A kind of concrete with anti-cracking and frost resistance

A concrete and anti-freezing technology, applied in the field of concrete, can solve the problems of steel surface corrosion, passivation film damage, concrete cracking, etc., and achieve good anti-freezing performance, high anti-cracking performance, and increase weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

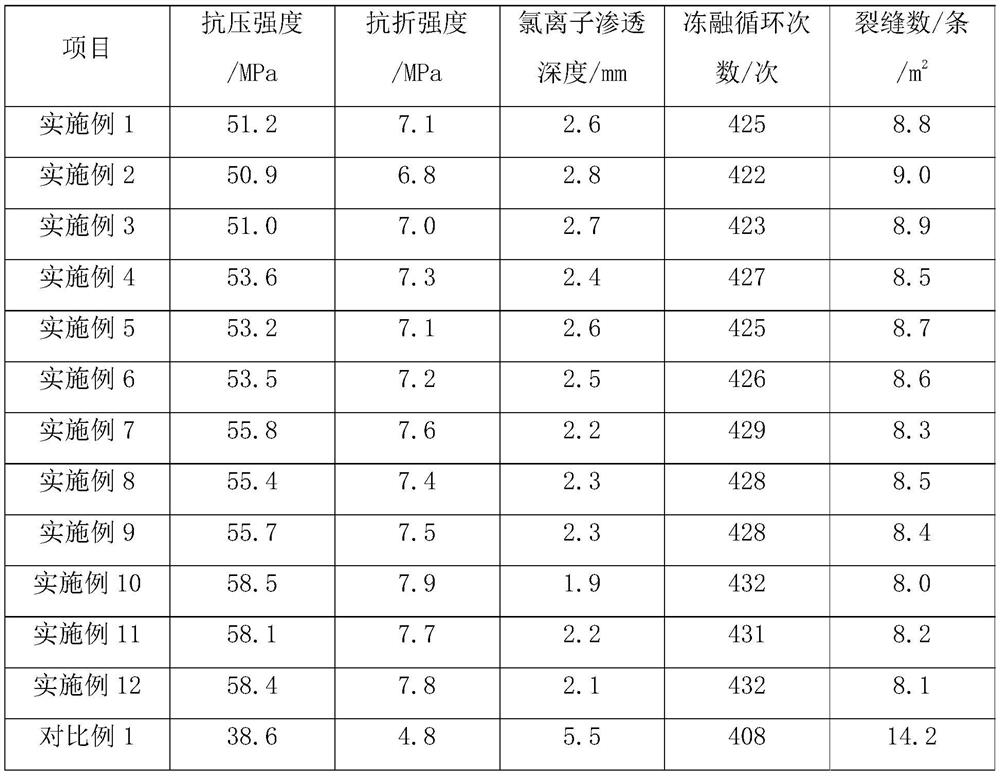

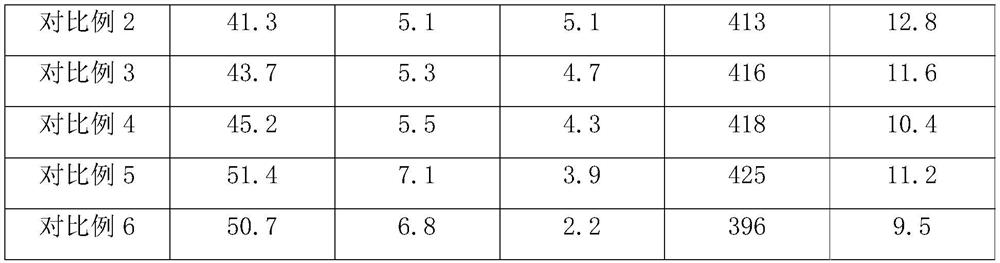

Examples

preparation example 1

[0038] Preparation example 1: Modified asbestos fiber is prepared by the following method:

[0039] ① Weigh 4.5kg of 2-hydroxyethyl acrylate and place it in 55kg of absolute ethanol and stir for 3min at a speed of 550r / min to obtain a mixed solution;

[0040] ② Weigh 45kg of asbestos fibers and dry them at 55°C for 20 minutes, place the dried asbestos fibers in an irradiation container, then add the mixture prepared in ①, press the cap with a film with small holes, and pump Vacuum, after vacuum degassing, rush into nitrogen, seal and place on the oscillator, use JJ-2 type electron electrostatic accelerator to irradiate, the electron beam energy is 1.7MeV, and the irradiation time is 30min, and the modified asbestos fiber is obtained .

preparation example 2

[0041] Preparation example 2: Modified asbestos fiber is prepared by the following method:

[0042] ① Weigh 2kg of 2-hydroxyethyl acrylate and place it in 45kg of absolute ethanol and stir for 3min at a speed of 550r / min to obtain a mixed solution;

[0043] ②Weigh 35kg of asbestos fibers and dry them at 55°C for 20 minutes, place the dried asbestos fibers in an irradiation container, then add the mixture prepared in ①, cover with a film with small holes, and pump Vacuum, after vacuum degassing, rush into nitrogen, seal and place on the oscillator, use JJ-2 electron electrostatic accelerator to irradiate, the electron beam energy is 1.7MeV, and the irradiation time is 25min, and the modified asbestos fiber is obtained .

preparation example 3

[0044] Preparation example 3: Modified asbestos fiber is prepared by the following method:

[0045] ① Weigh 6kg of 2-hydroxyethyl acrylate and place it in 65kg of absolute ethanol and stir for 3min at a speed of 550r / min to obtain a mixed solution;

[0046] ② Weigh 55kg of asbestos fibers and dry them at 55°C for 20 minutes, place the dried asbestos fibers in an irradiation container, then add the mixture prepared in ①, cover with a film with small holes, and pump Vacuum, after vacuum degassing, rush into nitrogen, seal and place on the oscillator, use JJ-2 type electron electrostatic accelerator to irradiate, the electron beam energy is 1.7MeV, and the irradiation time is 35min, and the modified asbestos fiber is obtained .

[0047] Preparation example of composite fiber

[0048] The polylactic acid fibers in the following raw materials were purchased from polylactic acid staple fibers produced by Shaoxing Xineng Textile Technology Co., Ltd., with a length of 6mm; polyethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com