Polymer flame retardant and preparation method thereof

A flame retardant and polymer technology, which is applied in the field of polymer flame retardants and their preparation, can solve problems such as hindering widespread application, reducing flame retardant durability, and general flame retardant effect, achieving low cost and high flame retardant performance , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

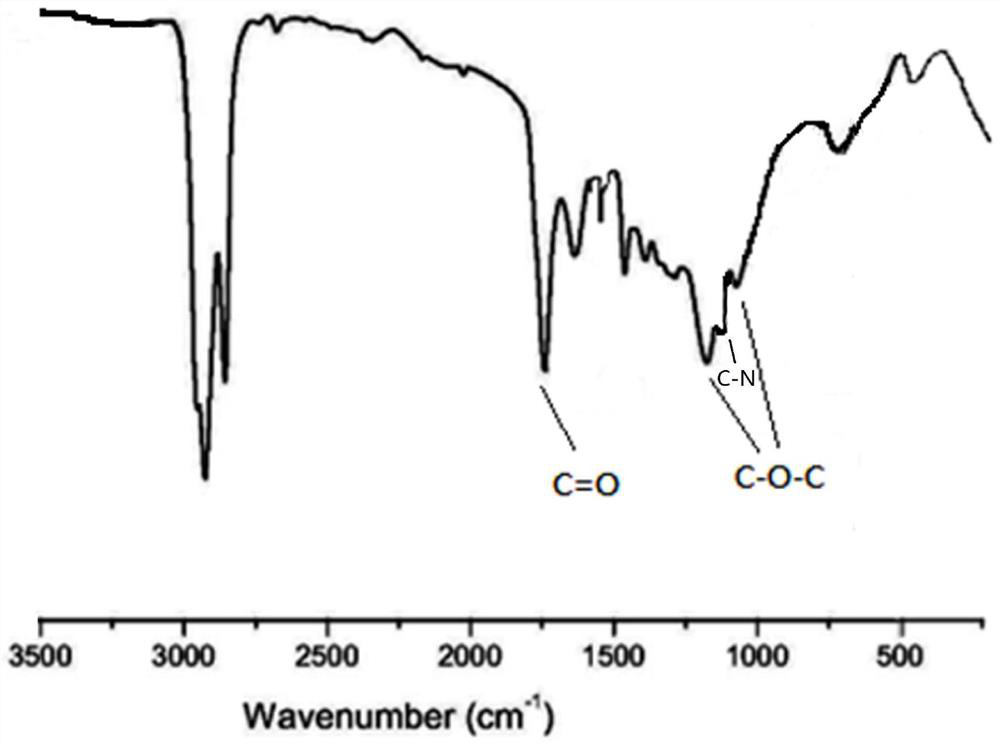

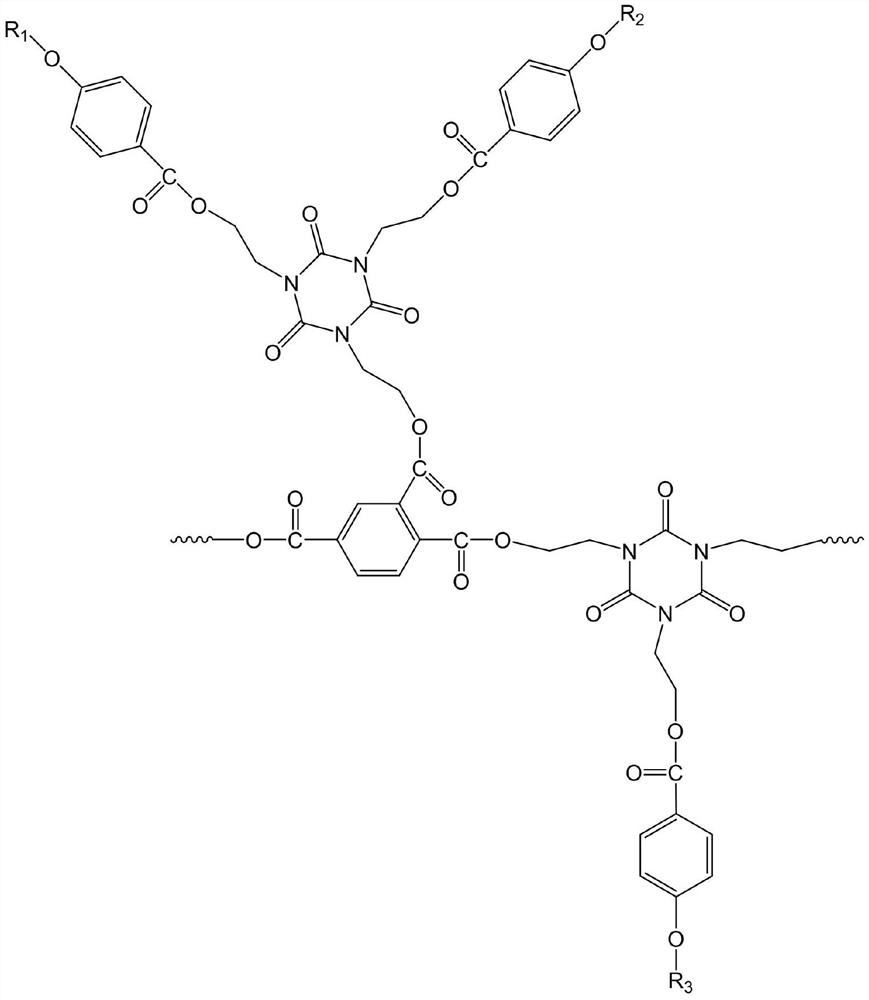

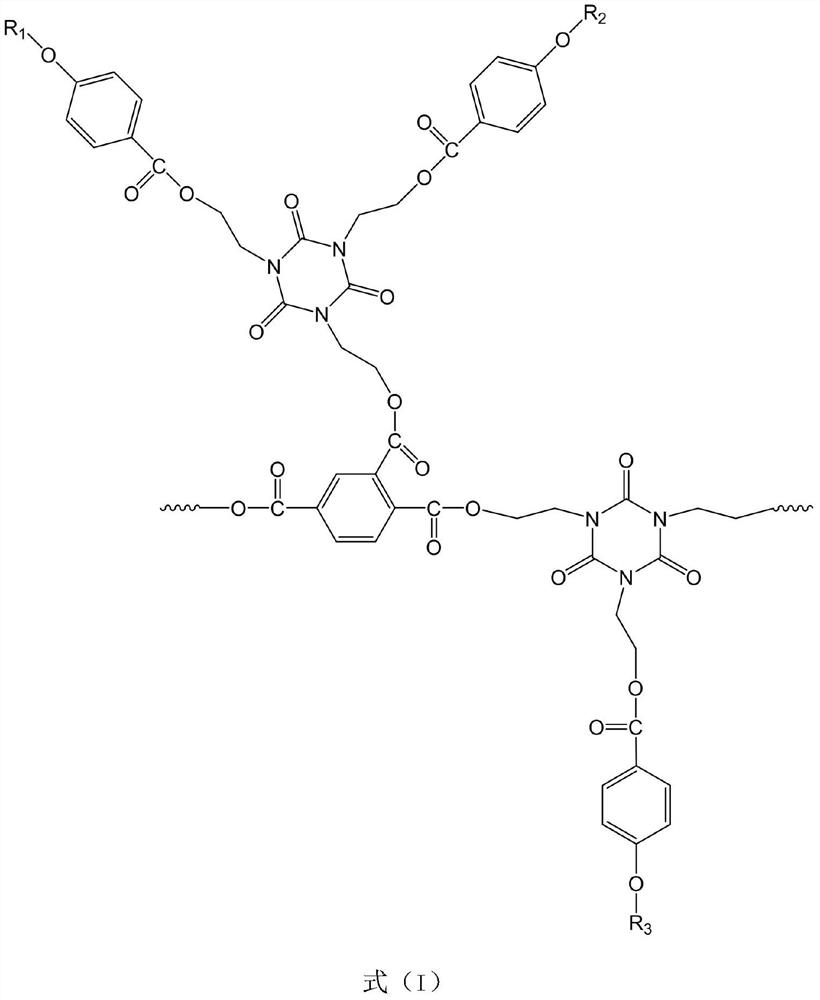

Method used

Image

Examples

Embodiment 1

[0031] 1) Preparation of carboxyl-containing chlorinated paraffin 42: Dissolve 20 g of chlorinated paraffin 42 in 210 mL of acetone, stir to dissolve, add 20 g of p-hydroxybenzoic acid and 28 g of potassium carbonate, and react at 65° C. for 24 h under nitrogen protection. After the reaction, the pH was adjusted to 3.0 with hydrochloric acid, and then extracted with ethanol, and the product was vacuum-dried at 100° C. for 5 h to obtain carboxyl-containing chlorinated paraffin 42.

