Pre-lithiated silicon-oxygen negative electrode material as well as preparation method and application thereof

A technology for pre-lithiation of silicon oxide and negative electrode materials, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problem of first-time coulombic efficiency reduction, achieve excellent battery life, high surface density, and accelerate pre-lithiation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

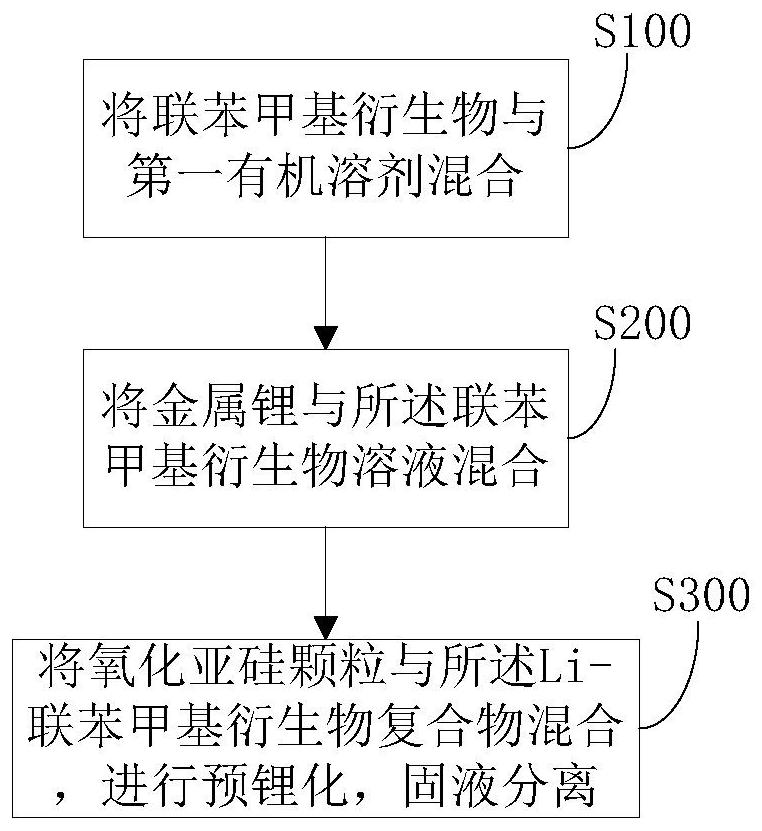

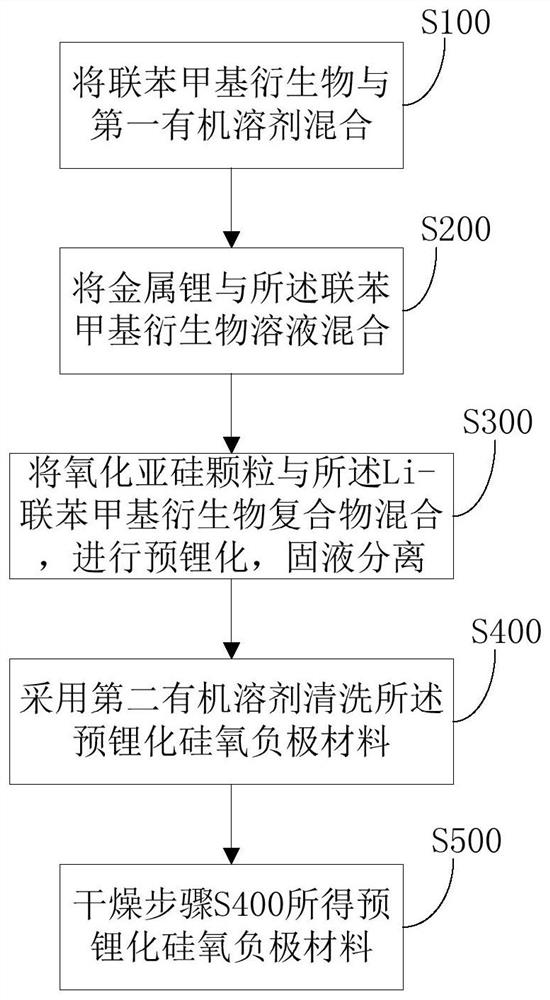

Method used

Image

Examples

preparation example Construction

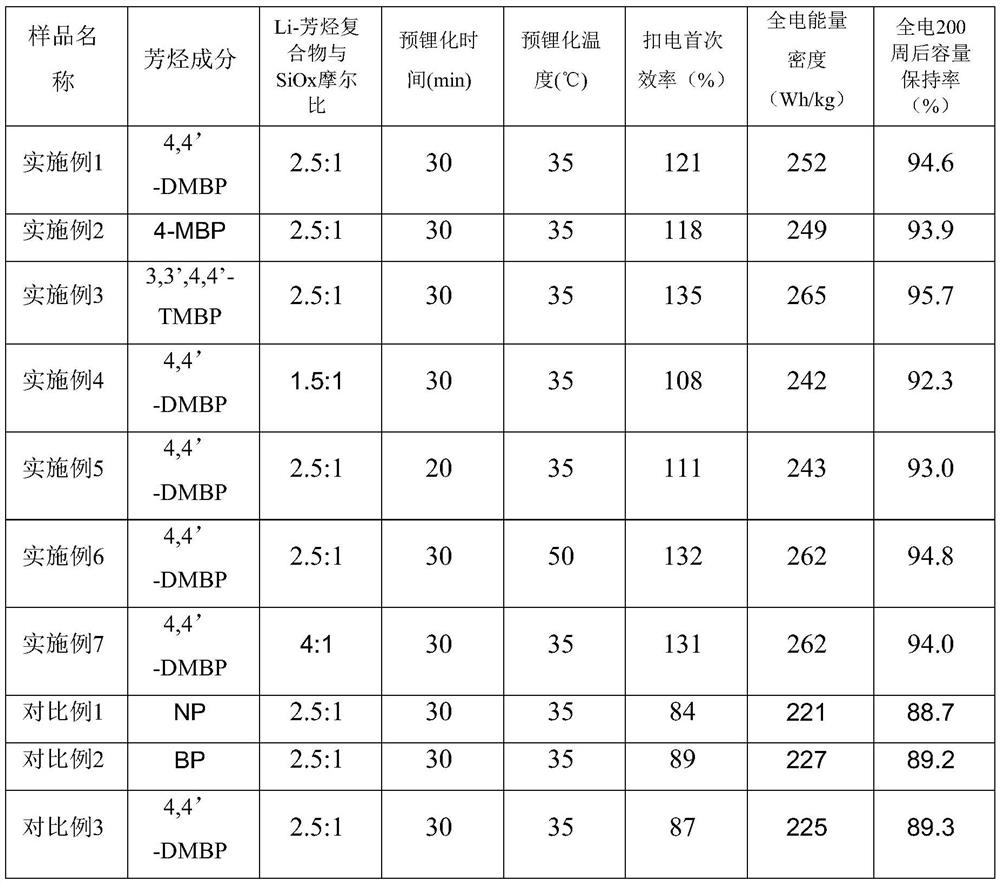

[0064] According to the method for preparing a pre-lithiated silicon-oxygen negative electrode material according to an embodiment of the present invention, the silicon-based negative electrode particles with a particle size of micron are soaked in a solution using a Li-biphenylmethyl derivative compound as a chemical pre-lithiation reagent , the lithium ions in the composite contact with the silicon-oxygen negative electrode particles to form a pre-lithiated silicon-oxygen negative electrode material with artificial SEI film on the surface and lithium intercalation inside. Since the operation object of this pre-lithiation process is micron-sized silicon-oxygen negative electrode particles, in the chemical pre-lithiation process, the formation of artificial SEI film on the surface and the formation of silicon-oxygen particles can be completed quickly after contacting the liquid-phase pre-lithiation reagent. Lithium intercalation phase, to achieve the purpose of pre-lithiation. ...

Embodiment 1

[0077] In the glove box, lithium flakes were added to a 0.5 mol / L solution of 4,4'-dimethylbiphenyl (4,4'-DMBP) in methyl butyl ether, where Li was mixed with 4, The molar ratio of 4'-DMBP was set at 4:1, and the Li-4,4'-DMBP complex was obtained by stirring thoroughly, which was used as a chemical pre-lithiation reagent.

[0078] Put the silicon oxide negative electrode particles with a D50 of 10 μm into the above chemical pre-lithiation reagent, according to the Li-4,4’-DMBP complex and SiO x The molar ratio of 2.5:1 was added to the pre-lithiation reagent to add silicon-oxygen negative electrode particles.

[0079] At a temperature of 35°C, the pre-lithiation holding time is 30 minutes, the pre-lithiated silicon oxide negative electrode particles are separated from the pre-lithiated reagent by filtration, washed with propylene carbonate, and dried at 80°C to obtain the pre-lithiated silicon oxide negative electrode Material.

[0080] After mixing the above-mentioned pre-l...

Embodiment 2

[0083] The difference from Example 1 is that the aromatic hydrocarbon used is 4-methylbiphenyl (4-MBP), and the other contents are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com