Method for modifying red mud and method for decoking and desulfurizing in organic solid waste pyrolysis gasification process

A technology of organic solid waste, pyrolysis gasification, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as water and soil pollution, red mud metal waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

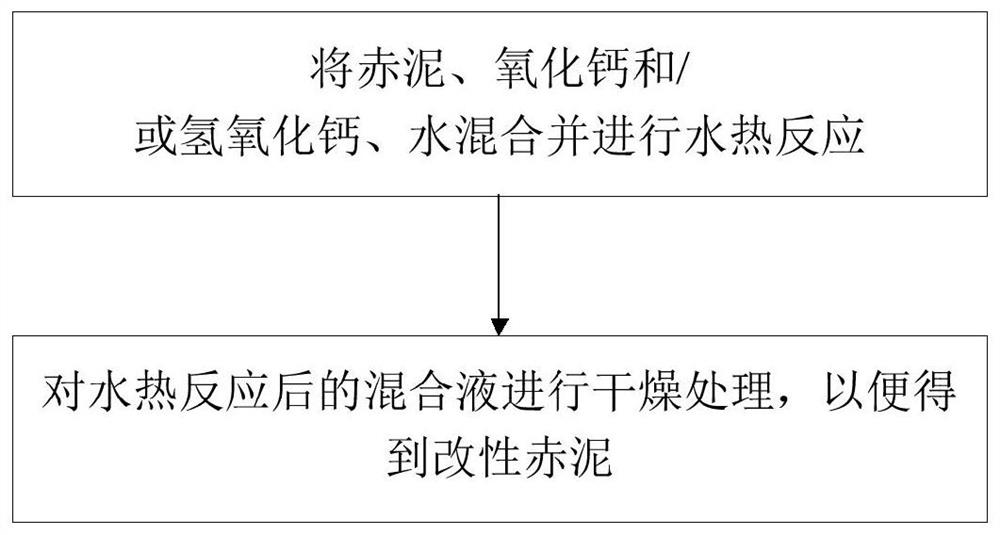

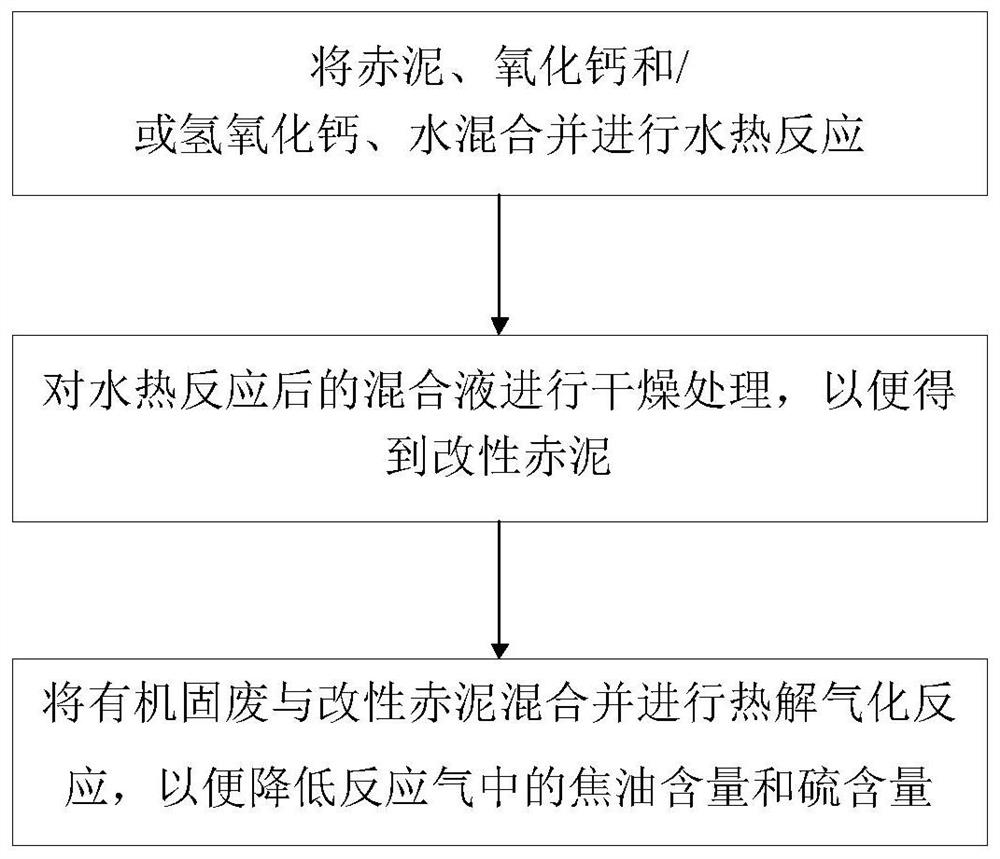

Method used

Image

Examples

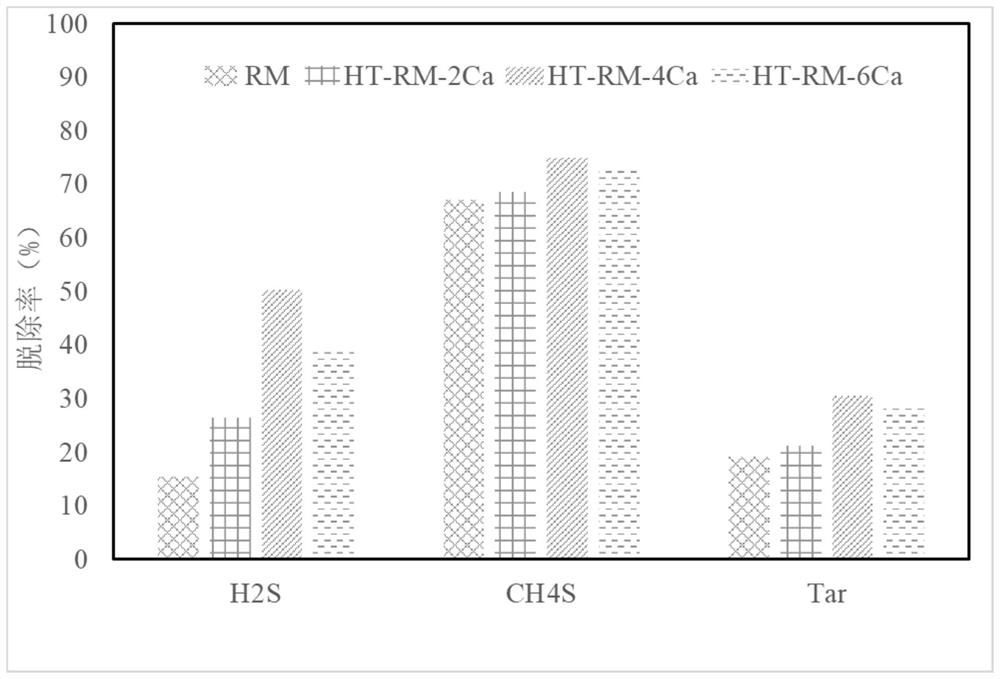

Embodiment 1

[0051] 1) The method of modifying red mud includes: weighing 5g of dry red mud powder and placing it in a 100mL beaker, according to the molar content of sodium in the red mud, accurately weigh 1.024g of Add calcium oxide into the beaker, pour 60.2mL deionized water into the beaker according to the solid-to-liquid mass ratio of 1:10, place the beaker containing the mixture of red mud and calcium oxide on a magnetic stirrer, and stir at 100r / min , fully stirred for 30 minutes; then pour the uniformly mixed suspension into a hydrothermal reaction kettle, and put the sealed reaction kettle in an oven at 80°C for 24 hours; then pour the hydrothermally treated product into the rotary evaporator Vacuum drying is carried out in the evaporating flask, the drying temperature is 50°C, and the rotation speed is 100r / min; the dried modified red mud is ground and sieved into particles with a particle size of less than 63 μm, and the modified red mud obtained through this process is named HT...

Embodiment 2

[0056] 1) The method of modifying red mud includes: weighing 4g of dry red mud powder and placing it in a 100mL beaker, and accurately weighing 1.638g of red mud according to the molar content of sodium in the red mud with a sodium / calcium molar ratio of 1:4 Add calcium