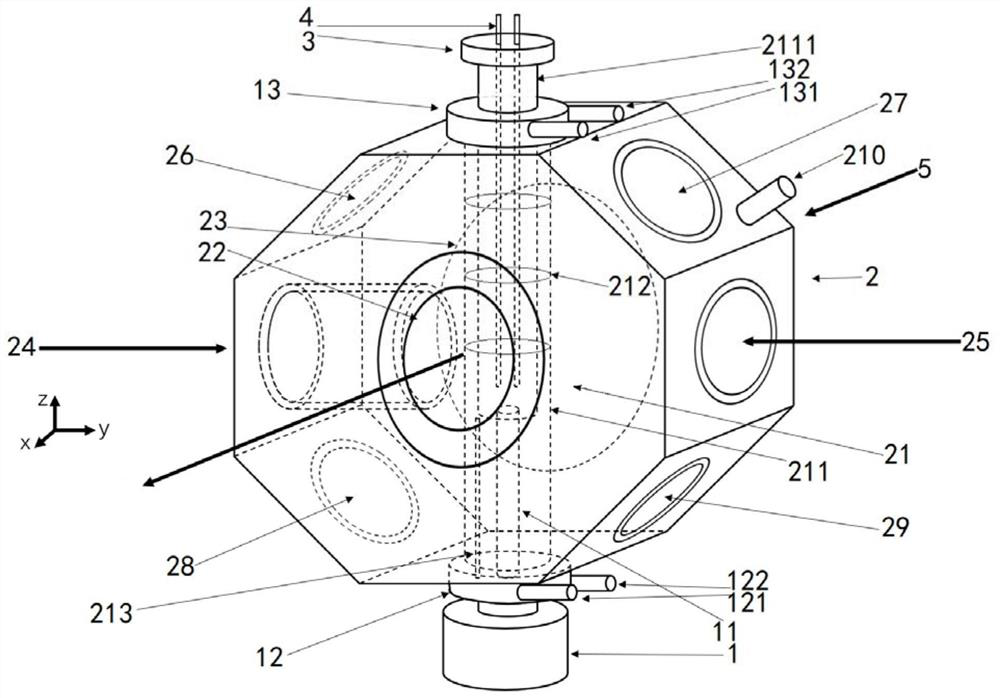

Molten salt electrochemical multifunctional in-situ characterization device and use method

An electrochemical and multifunctional technology, applied in the direction of material electrochemical variables, measuring devices, and material analysis using radiation, can solve problems such as hysteresis, inability to achieve real-time acquisition of various information, and difficulty in direct observation of the electrolysis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A method for using a molten salt electrochemical multifunctional in-situ characterization device, the specific steps are as follows;

[0077] Step 1: Take an equimolar ratio of NaCl and KCl molten salt mixture and place it in a transparent electrolytic cell 2111 with an outer diameter of 10 mm and a wall thickness of 1 mm, place the transparent electrolytic cell 2111 in the optically transparent hearth 211 of the vacuum holding furnace 2 and combine The rotary table 1 is tightly connected; the transparent electrolytic cell 2111 is a quartz tube;

[0078] Step 2: When the vacuum holding furnace 2 is evacuated to 1-10Pa, start to increase the temperature of the transparent electrolytic cell 2111 until the molten salt mixture in the transparent electrolytic cell 2111 is melted and kept at 700°C to obtain a high-temperature melt;

[0079] Step 3: Insert two graphite electrodes into the high-temperature melt by operating the furnace cover 3 and the electrode system 4, and th...

Embodiment 2

[0083] A method for using a molten salt electrochemical multifunctional in-situ characterization device, the specific steps are as follows;

[0084] Step 1: Take Na with a molar ratio of 3:2 2 CO 3 and K 2 CO 3 The molten salt mixture is placed in a transparent electrolytic cell 2111 with an outer diameter of 10 mm and a wall thickness of 1 mm, and the transparent electrolytic cell 2111 is placed in the optically transparent hearth 211 of the vacuum holding furnace 2 and is closely connected with the rotary table 1; the transparent electrolytic cell 2111 is a quartz tube;

[0085] Step 2: When the vacuum holding furnace 2 is evacuated to 1-10 Pa, start to increase the temperature of the transparent electrolytic cell 2111 until the molten salt mixture in the transparent electrolytic cell 2111 is melted and kept at 800°C to obtain a high-temperature melt;

[0086] Step 3: Insert two graphite electrodes into the high-temperature melt by operating the furnace cover 3 and the e...

Embodiment 3

[0090] A method for using a molten salt electrochemical multifunctional in-situ characterization device, the specific steps are as follows;

[0091] Step 1: Take NaCl and AlCl in equimolar ratio 3 The molten salt mixture is placed in a transparent electrolytic cell 2111 with an outer diameter of 10 mm and a wall thickness of 1 mm. The transparent electrolytic cell 2111 is placed in the optically transparent hearth 211 of the vacuum holding furnace 2. There is a glass support rod at the bottom of the transparent electrolytic cell 2111 , the support rod can be directly fixed to the bottom rotary table 1 by mechanical clamping; the transparent electrolytic cell 2111 is a glass tube;

[0092] Step 2: When the vacuum holding furnace 2 is evacuated to 1-10Pa, start to increase the temperature of the transparent electrolytic cell 2111 until the molten salt mixture in the transparent electrolytic cell 2111 is heated to 150°C and kept warm;

[0093]Step 3: insert sheet-shaped metal al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com