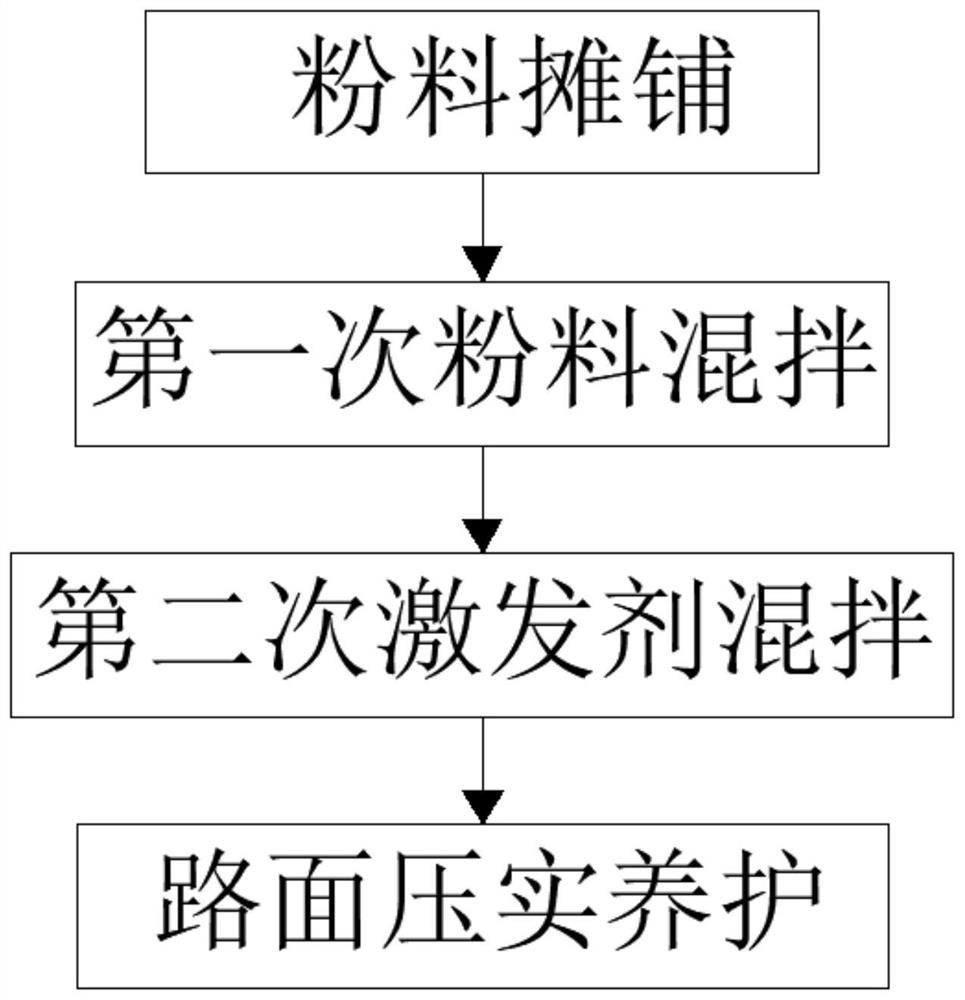

Method used

Image

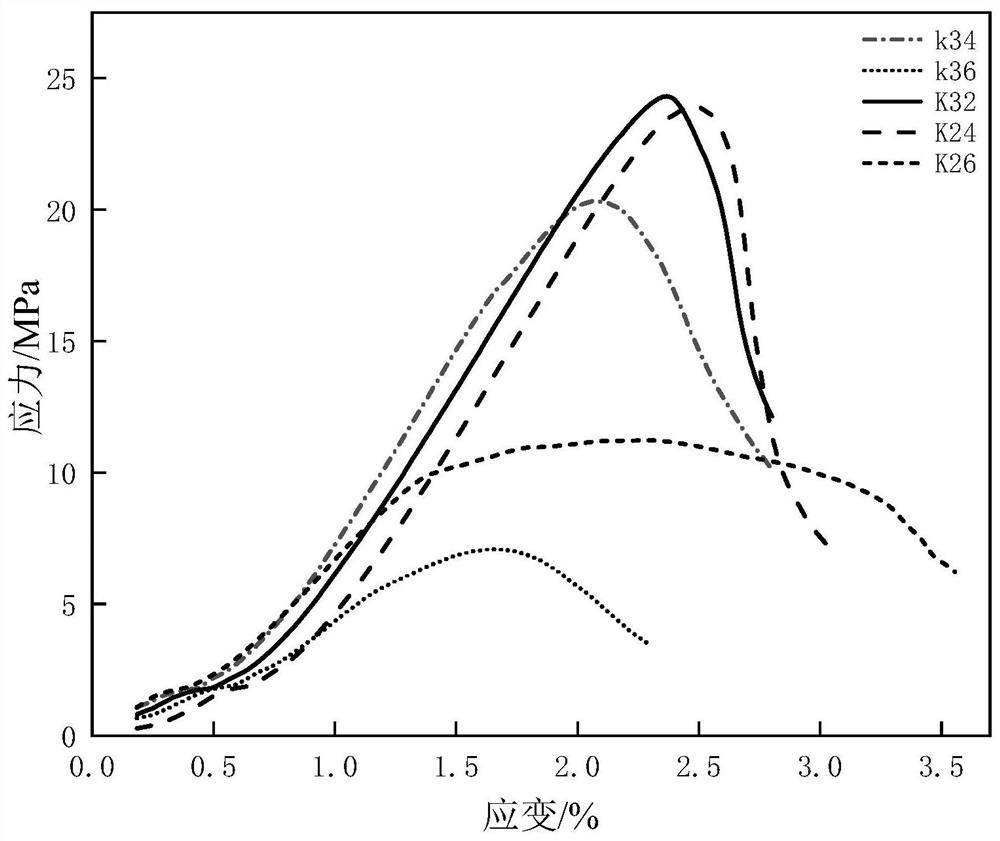

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below.

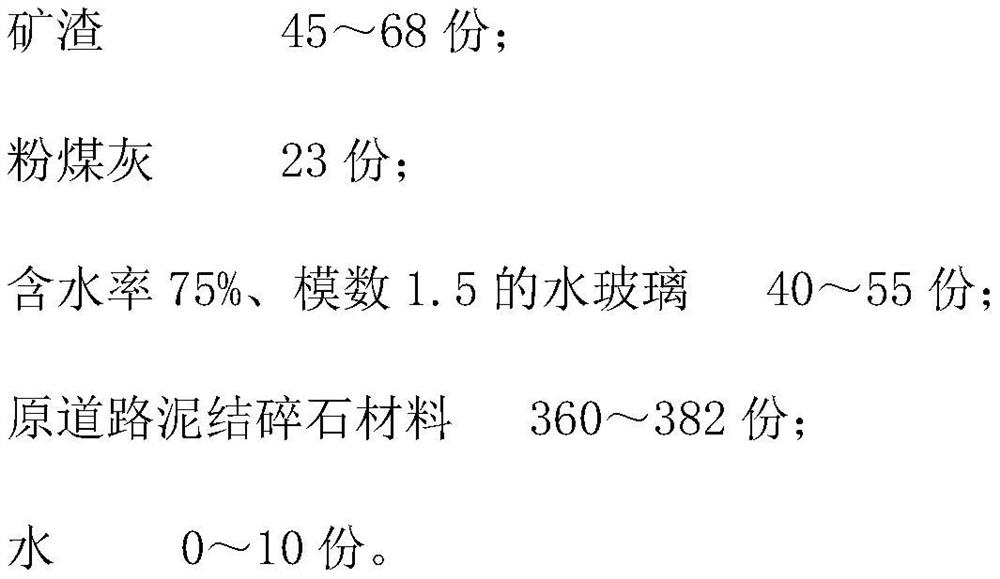

[0032] The present invention provides a kind of solid waste alkali-activated gelled road construction material, which is characterized in that it comprises the following raw materials in parts by mass:

[0033]

[0034] as a preference;

[0035]

[0036] In order to ensure the reliability of the performance of the road construction material, the fly ash is a first-grade fly ash; the original road material is a solid particle of 0.1 mm to 50 mm.

[0037] As a preference, the water glass is liquid sodium silicate.

[0038] The main raw material of the road construction material is industrial waste residue, which has low cost and good environmental protection performance, and at the same time, its sources are extensive and unlimited. The original road mud-bound crushed stone material in the road construction material is the target reconstruction material, and it is also the aggregate part of the roa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com