oxide into the beaker, pour 58.8mL deionized water into the beaker according to the solid-to-liquid mass ratio of 1:10, place the beaker containing the mixture of red mud and calcium oxide on a magnetic stirrer, and stir at 100r / min , fully stirred for 30 minutes; then pour the uniformly mixed suspension into a hydrothermal reaction kettle, and put the sealed reaction kettle in an oven at 80°C for 24 hours; then pour the hydrothermally treated product into the rotary evaporator Vacuum drying is carried out in the evaporating flask, the drying temperature is 50°C, and the rotation speed is 100r / min; the dried modified red mud is ground and sieved into particles with a particle size of less than 63 μm, and the mod...

Embodiment 3

[0059] 1) The method of modifying red mud includes: weighing 3.5g of dry red mud powder and placing it in a 100mL beaker. According to the molar content of sodium in the red mud, accurately weigh 2.151g according to the sodium / calcium molar ratio of 1:6 Add calcium oxide into the beaker, pour 56.4mL deionized water into the beaker according to the solid-to-liquid mass ratio of 1:10, place the beaker containing the mixture of red mud and calcium oxide on a magnetic stirrer, and stir at 100r / min speed, fully stirred for 30 minutes; then pour the uniformly mixed suspension into a hydrothermal reaction kettle, put the sealed reaction kettle in an oven at 80°C for 24 hours; then pour the hydrothermally treated product into a rotary evaporator Vacuum drying is carried out in a evaporating flask, the drying temperature is 50°C, and the rotation speed is 100r / min; the dried modified red mud is ground and sieved into particles with a particle size of less than 63 μm, and the modified re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com