Preparation method of trans-1, 3-dichloropropene

A dichloropropene and reaction technology, which is applied in the field of preparation of trans-1,3-dichloropropene, can solve the problems of high separation difficulty, high energy consumption, low economic value, no mention, etc., and achieves easy industrial implementation, The effect of less discharge of three wastes and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

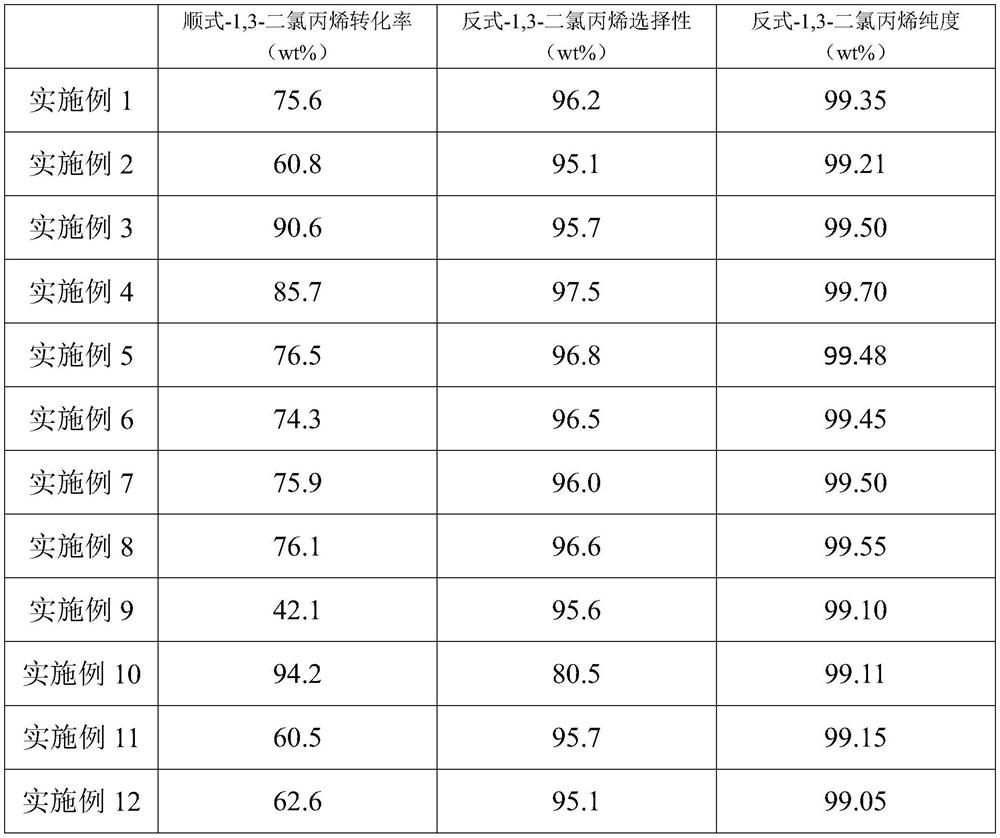

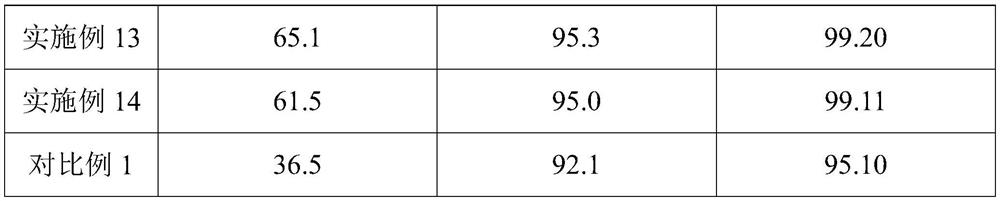

Examples

Embodiment 1

[0048] This embodiment provides a preparation method of trans-1,3-dichloropropene, the preparation method comprising the following steps:

[0049] (1) mixed reaction raw material (80.1wt% cis-1,3-dichloropropene and 17.8wt% trans-1,3-dichloropropene) and nano titanium dioxide as catalyst, the mass ratio of reaction raw material and catalyzer is 1:0.03, heat up to 30°C, and react for 3 hours under the condition of 20W, 310nm LED ultraviolet light to prepare trans-1,3-dichloropropene;

[0050] (2) The product containing trans-1,3-dichloropropene obtained after the reaction is separated by rectification, the vacuum degree of rectification separation is -0.070~-0.072MPa, and the temperature at the top of the tower is 64~65°C, The temperature at the bottom of the tower is 72-75°C, the reflux ratio is 3.2-3.5:1, and cis-1,3-dichloropropene and trans-1,3-dichloropropene are produced sequentially from the top of the tower.

Embodiment 2

[0052] This embodiment provides a preparation method of trans-1,3-dichloropropene, the preparation method comprising the following steps:

[0053] (1) Mixed reaction raw materials (55.6wt% cis-1,3-dichloropropene and 43.4wt% trans-1,3-dichloropropene) and nano-alumina as catalyst, the mass ratio of reaction raw materials to catalyst The ratio is 1:0.05, the temperature is raised to 50°C, and the reaction is carried out under the condition of 50W, 310nm LED light for 2 hours to prepare trans-1,3-dichloropropene;

[0054] (2) The product containing trans-1,3-dichloropropene obtained after the reaction is separated by rectification, the vacuum degree of rectification separation is -0.065~-0.070MPa, and the temperature at the top of the tower is 65~67°C, The temperature at the bottom of the tower is 75-77°C, the reflux ratio is 3-3.3:1, and the cis-1,3-dichloropropene and trans-1,3-dichloropropene are produced sequentially from the top of the tower.

Embodiment 3

[0056] This embodiment provides a preparation method of trans-1,3-dichloropropene, the preparation method comprising the following steps:

[0057] (1) mixed reaction raw material (95.6wt% cis-1,3-dichloropropene and 2.7wt% trans-1,3-dichloropropene) and cadmium sulfide as catalyst, the mass ratio of reaction raw material and catalyzer is 1:0.1, the temperature was raised to 75°C, and the reaction was carried out under natural light conditions for 1 hour to prepare trans-1,3-dichloropropene;

[0058] (2) The product containing trans-1,3-dichloropropene obtained after the reaction is separated by rectification, the vacuum degree of rectification separation is -0.070~-0.075MPa, and the temperature at the top of the tower is 66~68°C, The temperature at the bottom of the tower is 70-73°C, the reflux ratio is 4.3-5:1, and cis-1,3-dichloropropene and trans-1,3-dichloropropene are produced sequentially from the top of the tower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com