Polysiloxane composition and application thereof

A technology of polysiloxane and hydrogen polysiloxane, applied in the field of polysiloxane composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of vinyl polysiloxane:

[0041] Formula I-1 It can be synthesized by the following steps:

[0042] (1) Take 0.5g of platinum as a hydrosilylation catalyst, add 5mL of toluene to dilute, and then add it to a 250mL three-necked flask;

[0043] (2) Take 2.49g 1,3,5-triallyl-1,3,5-triazine-2,4,6(1H,3H,5H)-triketone (1,3,5-Triallyl-1 ,3,5-triazine-2,4,6(1H,3H,5H)-trione, molecular weight MW=249.27g / mol), add 20mL of toluene to dilute and add to the three-necked flask;

[0044] (3) Take 28.56g compound containing silicon-hydrogen bond Add 25mL of toluene to dilute and add to the three-necked flask;

[0045] (4) Set the oil bath temperature to 130°C, turn on the stirring, turn on the condensed water, and when the temperature in the three-necked flask is 119°C, the reaction mixture begins to reflux;

[0046] (5) After refluxing for a period of time, draw a small amount of the reaction mixture for IR testing to determine whether the reaction is comp...

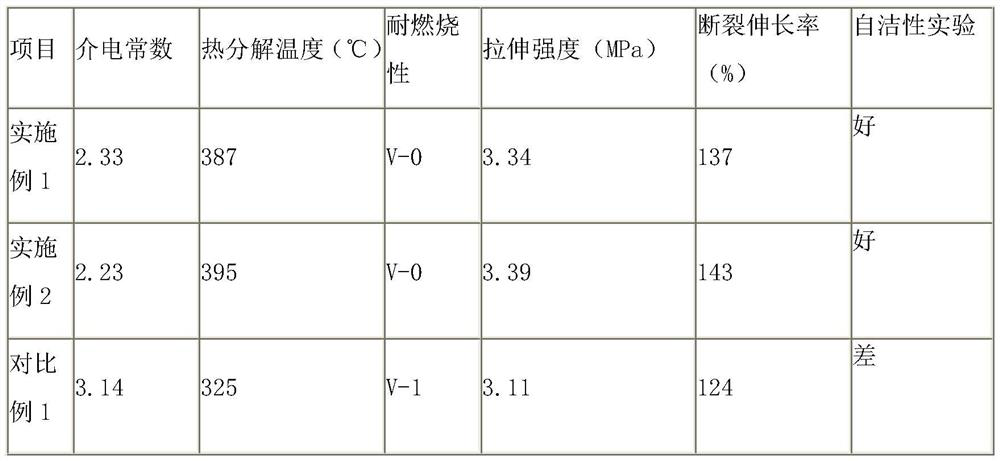

Embodiment 1

[0064] The polysiloxane composition of the present embodiment consists of the following:

[0065] 45 parts vinyl polysiloxane;

[0066] 5 parts gas silicon 1, 5 parts gas silicon 2;

[0067] 10 parts of double-ended hydrogen-containing polysiloxane, 5 parts of side-chain hydrogen-containing silicone oil;

[0068] 10 parts of methylphenyl polysiloxane;

[0069] 3 parts talcum powder;

[0070] 0.5 parts platinum catalyst;

[0071] 1 Inhibitor;

[0072] 0.6 parts curing accelerator.

[0073] Wherein, the preparation technology of above-mentioned composition is as follows:

[0074] (1) In parts by weight, first weigh vinyl polysiloxane, hydrogen-containing silane polymer 1, methylphenyl polysiloxane, and acetylenic alcohol inhibitors into the reactor, and vacuumize to maintain a pressure difference ≥ 0.08MPa, at a temperature of 50°C, stir continuously for 15 minutes;

[0075] (2) Add hydrogen-containing silane polymer 2 on the basis of (1), add in batches, mix for 5 minut...

Embodiment 2

[0080] The polysiloxane composition of the present embodiment consists of the following:

[0081] 50 parts vinyl polysiloxane;

[0082] 10 parts gas silicon 1, 5 parts gas silicon 2;

[0083] 10 parts of double-ended hydrogen-containing polysiloxane, 10 parts of side-chain hydrogen-containing silicone oil;

[0084] 20 parts of methylphenyl polysiloxane;

[0085] 3 parts talcum powder;

[0086] 0.5 parts platinum catalyst;

[0087] 1 Inhibitor;

[0088] 0.6 parts curing accelerator.

[0089] Wherein, the preparation technology of above-mentioned composition is as follows:

[0090] (1) In parts by weight, first weigh vinyl polysiloxane, hydrogen-containing silane polymer 1, methylphenyl polysiloxane, and acetylenic alcohol inhibitors into the reactor, and vacuumize to maintain a pressure difference ≥ 0.08MPa, at a temperature of 50°C, stir continuously for 15 minutes;

[0091] (2) Add hydrogen-containing silane polymer 2 on the basis of (1), add in batches, mix for 5 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com