Preparation method of edible betel nuts capable of reducing betel nut fiber strength

A fiber strength, betel nut technology, applied in application, food drying, food science and other directions, can solve the problems of increasing oral mucosal leukoplakia, oral irritation, etc., and achieve the effect of shortening the cooking time, easy to chew and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

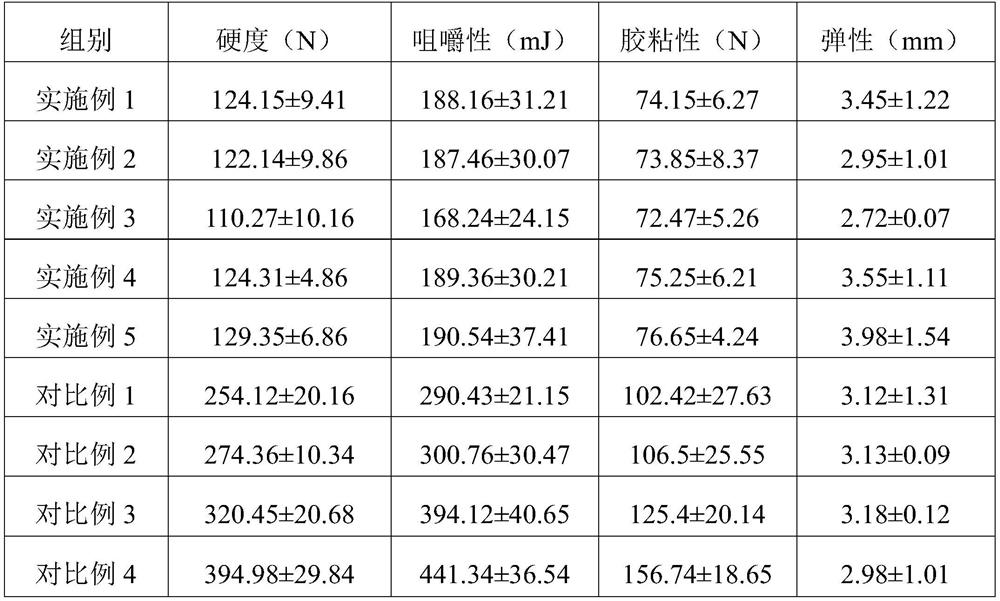

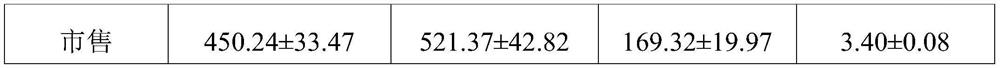

Examples

Embodiment 1

[0022] A preparation method of edible betel nut that reduces betel nut fiber strength:

[0023] S1, the preparation of bittern: comprise the following raw materials in parts by weight: 20 parts of caramel, 7 parts of calcium hydroxide, 6 parts of gelatin, 16 parts of coconut oil, 5 parts of chitosan, 12 parts of Coriander leaf essential oil, 8 parts of rosemary essential oil, 11 parts of clam essential oil, 2 parts of sweetener;

[0024] S2, boil the seeds and fix the greens: choose the betel nut seeds that are full and free of pests and diseases, and cook them in 60°C water for 4 minutes after cleaning;

[0025] S3, ultra-high pressure treatment: the betel nut after the greening is subjected to ultra-high pressure treatment for 1min under the pressure of 300MPa, and then dried and processed;

[0026] S4. Slicing and drying: The processed betel nut is then dried at 50°C for 35 minutes and then sliced and seeded. The slicing is to cut the whole betel nut into quarters vertic...

Embodiment 2

[0032] A preparation method of edible betel nut that reduces betel nut fiber strength:

[0033] S1, the preparation of bittern: comprise the following raw materials in parts by weight: 20 parts of caramel, 7 parts of calcium hydroxide, 6 parts of gelatin, 16 parts of coconut oil, 5 parts of chitosan, 12 parts of Coriander leaf essential oil, 8 parts of rosemary essential oil, 11 parts of clam essential oil, 2 parts of sweetener;

[0034] S2. Boil the seeds and fix the greens: Choose betel nut seeds that are full and free of diseases and insect pests, and cook them in 80°C water for 8 minutes after cleaning;

[0035] S3, ultra-high pressure treatment: the betel nut after the greening is subjected to ultra-high pressure treatment for 10min under the pressure of 600MPa, and then dried and processed;

[0036] S4. Dry slices: The processed betel nut is then dried at 60°C for 45 minutes, sliced and seeded. The slice is to cut the whole betel nut into quarters vertically.

[0037...

Embodiment 3

[0042] A preparation method of edible betel nut that reduces betel nut fiber strength:

[0043] S1, the preparation of bittern: comprise the following raw materials in parts by weight: 20 parts of caramel, 7 parts of calcium hydroxide, 6 parts of gelatin, 16 parts of coconut oil, 5 parts of chitosan, 12 parts of Coriander leaf essential oil, 8 parts of rosemary essential oil, 11 parts of clam essential oil, 2 parts of sweetener;

[0044] S2, boil the seeds and fix the greens: choose full, disease-free betel nut seeds, and cook them in 70°C water for 6 minutes after cleaning;

[0045] S3, ultra-high pressure treatment: the betel nut after the greening is subjected to ultra-high pressure treatment for 5min under the pressure of 400MPa, and then dried and processed;

[0046] S4. Dried slices: The processed betel nut is then dried at 55°C for 40min, sliced and seeded. The slice is to cut the whole betel nut into quarters vertically.

[0047] S5, point brine: point brine on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com