Multi-initial-state fuel transient reaction flow field parameter testing system

A transient response and parameter testing technology, applied in the direction of material thermal development, material explosion, etc., can solve the problems of small contribution, complex operation, low integration and automation level, etc., to ensure sealing, simple operation, and system integration effect with a high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

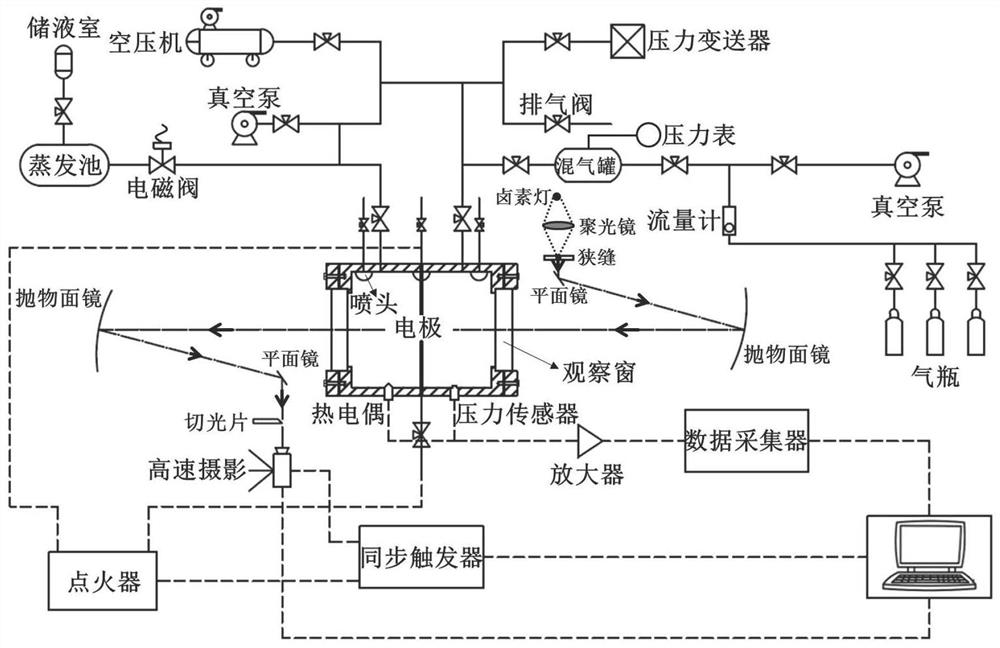

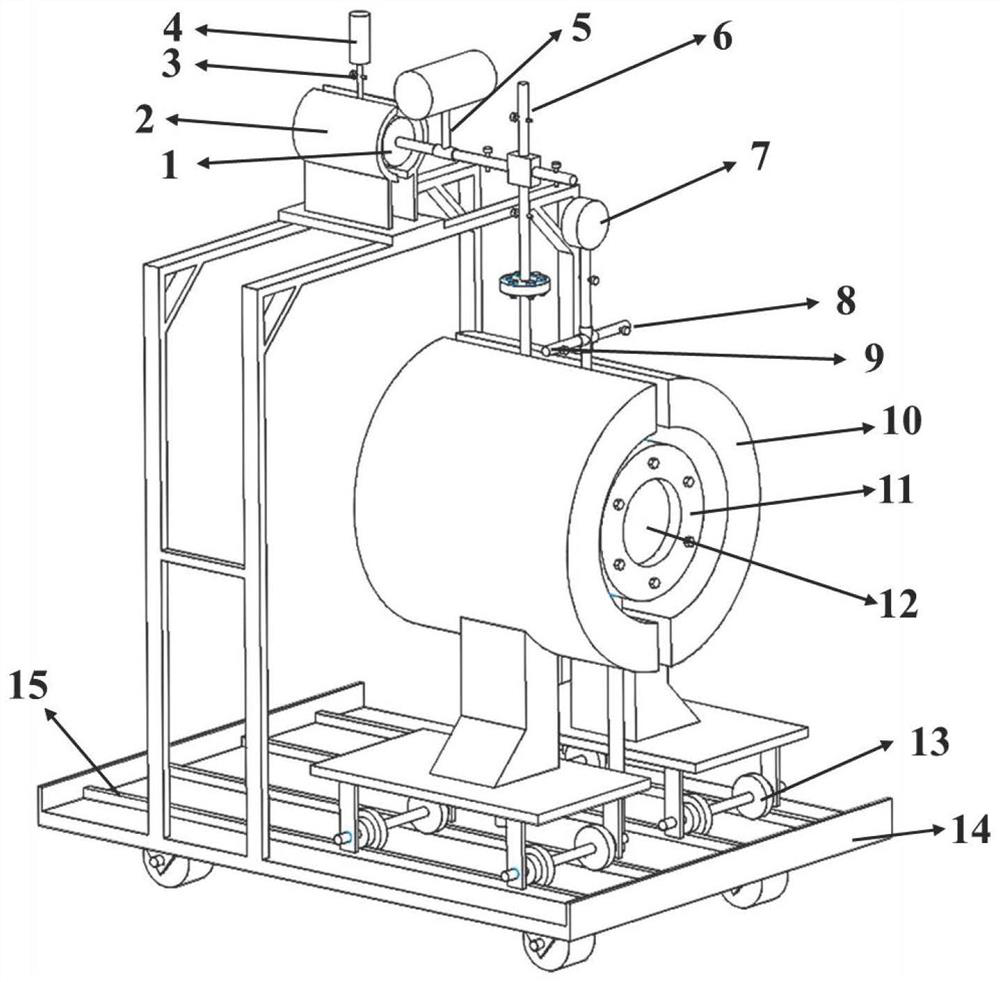

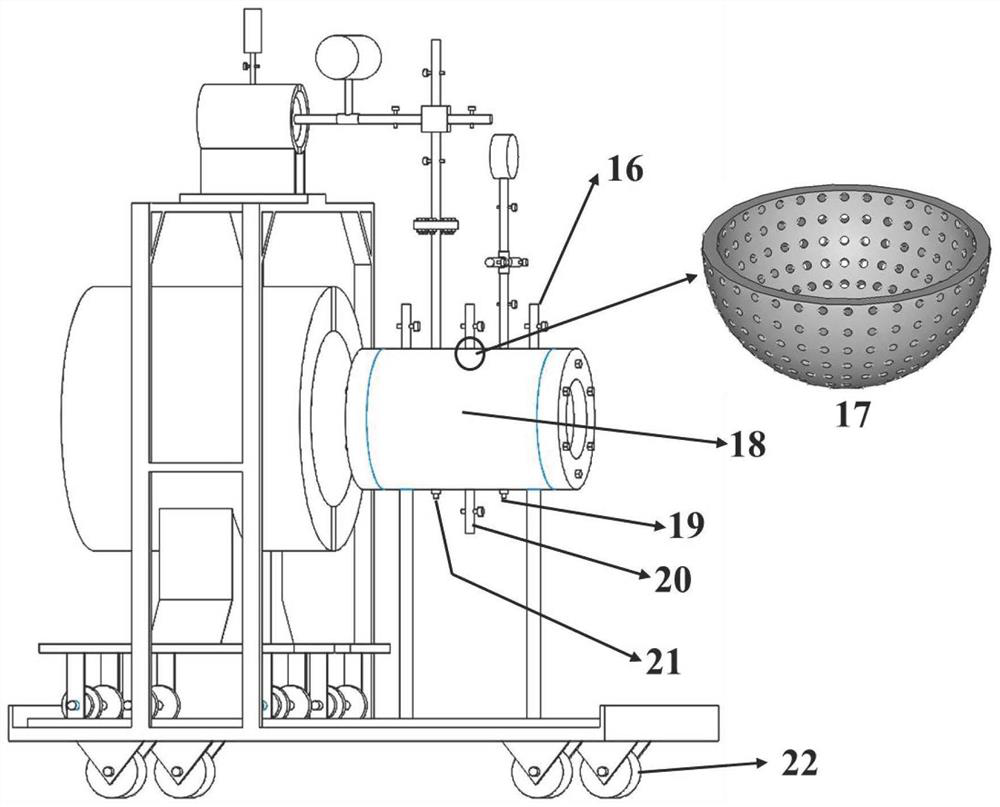

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Ether / oxygen mixture explosion flow field test

[0037] Apply the present invention to carry out ether / oxygen mixture explosion flame test, initial state: P 0 = 1 bar, T 0 =400K, fuel equivalent ratio Follow the steps below:

[0038] 1. Experimental preparation: Calculate the initial state according to Dalton's law of partial pressure, and obtain the partial pressure of ether as P 1 , the partial pressure of oxygen is P 2 (P 0 =P 1 +P 2 ), T 0 =400K; set up the experimental device and check the reliability of each system, adjust the optical path of the optical imaging system; turn on the evaporation pool heater (2) and the reaction chamber heater (10), the preset temperature is 400K and reach the heat supply balance, the liquid storage room ( 4) Fill it with ether and check the airtightness of the system, and then evacuate the whole system to vacuum (the reading on the pressure transmitter is zero, which is gauge pressure).

[0039] 2. Gas distribut...

Embodiment 2

[0043] Example 2: Acetylene / hydrogen / air mixture explosion flow field test

[0044] Apply the present invention to carry out acetylene / hydrogen / air mixture explosion flame test, initial state: P 0 =0.2~2.0bar, T 0 =300~600K, fuel equivalent ratio Acetylene and hydrogen volume ratio f=1, operate according to the following steps:

[0045] 1. Experimental preparation: Calculate the initial state according to Dalton's law of partial pressure, and the partial pressure of acetylene is P 1 , the hydrogen partial pressure is P 2 , the air partial pressure is P 3 (P 0 =P 1 +P 2 +P 3 ), T 0 =300~600K; set up the experimental device and check the reliability of each system, adjust the optical path of the optical imaging system; turn on the reaction chamber heater (10), and the preset temperature is the initial temperature T of the experiment 0 And reach the heat supply balance, close all the valves of the liquid vapor entering the reaction chamber and check the airtightness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com