[0032] 2) Preparation of chlorinated paraffin 42 containing acid chloride: add 70 mol of chlorinated paraffin 42 containing carboxyl group to the reaction kettle, add 85 mol of phosphorus trichloride dropwise, stir and heat up to 50°C, react for 4 hours, cool to room temperature, stand and separate Chlorinated paraffins 42 containing acid chlorides were obtained.

[0033] 3) Preparation of isocyanurate-modified chlorinated paraffin 42 monohydric alcohol: add 100mol tris(2-hydroxyethyl)isocyanurate a...

Embodiment 2

[0038] 1) Preparation of carboxyl-containing chlorinated paraffin 52: Dissolve 20 g of chlorinated paraffin 52 in 220 mL of acetone, stir to dissolve, add 20 g of p-hydroxybenzoic acid and 29 g of potassium carbonate, and react at 65° C. for 24 h under nitrogen protection. After the reaction, the pH was adjusted to 3.0 with hydrochloric acid, and then extracted with ethanol. The product was vacuum-dried at 100° C. for 5 h to obtain carboxyl-containing chlorinated paraffin 52.

[0039] 2) Preparation of chlorinated paraffin 52 containing acid chloride: add 70 mol of carboxyl-containing chlorinated paraffin 52 to the reaction kettle, add 85 mol of phosphorus trichloride dropwise, stir and heat up to 70°C, react for 4 hours, cool to room temperature, and stand for stratification The chlorinated paraffin 52 containing the acid chloride was obtained.

[0040]3) Preparation of isocyanurate-modified chlorinated paraffin 52 monohydric alcohol: add 100mol tris(2-hydroxyethyl)isocyanura...

Embodiment 3

[0045] 1) Preparation of carboxyl-containing chlorinated paraffin 52: Dissolve 20 g of chlorinated paraffin 52 in 200 mL of acetone, stir to dissolve, add 20 g of p-hydroxybenzoic acid and 23 g of potassium carbonate, and react at 65° C. for 24 h under nitrogen protection. After the reaction, the pH was adjusted to 3.0 with hydrochloric acid, and then extracted with ethanol. The product was vacuum-dried at 100° C. for 5 h to obtain carboxyl-containing chlorinated paraffin 52.

[0046] 2) Preparation of chlorinated paraffin 52 containing acid chloride: add 70 mol of chlorinated paraffin 52 containing carboxyl group to the reaction kettle, add 85 mol of phosphorus trichloride dropwise, stir and heat up to 60°C, react for 5 hours, cool to room temperature, and let stand to separate The chlorinated paraffin 52 containing the acid chloride was obtained.

[0047] 3) Preparation of isocyanurate-modified chlorinated paraffin 52 monohydric alcohol: add 100mol tris(2-hydroxyethyl)isocya...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap